Electrical wiring, Sensor input connections, Description of the parameters – NOVUS Controller N120 User Manual

Page 5: Operation level, E pr, P.seg, T.seg

NOVUS AUTOMATION

5/14

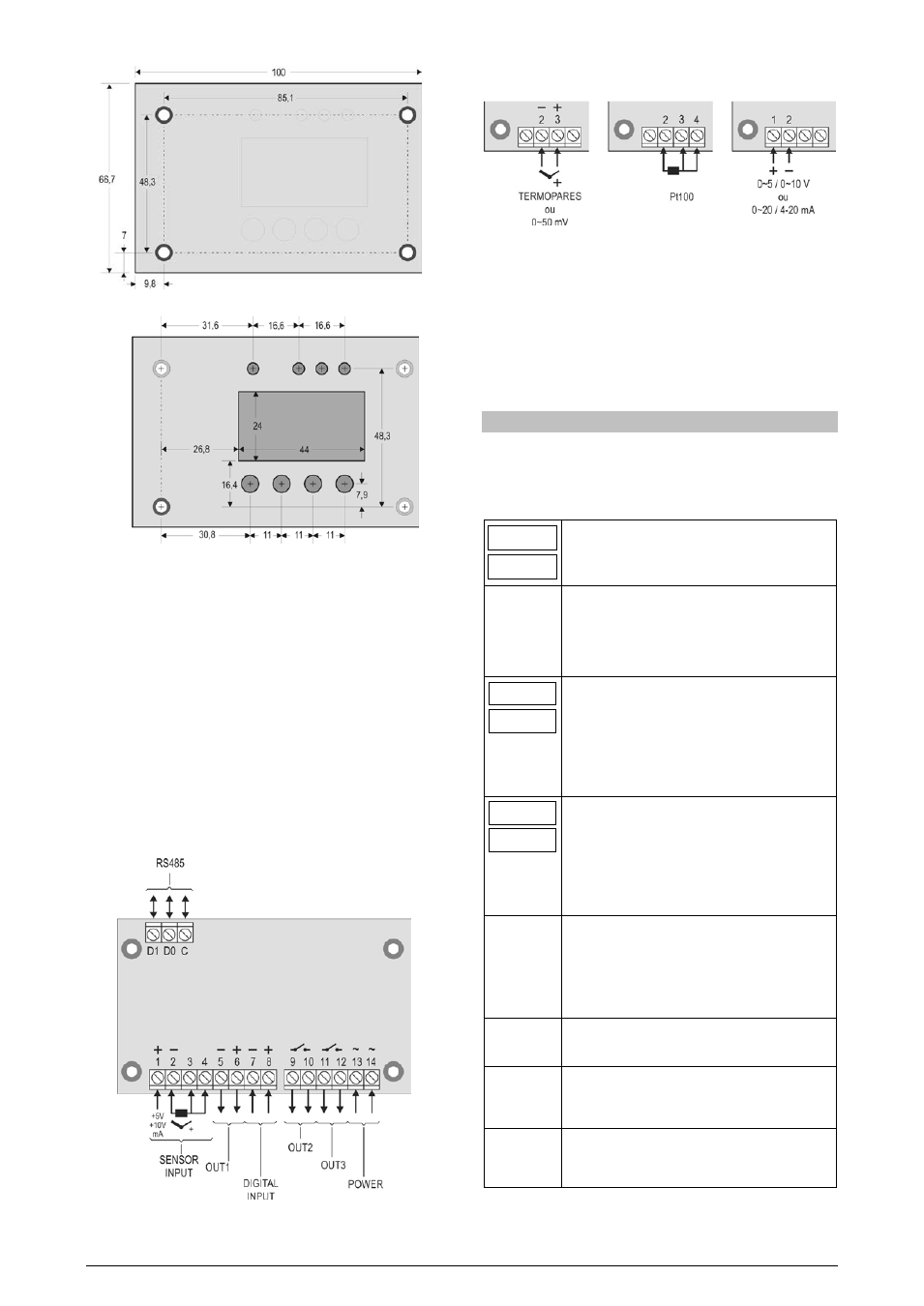

Fig. 2a – Screws mounting holes. Frontal view

Fig. 2b – Keypad, display and leds distances. Front view.

RECOMMENDATIONS FOR THE INSTALLATION

• The input signals conductors shall be positioned throughout the

factory separate from the output and the power supply

conductors, in grounded conduits if possible.

• All electronic instruments must be powered by a clean mains

supply, proper for instrumentation.

• It is strongly recommended to apply RC'S FILTERS (noise

suppressor) to contactor coils, solenoids, etc.

• In any application it is essential to consider what can happen when

any part of the system fails. The controller features by themselves

can not assure total protection.

ELECTRICAL WIRING

Fig. 3a and Fig. 3b: shows the electrical connections.

Fig. 3a – Input, outputs, mains supply and RS485 interface.

Sensor Input Connections

Fig. 3b – Input wiring, outputs, power supply and serial communiction

connections

The input types 0~20 and 4~20 mA are not available in the

controller’s standard model, although shown as an option at the

Type

parameter. These inputs are only available in some custom

models.

The models with 0~20 and 4~20 mA inputs do not accept 0~5 V and

0~10 V inputs types.

DESCRIPTION OF THE PARAMETERS

OPERATION LEVEL

To access the operation level parameters, press the

P key

until the

desired parameter is displays.

Indicação de PV

(Visor Vermelho)

Indicação de SP

(Visor Verde)

PV and SP indication - The upper display shows the

current value of PV. The lower display shows the control

SP value.

(trl

Control Mode -

avto

- Means automatic control mode.

Man - Means manual control mode.

(bumpless transfer between automatic and manual control

modes).

PV Indication

(Red Screen)

MV Indication

(Green Screen)

Manipulated Variable 1 Value (MV) - The upper display

shows PV value and the lower display shows the

percentage of MV1 applied to the control output. When in

manual control, the MV1 value can be changed. When in

auto mode the MV value can only be viewed.

To distinguish the MV1 display from the SP display, the

MV1 is shown flashing intermittently.

PV Indication

(Red Screen)

MV Indication

(Green Screen)

Manipulated Variable 2 Value (MV) - The upper display

shows PV value and the lower display shows the

percentage of MV2 applied to the control output. When in

manual control, the MV2 value can be changed. When in

auto mode the MV value can only be viewed.

To distinguish the MV2 display from the SP display, the

MV2 is shown flashing intermittently.

E pr

Enable Program. Selects the ramp and soak profile

program to be executed.

0 - does not execute program

1 to 20 number of the program to be executed

With enabled outputs (RvN= YES),

the program starts

right after the program is selected.

p.seg

Screen for indication only. When a ramp and soak program

is active, this parameter shows the number of the segment

under execution, from 1 to 9.

t.seg

Screen for indication only. When a ramp and soak

program is in execution, it shows the remaining time to

the end of the current segment, in units of time

configured in the Pr.tb parameter.

rvn

Enables control outputs and alarms.

YES

- Outputs enables.

NO

- Outputs not enabled.