NOVUS Controller N2000 User Manual

Controller n2000

NOVUS AUTOMATION

1/9

Controller N2000

UNIVERSAL PROCESS CONTROLLER – INSTRUCTIONS MANUAL – V2.1x C

PRESENTATION

The N2000 is a process controller incorporating a PID algorithm and

universal inputs (sensor and standard signals) and outputs (logical,

relay and analog outputs). It holds in one single instrument all de main

features that are needed for the vast majority of industrial processes.

SAFETY SUMMARY

The symbols below are used on the equipment and throughout this

document to draw the user’s attention to important operational and

safety information.

CAUTION or WARNING:

Read complete instructions prior to

installation and operation of the unit.

CAUTION or WARNING:

Electrical Shock Hazard

All safety related instructions that appear in the manual must be

observed to ensure personal safety and to prevent damage to either

the instrument or the system. If the instrument is used in a manner

not specified by the manufacturer, the protection provided by the

equipment may be impaired.

OVER-TEMPERATURE PROTECTION

When designing any control system it is essential to consider what

will happen if any part of the system should fail. In temperature

control applications the primary danger is one in which the heating

remains constantly on. In any application where physical injury or

destruction of equipment might occur, it is recommend to install an

independent protection equipment, with a separate temperature

sensor, to disable the heating circuit in case of overheating. Please

note that the alarm relays within the controller will not give protection

under all failure conditions.

Man 5001132

INSTALLATION

Insert the unit into the panel cut-out and slide the mounting clamp

from the rear to a firm grip at the panel.

RECOMMENDATIONS FOR INSTALLATION

•

Input signal wires should be laid out away from power lines and

preferably inside grounded conduits.

•

Instrument mains (line) supply should be suitable for this purpose

and should not be shared.

•

In controlling and monitoring applications, possible consequences

of any system failure must be considered in advance. The internal alarm

relay does not warrant total protection.

•

Use of RC filters (47 R and 100 nF, serial) are highly recommended

when driving solenoids, contactor coils or other inductive loads.

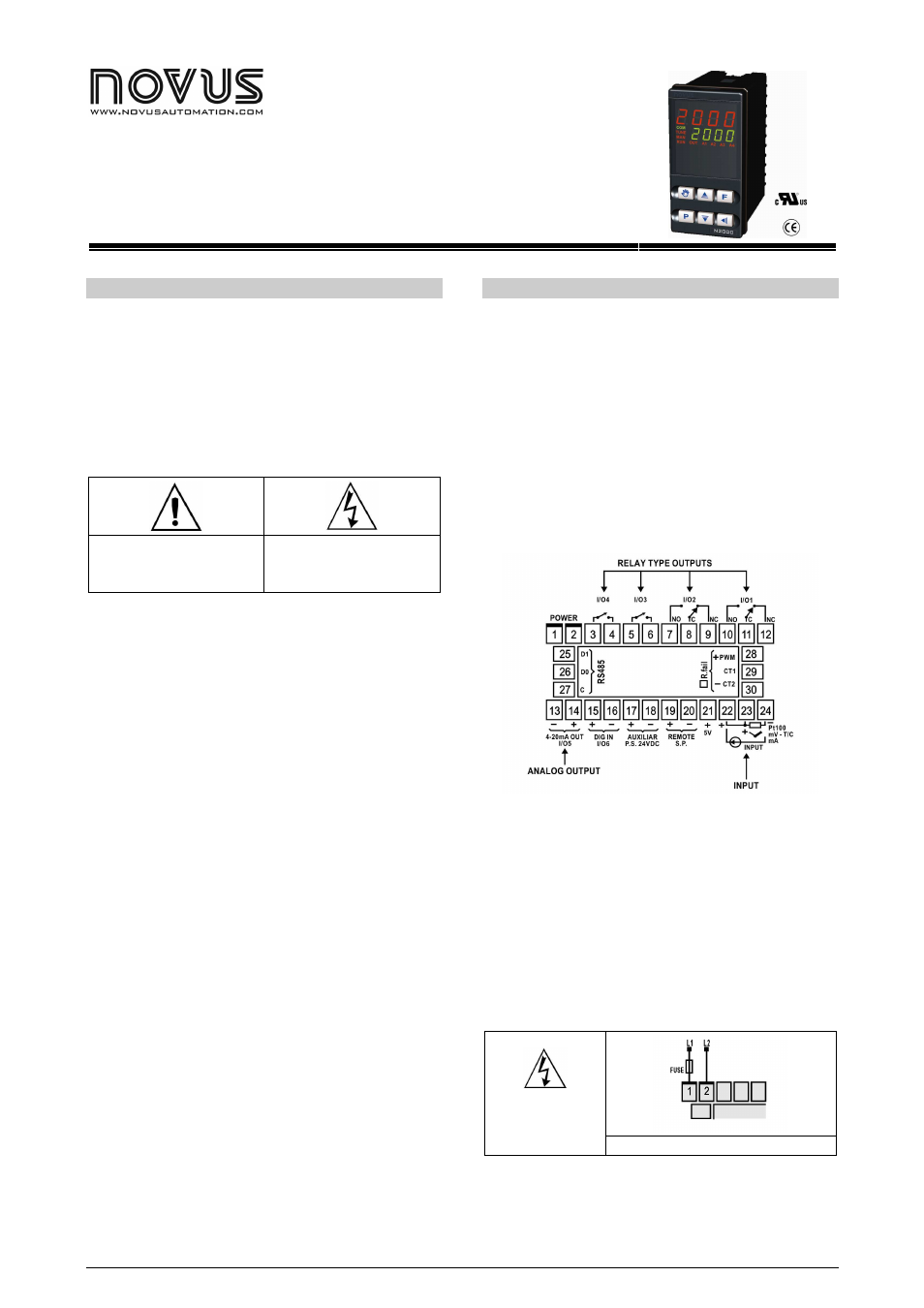

Figure 1 - Backpannel terminals

ELECTRICAL CONNECTIONS

All electrical connections are made to the screw terminals at the rear

of the controller. They accept wire sizes from 0.5 to 1.5 mm2 (16 to

22 AWG). The terminals should be tightened to a torque of 0.4 Nm

(3.5 lb in).

To minimize the pick-up of electrical noise, the low voltage DC

connections and the sensor input wiring should be routed away from

high-current power conductors. If this is impractical, use shielded

cables. In general, keep cable lengths to a minimum.

POWER WIRING

If high voltage is applied to

a low voltage input,

irreversible damage will

occur

Figure 2 – High and Low Voltage AC power wiring