Specifications – NOVUS Controller N120 User Manual

Page 9

NOVUS AUTOMATION

9/14

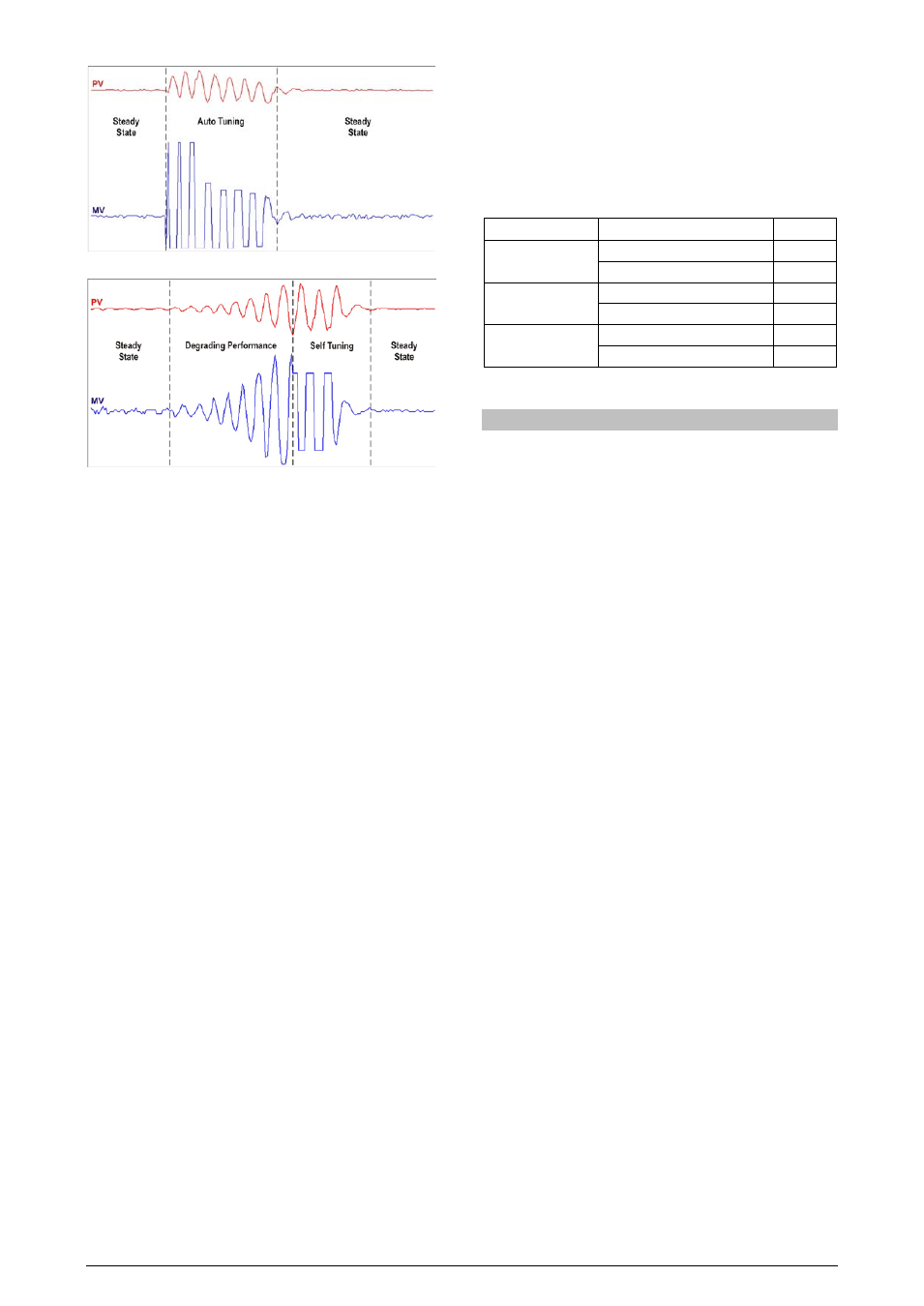

Fig. 7 – Example of auto tuning

Fig. 8 - Example of auto-adaptative tuning

The operator may select, through the ATUN parameter, the desired

tuning type among the following options:

• OFF: The controller does not carry through automatic tuning or

auto-adaptative tuning. The PID parameters will not be

automatically determined nor optimized by the controller.

• FAST: The controller will accomplish the process of automatic

tuning one single time, returning to the OFF mode after

finishing. The tuning in this mode is completed in less time, but

not as precise as in the FULL mode.

• FULL: The same as the FAST mode, but the tuning is more

precise and slower, resulting in better performance of the P.I.D.

control.

• SELF: The performance of the process is monitored and the

auto-adaptative tuning is automatically initiated by the

controller whenever the performance becomes poorer.

After the tuning process, the controller enters a learning phase

when it collects data relative to the process performance. This

phase, which is dependent of the response time of the process,

is indicated by a flashing TUNE indicator. Once this learning is

completed, the controller is able to decide whether of not a new

tuning is required to improve system response.

It is recommended not to turn the controller off neither change

the SP value during this phase.

• rSLF: Accomplishes the automatic tuning and returns into the

SELF mode. Typically used to force an immediate automatic

tuning of a controller that was operating in the SELF mode,

returning to this mode at the end.

• TGHT: Similar to the SELF mode, but in addition to the auto-

adaptative tuning it also executes the automatic tuning

whenever the controller is set in RUN=YES or when the

controller is turned on.

Whenever the parameter ATUN is altered by the operator into a value

different from OFF, an automatic tuning is immediately initiated by the

controller (if the controller is not in RUN=YES, the tuning will begin

when it passes into this condition). The accomplishment of this

automatic tuning is essential for the correct operation of the auto-

adaptative tuning.

The methods of automatic tuning and auto-adaptative tuning are

appropriate for most of the industrial processes. However, there may

be processes or even specific situations where the methods are not

capable to determine the controller's parameters in a satisfactory

way, resulting in undesired oscillations or even taking the process to

extreme conditions. The oscillations themselves imposed by the

tuning methods may be intolerable for certain processes. These

possible undesirable effects must be considered before beginning the

controller's use, and preventive measures must be adopted in order

to assure the integrity of the process and users.

The “TUNE” signaling device will stay on during the tuning process.

In the case of PWM or pulse output, the quality of tuning will also

depend on the cycle time adjusted previously by the user.

If the tuning does not result in a satisfactory control, refer to Table 7

for guidelines on how to correct the behavior of the process.

PARAMETER

VERIFIED PROBLEM

SOLUTION

Proportional Band

Slow answer

Decrease

Great oscillation

Increase

Rate of Integration

Slow answer

Increase

Great oscillation

Decrease

Derivative Time

Slow answer or instability

Decrease

Great oscillation

Increase

Table 07 - Guidance for manual adjustment of the PID parameters

SPECIFICATIONS

DIMENSIONS: .................................................................. 100 x 67 mm

.............................................................. Approximate Weight: 80 g

POWER SUPPLY:........... 100 to 240 Vac/dc (±10 %), 50/60 Hz, 5 VA

ENVIRONMENTAL CONDITIONS:

Operation Temperature: ............................................... 5 to 60 °C

Relative Humidity: ................................................ 80% max. 30 ºC

For temperatures above 30 ºC, reduce 3% for each ºC

INPUT ............. T/C, Pt100, voltage and current (according to Table 2)

Internal Resolution: .................................. 32767 levels (15 bits)

Resolution of Display: ..... 12000 levels (from - 1999 up to 9999)

Rate of input reading: ................................. up to 55 per second

Precision: .. Thermocouples J, K, T, E: 0.25% of the span ±1 ºC

.................... Thermocouples N, R, S, B: 0.25% of the span ±3 ºC

................................................................. Pt100: 0.2% of the span

............................................... 0-50 mV, 0-5 Vdc: 0.2% of the span

Input Impedance: 0-50 mV, Pt100 and Thermocouples: >10 MΩ

................................................................................. 0-5 V: >1 MΩ

Measurement of Pt100: ................ Three wire type, (α=0.00385)

with compensation for cable length, excitation current of

0.170 mA

All input and output types are factory-calibrated. Thermocouples

according to standard NBR 12771 / 99, RTD’s NBR 13773 / 97.

Heating Time: ..................................................................... 15 minutes

ENTRADA DIGITAL(DIG INP): .. Contato Seco ou NPN coletor aberto

OUT1: ..................................................... Pulso de tensão, 5 V / 20 mA

OUT2 (*): ..................................................... Relé SPST, 3 A / 250 Vca

OUT3: .......................................................... Relé SPST, 3 A / 250 Vca

(*) In models with adjustable outputs – PR, one relay SPDT-NO 10 A

/ 250 VAC is available at OUT2. These models will not be available

the OUT3.

USB INTERFACE: 2.0, CDC CLASS (virtual communications port),

MODBUS RTU protocol.

SUITABLE FOR TERMINAL CONNECTION TYPE FORK

CYCLE PWM PROGRAMMABLE FROM 0.5 TO 100 SECONDS;

STARTS UP OPERATION: after 3 seconds connected to the power

supply.