Nor-Lake Refrigeration Systems User Manual

Page 20

09/14 Rev. E 101628

20

1. Check with operation personnel: Always check with the operating personnel who are using

the equipment to see if there have been any reports of abnormal or erratic operation. Frequently

indications of abnormal operation may be observed by operating people who do not realize their

significance, and this information may never be given to the service personnel unless brought

out by specific questions concerning system operation. Ask particularly about trips of the oil

pressure safety control, or other safety devices.

2. Operating pressures and temperatures: If permanent gauges are available, check the

compressor suction and discharge pressures to be sure they are within the normal range for the

application and the temperature of the condensing medium. If there are any indications of

abnormal operation such as short cycling on pressure controls or excessive compressor

temperatures, use a gauge manifold to check the operating pressures on systems without

permanently installed gauges. If abnormal operating pressures are found, the cause must be

determined and the malfunction corrected. Check the compressor head temperature by touch.

An abnormally cool head can indicate a broken discharge valve, a blown or improper head

gasket, or inadequate compressor cooling.

3. Oil level and condition: On Copeland semi hermetic compressors, the oil level should be at or

slightly above the center of the sight glass. It should be kept in mind that some slight fluctuation

in oil level may occur during an operating cycle particularly before and after defrost periods. As

long as the oil level is maintained well within the sight glass such fluctuations are not harmful.

a. If the oil is black in color, the crankcase should be drained and the oil replaced. If

there has been a recent compressor failure on the system and the oil has an acid

odor, a fresh filter drier should be installed in the suction line and left in the line for a

period of 48 hours and then must be removed.

b. If the oil is still discolored, the oil and the suction line filter drier element should again

be changed. This procedure should be continued until the oil remains clean, odor

free, and the color approaches that of new oil. The filter drier element then may be

replaced with a permanent type suction line filter.

It is recommended that only mineral oil (MO) or Alkyl Benzene oil (AB) be used in compressors.

ONLY Polyol Ester oils (POE) used in R-404A compressors. DO NOT use POE oils in systems

if the system came pre-charged with mineral oil. Table 6 below references the appropriate oil for

the type of refrigerant used. This data is from Copeland specifications and is RIE recommended

oil for their product.

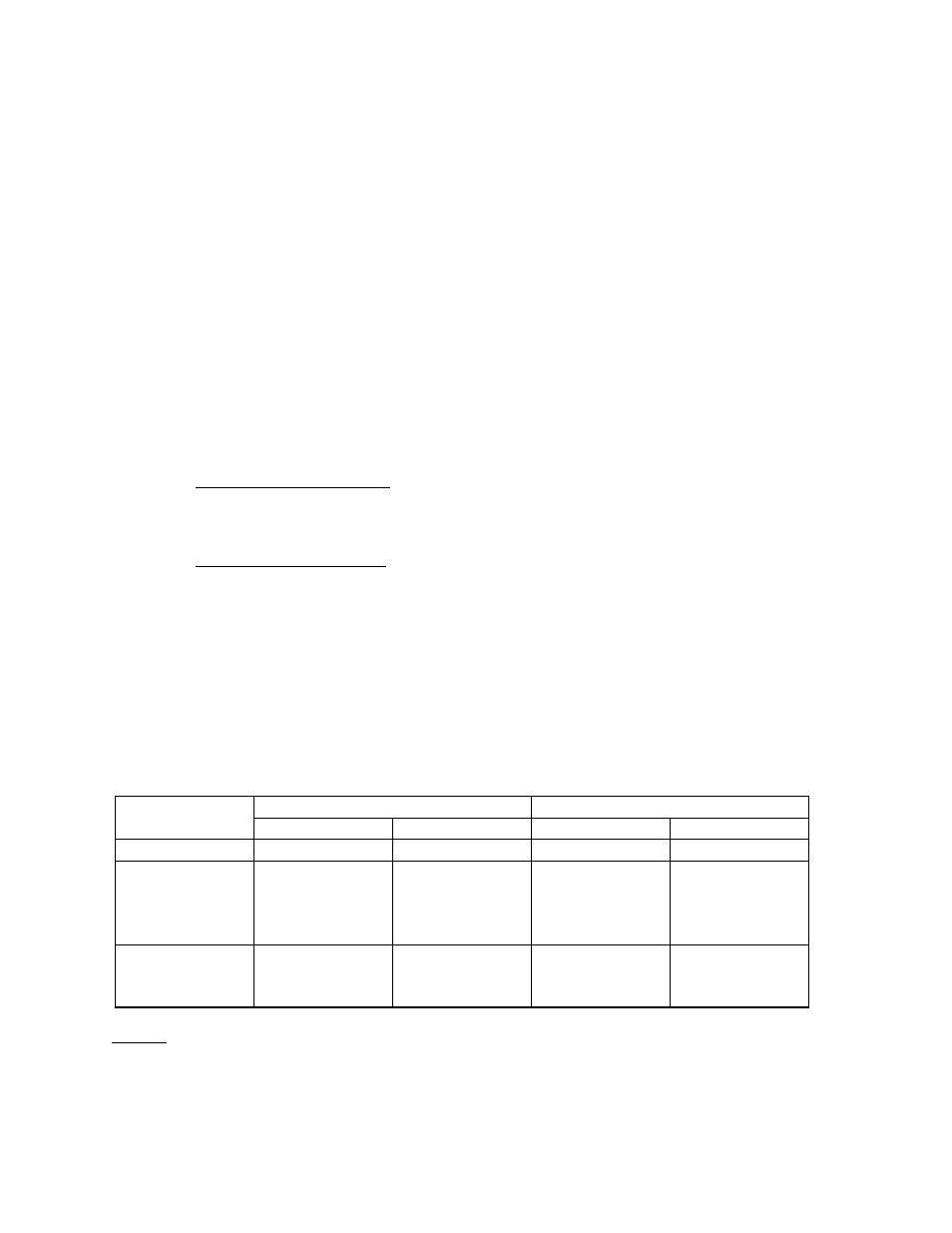

TABLE 6

Refrigerant

Lubricants

Type

Source

Preferred

Alternate

Ozone Depleting

HCFC

Many

MO

AB & MO

Interims

HCFC R-401A

Dupont/Allied

AB & MO

POE & MO

HCFC R-401B

Dupont/Allied

AB & MO

POE & MO

HCFC R-402A

Dupont

AB & MO

POE & MO

HCFC R-408A

Atochem

AB & MO

POE & MO

Non-Ozone

Depleting

HFC R-134a

Many

POE

HFC R-404A

Many

POE

HFC E-507

Allied

POE

Legend:

MO = Mineral Oil (3GS or Equivalent)

AB = Alkyl Benzene ( Zerol 200 TD)

POE = Mobil EAL™ Arctic 22 CC or ICI Emkarate™ RL32CF

POE & MO = Minimum 50% POE

AB & MO = Minimum 50% Alkyl Benzene (Shell 22-12)

Note: Shell 2212 is a 70/30 mixture of AB and MO. Zerol 200 TD is 100% AB

Note: Unless there are reasons for changing the oil, as outlined earlier in this section, the

refrigerant oil should not be changed. It does not deteriorate or wear out with normal usage.