Nor-Lake Refrigeration Systems User Manual

Page 13

09/14 Rev. E 101628

13

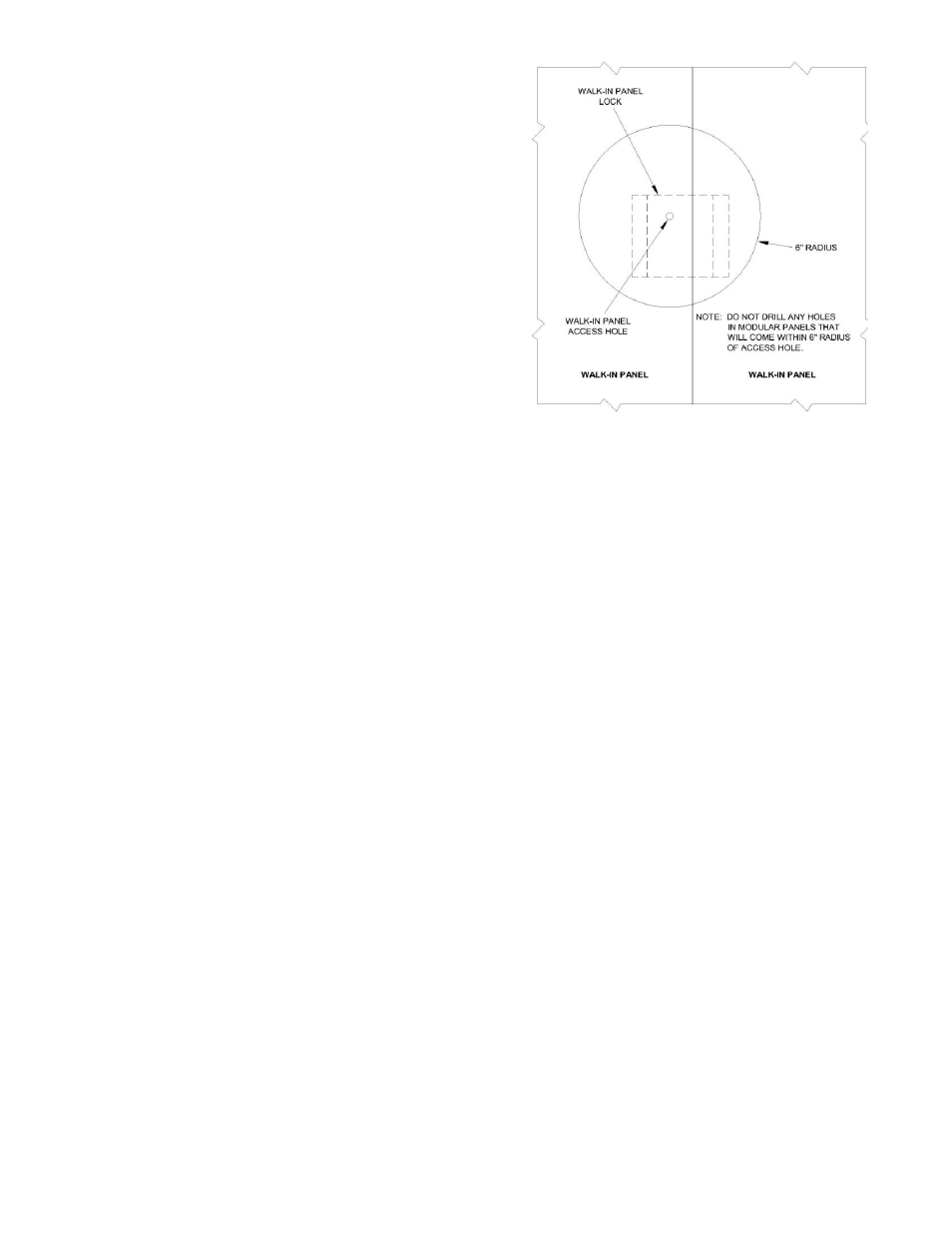

5. Locate the tubing entrance holes. Center

punch the locations. Using the proper size

hole saw, cut tubing holes straight in, not at an

angle. Two-inch diameter holes, one for the

suction line and one for the liquid line are

sufficient for coupling clearance. Caution:

Tubing entrance holes must be positioned to

clear any panel section joint, panel metal

seam, and should not fall within a six-inch

radius from the center of any panel lock

access hole. See drawing.

6. Remove the dust caps and plugs from the

couplings and inspect them to make sure the

synthetic seals are intact.

7. Using a clean cloth, wipe the coupling seals

and threaded surfaces to prevent any dirt or

foreign material from getting into the system.

8. Lubricate the synthetic seal in the male half of

the couplings with refrigeration oil and thread

the two coupling halves together BY HAND to insure proper mating of the threads. Note: Make

certain that the insulated suction line is connected to the coupling half marked “Suction Line”

and that the bare tube liquid line is connected to the coupling half mar

ked “Liquid Line”.

9.

Using the proper size wrench on the union nut, tighten until the coupling bodies “bottom”, or until

a definite resistance is felt. Tighten an additional 1/6 to 1/4 turn. This final turn is necessary to

insure that the knife-edge metal seal bites into the brass seat of the coupling halves, forming a

leak-proof joint. Note: Always use two wrenches on the coupling body hex nut and on the union

to prevent twisting of the tube while you are tightening.

10. All valves are shipped open and ready for operation. Remember that the refrigeration couplings

on this system are self-sealing and, if the need ever arises, the couplings may be disconnected

without any loss of refrigerant.

11.

It is the installing contractor’s responsibility to ensure that the quick-connect refrigerant

couplings are properly mated, tight, and leak free.

Note: All wall penetrations must be sealed. During installation the ends of the suction line insulation

must be taped off and sealed. After the pre-charged lines are installed, the suction line insulation

must be pulled over the quick connects, taped off, and sealed to prevent condensation build up.

CONDENSATE DRAIN LINE

All condensate water from an evaporator must be disposed of properly and not allowed to

accumulate in the unit cooler drain pan or elsewhere causing a safety hazard. Condensate water

must never be drained onto the cooler or freezer floor, or onto adjacent room floors or walkways.

Drain properly to prevent personal injury.

a. All condensate drain plumbing must be installed in accordance with local codes. Caution: The

drain line hole must be positioned to clear any panel section joint, panel metal seam, and should

not fall within a six-inch radius from the center of any panel lock access hole. See drawing

above.

b. Drain lines must be copper tubing for freezer rooms. For cooler rooms, if code permits, the lines

may be PVC.

c. Drain lines must not be smaller than the unit cooler drain connection.

d. The length of drain lines within the refrigerated space must be kept as short as possible before

exiting the room.

e. For proper drainage, drain lines must be pitched downward a minimum of four inches per foot in

freezer rooms, and a minimum of one inch per foot in cooler rooms.