Nor-Lake Refrigeration Systems User Manual

Page 17

09/14 Rev. E 101628

17

Example: R-404A system with 1170 equivalent feet of 1/2 inch tubing in the condenser.

(1170 x 0.93)/100 = 10.9 pounds

TABLE 4

Equivalent Length

Refrigerant per 100 Feet

Tubing

Size

for Each

of Tubing

Return Bend

Pounds @-20°F

Inches

Feet

R-404A

3/8

.20

.050

1/2

.25

.093

5/8

.30

.149

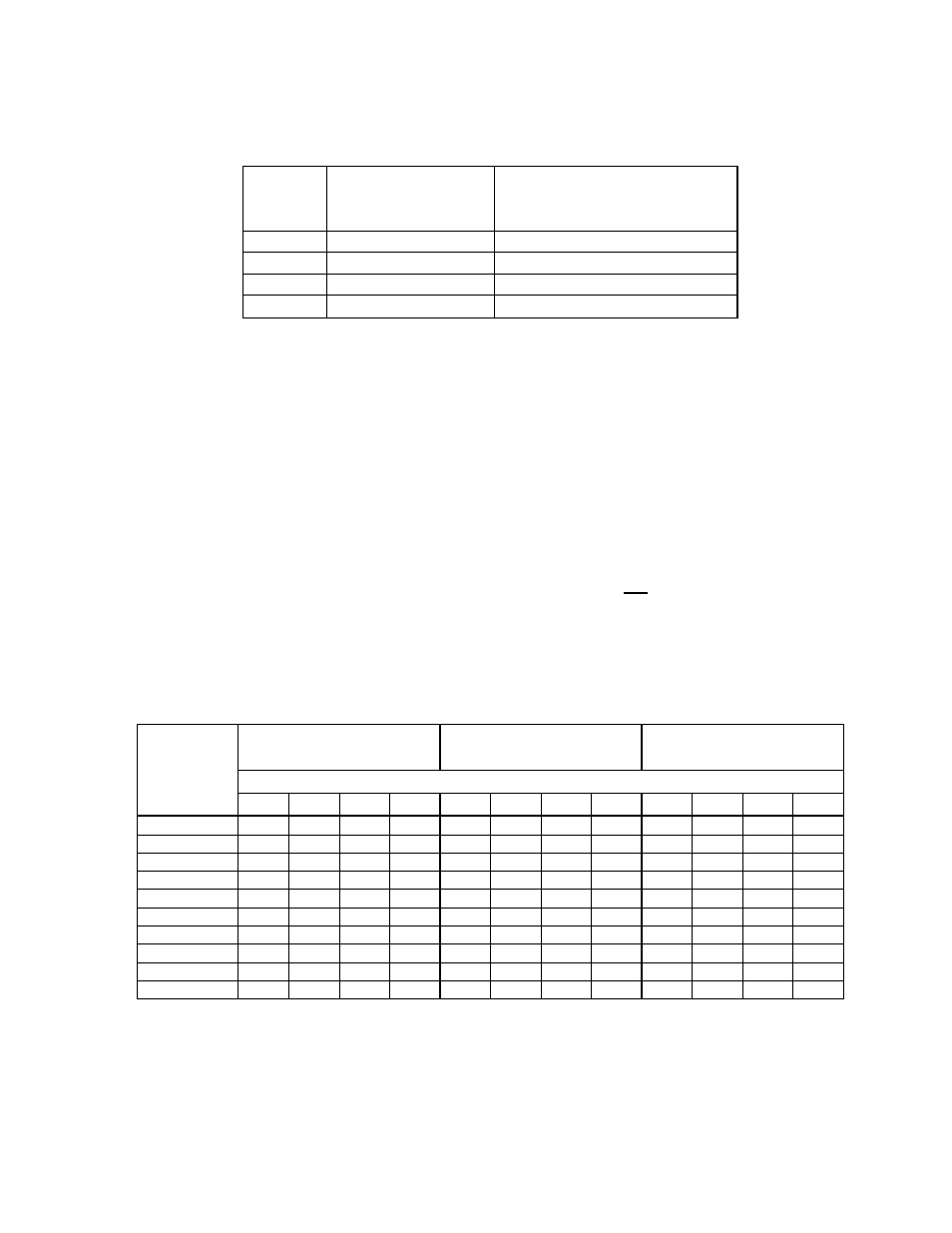

The amount of refrigerant calculated using Table 4 must be corrected since the condenser

might be already partially flooded, especially if charging is being done at low ambient

temperatures. Table 5 provides information on the percentage of the condenser to be flooded at

various ambient temperatures for high, medium, and low suction condensing units. To

determine the extra charge, determine the difference in percentage between the charging

ambient temperature and the minimum winter ambient temperature and multiply the figure by

the pounds of refrigerant calculated above.

Example: High Suction Condensing Unit, 40° Evaporating Temperature

-20°F Minimum Winter Ambient

79

50°F Charging Ambient

-40

39

10.9 pounds x.39 = 4.3 pounds of extra charge

TABLE 5

Condenser

Low Suction

Medium Suction

High Suction

Ambient

Condensing Units

Condensing Units

Condensing Units

Temperature

Evaporating Temperature - °F

°F

-35°

-25°

-15°

-5°

0°

10°

20°

30°

35°

40°

45°

50°

80°

27

15

0

0

0

0

0

0

0

0

0

0

70°

62

49

35

15

40

24

0

0

0

0

0

0

60°

76

65

56

45

60

47

33

17

26

20

10

4

50°

83

75

68

60

70

60

50

38

45

40

33

28

40°

86

80

74

68

76

68

60

50

56

52

46

42

30°

88

84

79

74

80

73

66

59

64

60

55

51

20°

90

86

82

78

83

77

72

65

69

66

62

59

0°

92

89

86

82

87

83

78

73

76

73

70

68

-20°

94

91

88

86

91

87

82

77

80

79

76

73

-40°

97

94

92

90

94

89

84

79

83

81

79

77

4. After the system has stabilized, check for excessive liquid flood back to the compressor. If

flooding occurs, adjust the expansion valve as required to correct the situation.

5. Do not leave the system unattended until it reaches normal operating conditions, and do not

allow product to be stored in the cold room until a complete system operational check is

completed.