Printing quality problems – Samsung ML-6512ND-XAA User Manual

Page 92

Troubleshooting_ 92

Printing quality problems

If the inside of the machine is dirty or paper has been loaded improperly,

there might be a reduction in print quality. See the table below to clear the

problem.

The print quality

of photos is not

good. Images are

not clear.

The resolution of

the photo is very

low.

Reduce the photo size. If

you increase the photo size

in the software application,

the resolution will be

reduced.

Before printing,

the machine

emits vapor near

the output tray.

Using damp paper

can cause vapor

during printing.

This is not a problem. Just

keep printing.

The machine

does not print

special- sized

paper, such as

billing paper.

Paper size and

paper size setting

do not match.

Set the correct paper size in

the Paper tab in the Print-

ing Preferences (See

CONDITION

SUGGESTED SOLUTIONS

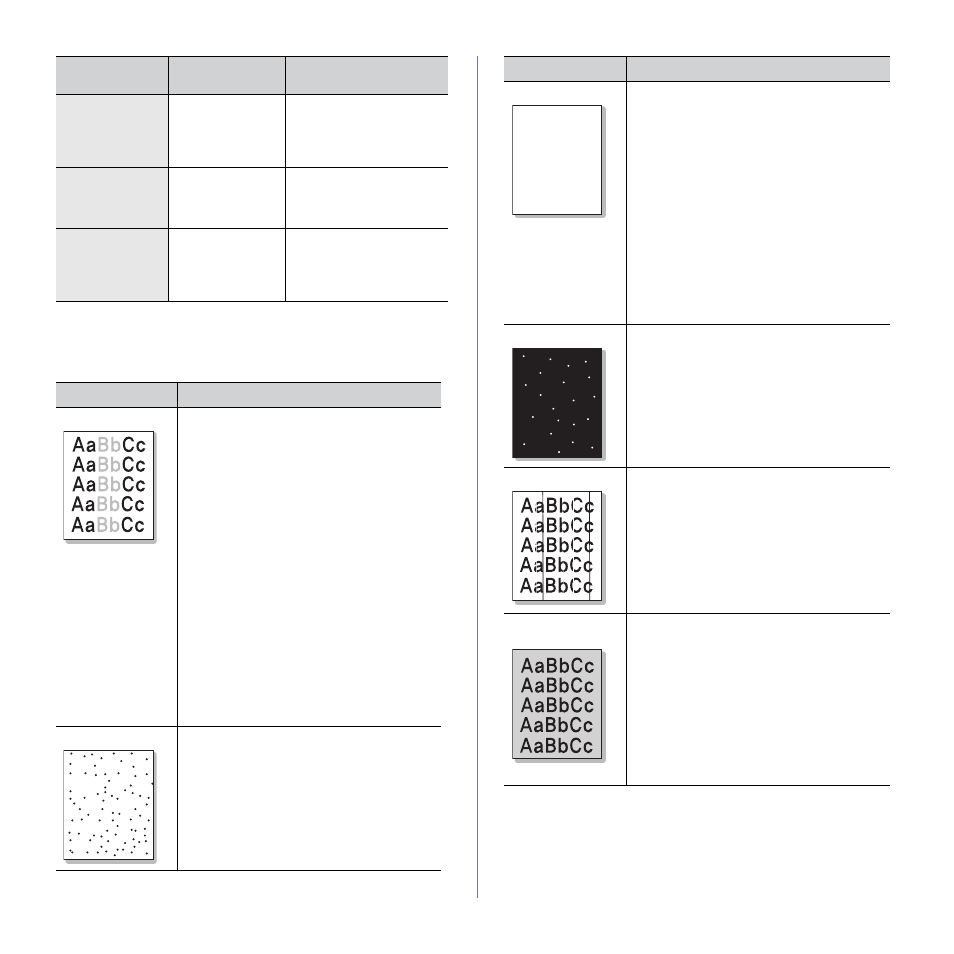

Light or faded print

•

If a vertical white streak or faded area

appears on the page, the toner supply is low

or the imaging unit is worn. You may be able

to temporarily extend the toner cartridge life

(See"Redistributing toner" on page 76). If this

does not improve the print quality, install a

new toner cartridge or imaging unit.

•

The paper may not meet paper specifications;

for example, the paper may be too moist or

rough (See "Print media specifications" on

•

If the entire page is light, the print resolution

setting is too low or the toner save mode is

on. Adjust the print resolution and turn the

toner save mode off. See the help screen of

the printer driver.

•

A combination of faded or smeared defects

may indicate that the imaging unit needs

cleaning (See "Cleaning the inside" on

•

The surface of the LSU part inside the

machine may be dirty (See "Cleaning the

Toner specks

A a

B b

C c

A a

B b

C c

A a

B b

C c

A a

B b

C c

A a

B b

C c

•

The paper may not meet specifications; for

example, the paper may be too moist or rough

(See "Print media specifications" on

•

The transfer roller may be dirty. Clean the

inside of your machine. Contact a service rep-

resentative.

•

The paper path may need cleaning. Contact a

service representative.

CONDITION

POSSIBLE

CAUSE

SUGGESTED SOLU-

TIONS

Dropouts

A a B b C

A a B b C

A a B b C

A a B b C

A a B b C

If faded areas, generally rounded, occur ran-

domly on the page:

•

A single sheet of paper may be defective.

Try reprinting the job.

•

The moisture content of the paper is uneven

or the paper has moist spots on its surface.

Try a different brand of paper (See "Print

media specifications" on page 110).

•

The paper lot is bad. The manufacturing pro-

cesses can cause some areas to reject

toner. Try a different kind or brand of paper.

•

Change the printer option and try again. Go

to Printing Preferences, click Paper tab,

and set type to Thick (See "Opening printing

•

If these steps do not correct the problem,

contact a service representative.

White Spots

If white spots appear on the page:

•

The paper is too rough and a lot of dirt from a

paper falls to the inner devices within the

machine, so the transfer roller may be dirty.

Clean the inside of your machine (See

"Cleaning the inside" on page 73).

•

The paper path may need cleaning (See

"Cleaning the inside" on page 73).

Vertical lines

If black vertical streaks appear on the page:

•

The surface (drum part) of the imaging unit

inside the machine has probably been

scratched. Remove the imaging unit and

install a new one (See "Replacing the imag-

If white vertical streaks appear on the page:

•

The surface of the LSU part inside the

machine may be dirty (See "Cleaning the

Color or Black

background

If the amount of background shading becomes

unacceptable:

•

Change to a lighter weight paper (See "Print

media specifications" on page 110).

•

Check the environmental conditions: very

dry conditions or a high level of humidity

(higher than 80% RH) can increase the

amount of background shading.

•

Remove the old imaging unit and, install a

new one (See "Replacing the imaging unit"

on page 99). If this problem persists, contact

a service representative.

CONDITION

SUGGESTED SOLUTIONS