Maintenance, Problems with the controller, Calibration of the input – NOVUS Controller N120 User Manual

Page 10: Calibration of the analogical output, Warranty

NOVUS AUTOMATION

10/14

MAINTENANCE

PROBLEMS WITH THE CONTROLLER

Connection errors and inadequate programming are the most

common errors found during the controller operation. A final revision

may avoid loss of time and damages.

The controller displays some messages to help the user identify

problems.

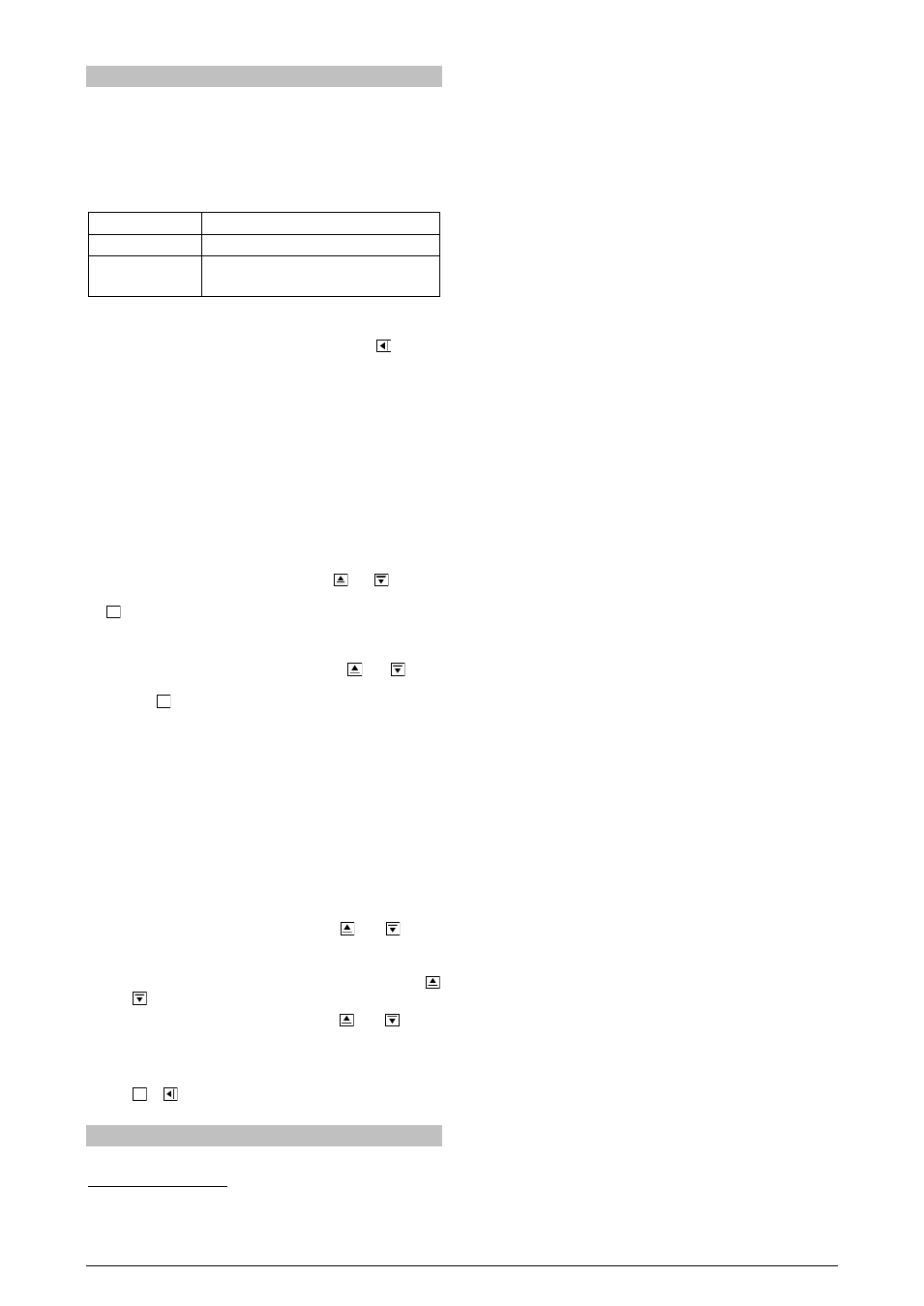

MESSAGE

DESCRIPTION OF THE PROBLEM

----

Open input. No sensor or signal.

Err1

Err6

Connection and/or configuration errors. Check

the wiring and the configuration.

Other error messages may indicate hardware problems requiring

maintenance service. When contacting the manufacturer, inform the

instrument serial number, obtained by pressing the key

for more

than 3 seconds.

CALIBRATION OF THE INPUT

All inputs are factory calibrated and recalibration should only be done

by qualified personnel. If you are not familiar with these procedures

do not attempt to calibrate this instrument.

The calibration steps are:

a) Configure the type of input to be calibrated.

b) Configure the lower and upper limits of indication for the

maximum span of the selected input type.

c) At the input terminals inject a signal corresponding to a known

indication value a little above the lower display limit.

d) Access the parameter “inLC”. With the keys

and

adjust the

display reading such as to match the applied signal. Then press the

P

key.

e) Inject a signal that corresponds to a value a little lower than the

upper limit of indication.

f) Access the parameter “inLC”. With the keys

and

adjust

the display reading such as to match the applied signal. Then

press the

P

key.

Note: When checking the controller calibration with a Pt100

simulator, pay attention to the simulator minimum excitation current

requirement, which may not be compatible with the 0.170 mA

excitation current provided by the N120.

CALIBRATION OF THE ANALOGICAL OUTPUT

• Configure I/O 5 for the current output to be calibrated, be it

control or retransmission.

• In the screen “Ctrl”, program manual mode (

man

).

• Connect a current meter at the analog output.

• Enter the calibration cycle with the correct password.

• Select the screen “ovLC”. Press the keys

and

for the

controller to recognize the calibration process of the current output.

• Read the current indicated on the current meter and adjust the

parameter “ovLC” to indicate this current value (use the keys

and

)

• Select the screen “ovxC”. Press the keys

and

for the

controller to recognize the calibration process of the current output.

• Read the current indicated on the current meter and adjust the

parameter “

ovkC

” to indicate this current value

The key

P

or

in order to leave the screen confirm the

calibration

WARRANTY

Warranty conditions are available on our web site