A178, Assembly & installation instructions – Hubbardton Forge 137530 User Manual

Page 3

Assembly & Installation Instructions

A178

Ellipse Circular Adjustable Pendant 13-7530

Page 3 of 4

Hand-Forged,

Vermont-Made Lighting and Accessories

P.O. Box 827, 154 Route 30 South, Castleton, Vermont 05735

21364 Rev A

To Install to Ceiling

(Figures 4, 5 & 6)

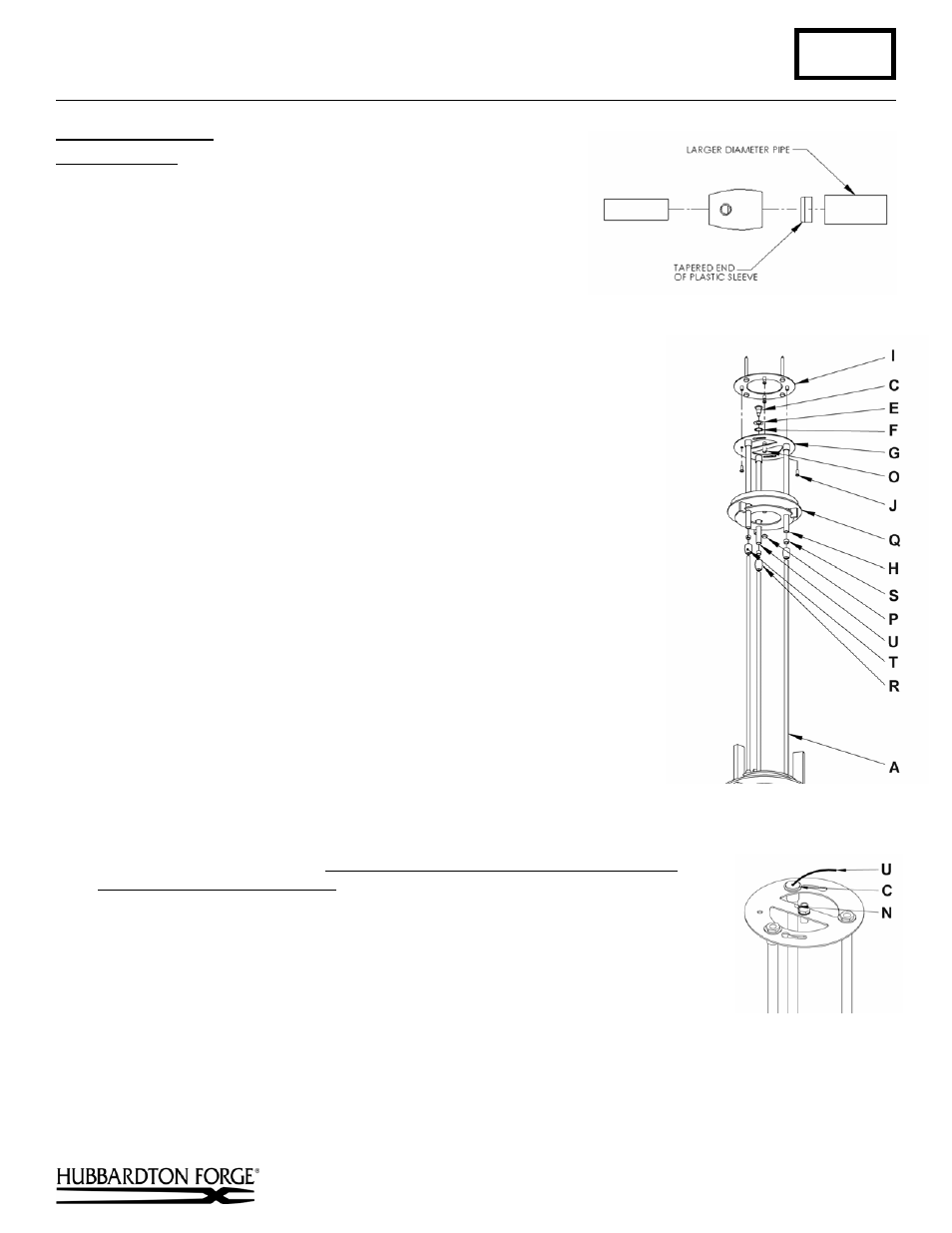

Component Parts

A Fixture Pipe (3)

C Cable

Gripper

E Flat

Washer

F Lock

Washer

G Support

Ring

H Canopy

Pipe

I Crossbar

J 10-32

Screw

(4)

N Ground

Wire

O Threaded

Nipple

P Threaded

Button

Q Canopy

R Clutch

(3)

S Plastic Clutch Sleeve (3)

T Set Screw (2)

U Cable

Caution: Be sure power is off at the main breaker box prior to installation.

1. Place canopy (Q) over canopy pipes (H).

2. Reinstall clutch sleeve (S) and clutch (R) onto canopy pipes (H).

3. Remove cable gripper (C) from support ring along with flat washer (E) and

lock washer (F). Set aside for later use.

4. Thread wires and support cable (U) from the fixture pipe (A) through the

canopy pipe (H) and out of top side of support ring (G). Make sure the cable

(U) is aligned with the hole the cable gripper (C) will be installed in.

Note:

Cable and wires are in separate pipes.

5. Pull the cable (U) through the lock washer (F), flat washer (E) and cable

gripper (C).

6. Apply a drop of the supplied thread locking compound to the external threads

of the cable gripper (C). Slip flat washer (E) and lock washer (F) over cable

gripper (C). Slip cable gripper (C) through support ring (G) and thread into

canopy pipe (H).

7. Unscrew the clutch (R) from the canopy pipe (H); slide it across the wires

and onto the fixture pipe (A). Follow this with the plastic clutch sleeve (S),

oriented so the tapered end of the clutch sleeve nests in the clutch

(Figure 4).

8. Slide the canopy pipe (H) as far as necessary to give you the total length of

the fixture which you desire. Be careful not to scratch the pipe surfaces and

to pull excess wire up through the canopy pipe (H). There must be a minimum

1-1/2" of inner pipe inside the outer pipe. Hand-tighten the clutch to

temporarily hold this adjustment. The clutch is not securely fastened at this point; do

not depend on it to hold the fixture.

Important: To ensure full connection strength, be sure the tapered end of the plastic

clutch sleeve is oriented toward the clutch when assembled and securely tighten set

screw (Figure 4).

9. Pull cable (U) through cable gripper (C) until tight. Remove excess cable

(Figure 6).

10. Raise fixture to ceiling aligning two 10-32 screws (J) installed in the cross bar

previously with the keyed slots in the support ring (G). Turn fixture until all four holes

in the support ring (G) align with the threads in crossbar (I). Tighten the screws.

(continued)

(Figure 5)

(Figure 4)

(Figure 6)