Bearing lubrication, Lubricating-oil requirements – Goulds Pumps 3296 EZMAG - IOM User Manual

Page 43

Commissioning, Startup, Operation, and Shutdown

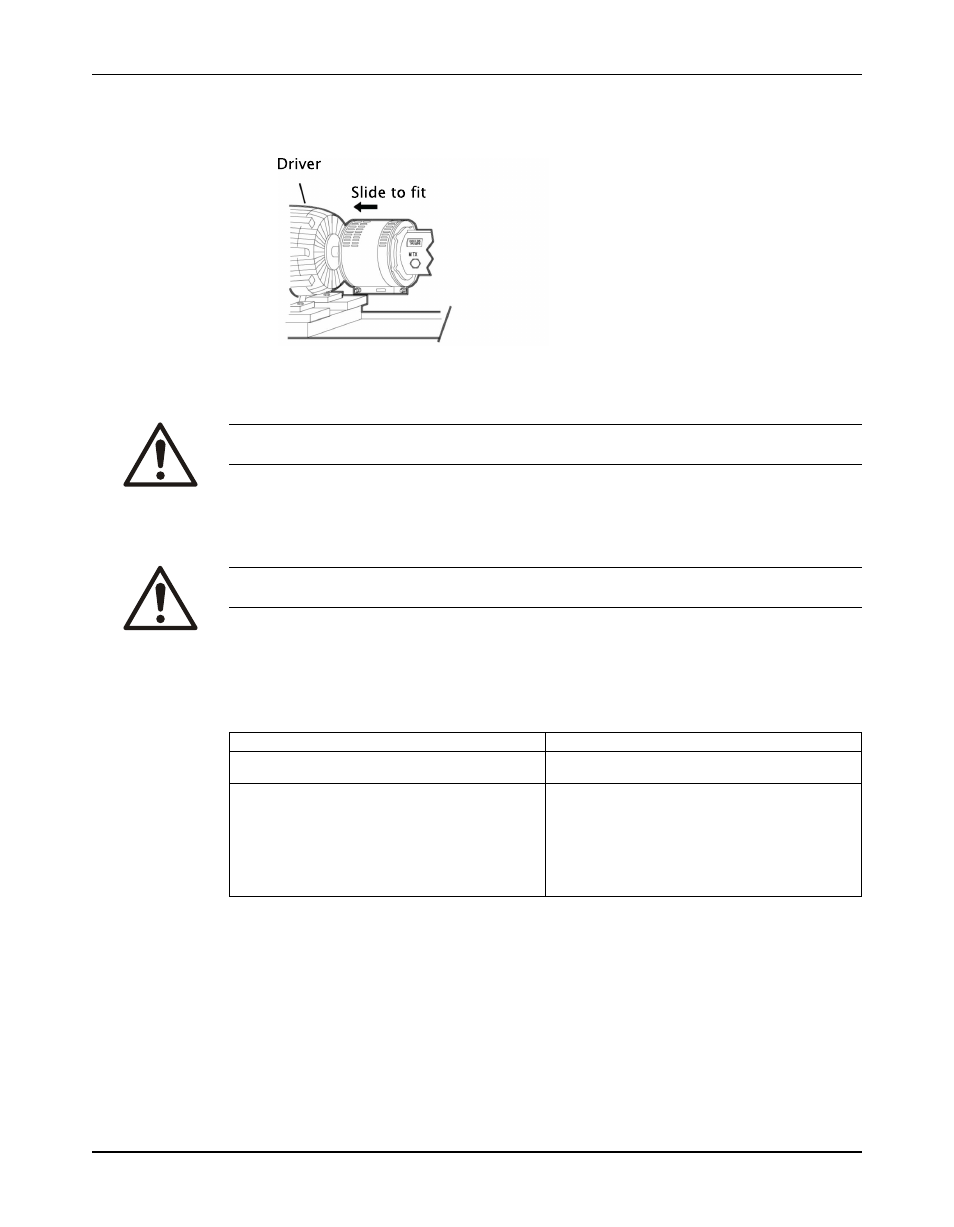

9. Slide the driver-half of the coupling guard towards the motor so that the coupling guard

completely covers the shafts and coupling.

10. Use a nut, a bolt, and two washers to secure the coupling guard halves together.

11. Tighten all nuts on the guard assembly.

WARNING:

Never operate the pump without the coupling guard correctly installed.

Bearing lubrication

WARNING:

Pumps are shipped without oil. Oil-lubricated anti-friction bearings must be lubricated at the job site.

These bearing lubrication sections list different pumped-fluid temperatures. If your pump is

ATEX certified and your pumped-fluid temperature exceeds the permitted temperature values,

then consult your ITT representative.

Lubrication requirements

Pump type

Requirements

Close coupled

Close-coupled pumps do not have bearings that

require lubrication.

Frame mounted

• The oil level is measured through the sight

glass.

• The oil level must not fall below the center of

the sight glass.

• An increase in oil level may be noted after

startup due to oil circulation within the bearing

frame.

Lubricating-oil requirements

Oil quality requirements

Use a high-quality turbine oil with rust and oxidation inhibitors with rated viscosity shown below

at 100°F (38°C).

Model 3296 EZMAG Installation, Operation, and Maintenance Manual

41