Access password, Protection of the access code, Master password – NOVUS Controller N120 User Manual

Page 8: Programs of ramp and soak, Link of programs, Event alarm, Determination of pid parameters

NOVUS AUTOMATION

8/14

ACCESS PASSWORD:

The protected levels, when accessed, request the user to provide the

Access Password for granting permission to change the

configuration of the parameters on these cycles.

The prompt PASS precedes the parameters on the protected levels.

If no password is entered, the parameters of the protected cycles can

only be visualized.

The Access Code is defined by the user in the parameter Password

Change (PAS.(), present in the Calibration level. The factory default

for the password code is 1111.

PROTECTION OF THE ACCESS CODE

The protection system built into the controller blocks for 10 minutes

the access to protected parameters after 5 consecutive frustrated

attempts of guessing the correct password.

MASTER PASSWORD

The Master Password is intended for allowing the user to define a

new password in the event of it being forgotten. The Master

Password doesn’t grant access to all parameters, only to the

Password Change parameter (PAS(). After defining the new

password, the protected parameters may be accessed (and modified)

using this new password.

The master password is made up by the last three digits of the serial

number of the controller added to the number 9000.

As an example, for the equipment with serial number 07154321, the

master password is 9 3 2 1.

PROGRAMS OF RAMP AND SOAK

This feature allows the creation of Ramp and Soak Setpoint Profiles

(Programs). Up to 20 different profiles with 9 segments each can

be programmed. Longer profiles of up to 180 segments can be

created by linking 2 or more profiles together.

The figure below displays a profile model:

Fig. 4 - Example of a Ramp and Roak

Once a profile is defined and selected for execution (parameter EPr

in the operating level), the controller starts to generate the SP profile

automatically in accordance with the elaborated program.

To execute a profile with fewer segments just program 0 (zero) for the

time intervals that follow the last segment to be executed.

SV

Time

T1

T2

T3

SP0

SP1

SP2

SP3

T4=0

Fig. 5 - Program example with few segments

The program tolerance defines the maximum deviation between PV

and SP for the execution of the profile. If this deviation is exceeded,

the program will be halted until the deviation falls to within the

tolerance band.

Programming 0 (zero) in the “Ptol” parameter disables the program

tolerance and the profile execution will continue regardless of the PV

value (time priority as opposed to SP priority).

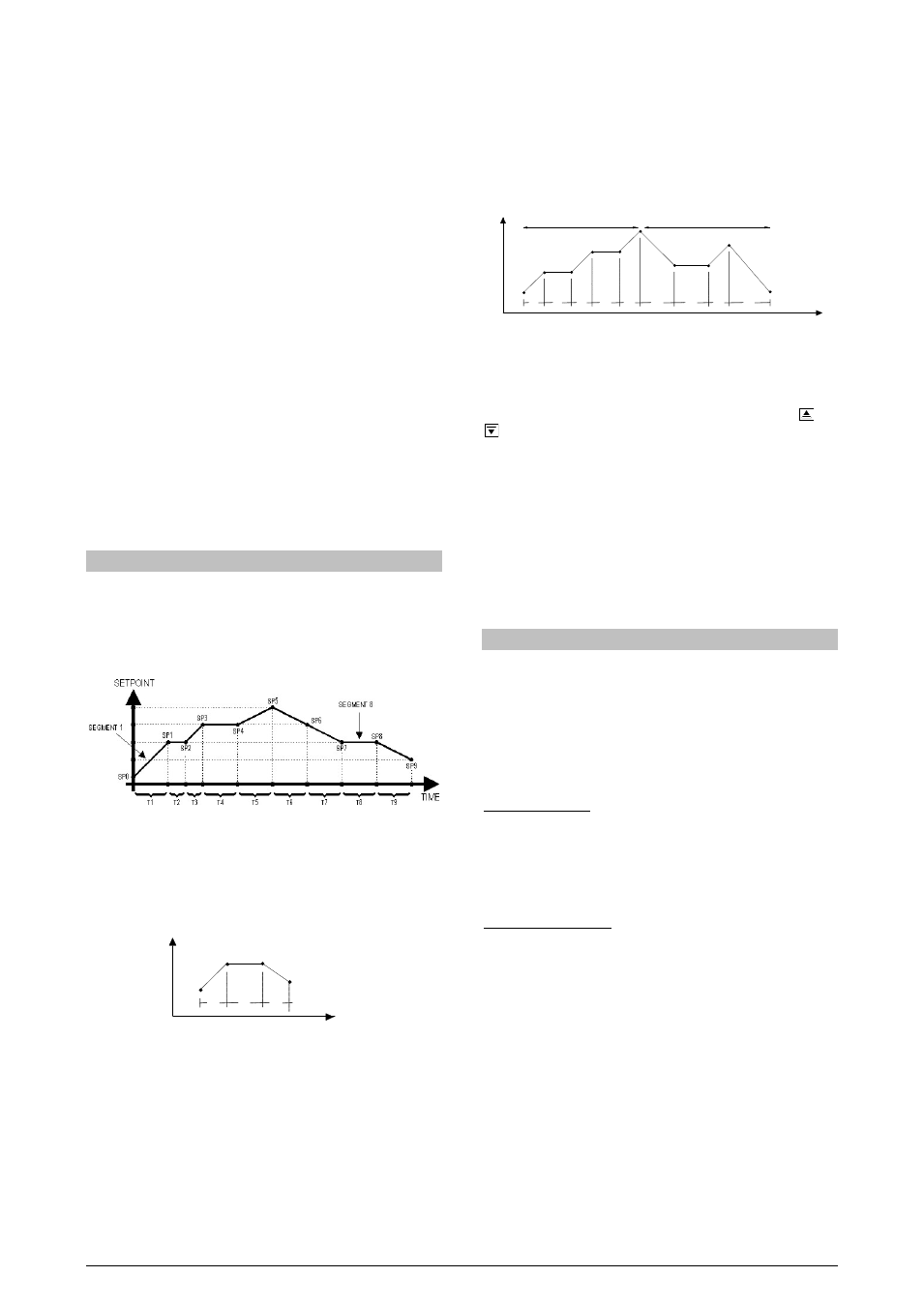

LINK OF PROGRAMS

It is possible to create a more complex program, with up to 180

segments, joining the 20 programs. This way, at the end of a program

execution the controller immediately starts to run the next one, as

indicated in the “LP".

To force the controller to run a given program or many programs

continuously, it is only necessary to link a program to itself or the last

program to the first.

SV

Time

T1

T2

T3

T4

T5

T1

T2

T3

T4

SP0

SP1

SP2

SP3

SP4

SP5 / SP0

SP1 SP2

SP3

SP4

Program 1

Program 2

Fig. 6 - Example of interlinked programs

EVENT ALARM

The Event Alarm function associates the alarms to specific segments

of a program. The information of which alarms are to be activated or

deactivated is given in parameters “ PE1“ to “ PE9. Press the

and

keys until the desired alarm numbers are displayed.

The Event Alarm requires that the Alarm function be configured as

“rS “.

Notes:

1. If PtoL is different than zero, the controller will wait for the PV to

reach the first program set point SP0 in order to start the program

execution. Otherwise, it will start promptly.

2. Should any power failure occur, the controller resumes the

program execution at the beginning of the segment that was

interrupted.

DETERMINATION OF PID PARAMETERS

The determination (or tuning) of the PID control parameters in the

controller can be carried out in an automatic way and auto-adaptative

mode. The automatic tuning is always initiated under request of the

operator, while the auto-adaptive tuning is initiated by the controller

itself whenever the control performance becomes poor.

Only PID parameters (Control Output 1) can be automatically

calculated by N120. Control Output 2 Proportional Band and Overlap

must be manually adjusted.

Automatic tuning: In the beginning of the automatic tuning the

controller has the same behavior of an ON/OFF controller, applying

minimum and maximum performance to the process. Along the tuning

process the controller's performance is refined until its conclusion,

already under optimized PID control. It begins immediately after the

selection of the options FAST, FULL, RSLF or TGHT, defined by the

operator in the parameter ATUN.

Auto-adaptive tuning: Is initiated by the controller whenever the

control performance is worse than the one found after the previous

tuning. In order to activate the performance supervision and auto-

adaptative tuning, the parameter ATUN must be adjusted for SELF,

RSLF or TGHT. The controller's behavior during the auto-adaptative

tuning will depend on the worsening of the present performance. If

the maladjustment is small, the tuning is practically imperceptible for

the user. If the maladjustment is big, the auto-adaptive tuning is

similar to the method of automatic tuning, applying minimum and

maximum performance to the process in ON/OFF control.