Nor-Lake Refrigeration Systems User Manual

Page 12

09/14 Rev. E 101628

12

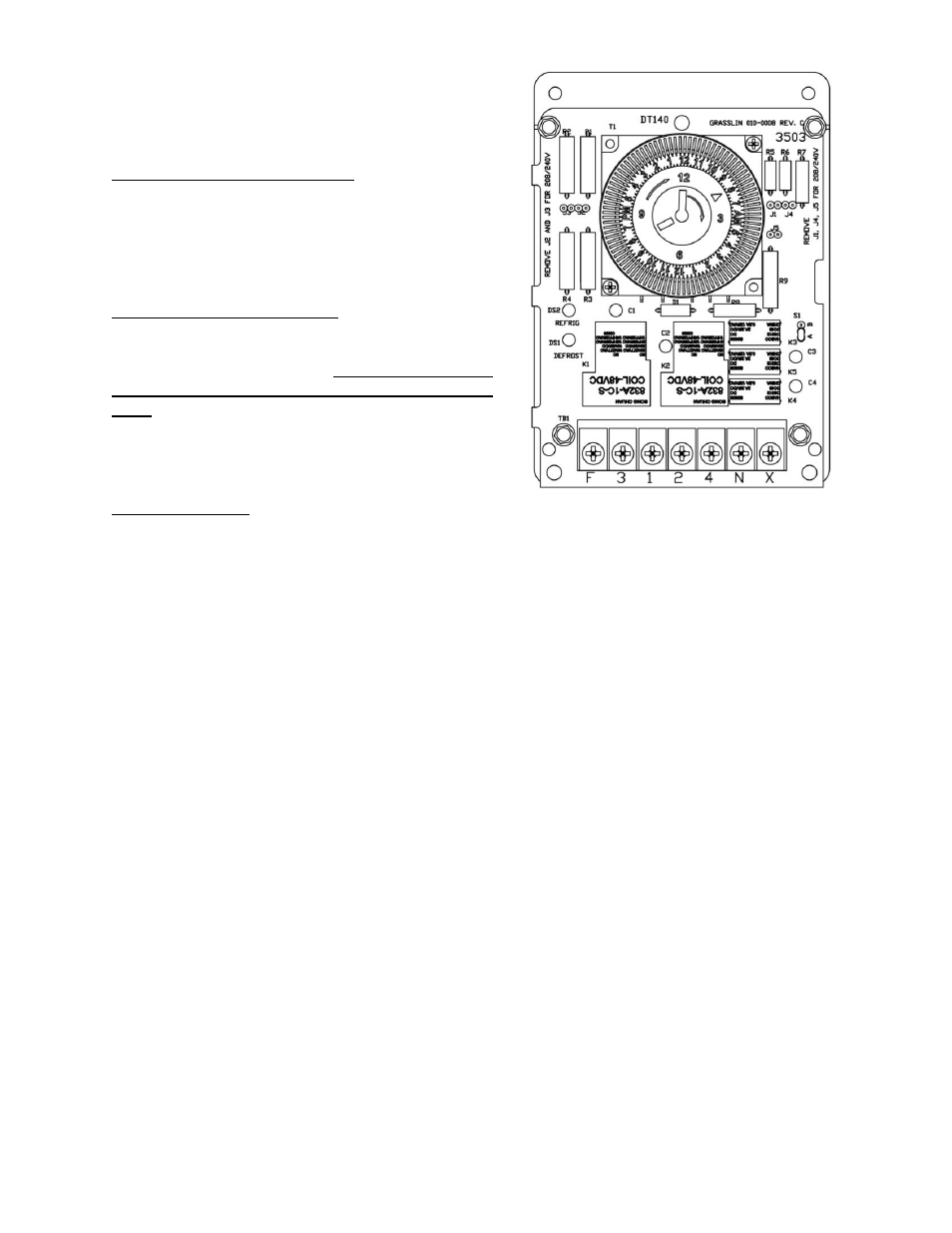

DEFROST TIME SWITCH

1. Setting the correct time of day: Simply rotate the

minute hand clockwise until the correct time of

day on the outer dial is aligned with the triangle

marker on the inner dial. In referring to the

illustration, the correct time of day shown is 8:00

a.m.

2. Number of defrosts per day: The time switch is

factory set to provide four defrosts per day. If

more defrosts are required, move additional white

tabs at the desired time. No more than two

consecutive tabs should be set at any one

time. Each white tab constitutes 15 minutes of

defrost time. If the four defrost periods provided

are more than necessary, push white tabs back

toward the center of the dial.

3. Fail-Safe feature: The fail-safe of the timer is

factory set at 30 minutes. The function of this device is to terminate the defrost cycle and revert

back to the cooling cycle if a system malfunction occurs during defrost. No adjustment of this

device should ever be necessary. Lengthening the fail-safe time will not lengthen the

defrost cycle.

Note: The defrost times are factory set at 10:00 a.m., 4:00 p.m., 10:00 p.m., and 4:00 a.m. This

setting will provide adequate defrosting for a normal installation.

WARNING: The fail-safe feature is a safety mechanism and should never be used to control the

length of defrost. This feature is provided to protect the contents of the freezer from damage should

the system fail to revert to the cooling cycle because of mechanical difficulties.

PRE-CHARGED REFRIGERANT LINES (If applicable)

By employing self-sealing refrigeration couplings, the condensing unit, the unit cooler, and the

connecting tubing are separately pre-charged with refrigerant and leak tested at the factory before

shipment. Follow these simple steps to install the connecting tubing:

1. Carefully uncoil the suction line. This line is covered with a continuous length of sponge rubber

insulating tubing.

2. Carefully uncoil the liquid line. This is the smaller diameter, bare copper tube.

3. Before making any connections, determine the routing of both lines and carefully hand bend

them to suit the situation. Keep the bend radius rather large to prevent kinking of the tubing. It is

a general practice to route the suction and liquid line parallel and close together in the

installation.

4. The pre-charged lines will have a 90° bend on one end. If the pre-charged lines are to exit

through the walk-in wall, the 90° end of the lines will be connected to the condensing unit. If the

pre-charged lines are to exit through the ceiling of the walk-in, the 90° end of the lines will be

connected to the unit cooler.