2 gas analyzer wicks, Gas analyzer wicks, 1. rain wick replacement parts – Campbell Scientific IRGASON Integrated CO2/H2O Open-Path Gas Analyzer and 3D Sonic Anemometer User Manual

Page 37

IRGASON

®

Integrated CO

2

/H

2

O Open-Path Gas Analyzer and 3D Sonic Anemometer

9.2.2 Gas Analyzer Wicks

IRGASON gas analyzer windows are polished and slanted at an angle to

prevent water from collecting on their surfaces. However, due to increased

surface tension at the interface with the snout, water can pool at the edges and

partially block the optical path and attenuate the signal. To minimize the

occurrence of such events and the resulting data loss, consider using wicks.

The weave of the wick fabric promotes capillary action that wicks the water

away from the edge of the windows. The seam and the straight edge of the

wicks are permeated with a rubberized compound to prevent them from

shifting during operation.

Proper installation of the wicks is critical. They should not block or encroach

on the optical path. Before installation, record signal strengths for both H

2

O

and CO

2

. Following installation, these values should be unchanged.

Wicks are available as listed in TABLE 9-1.

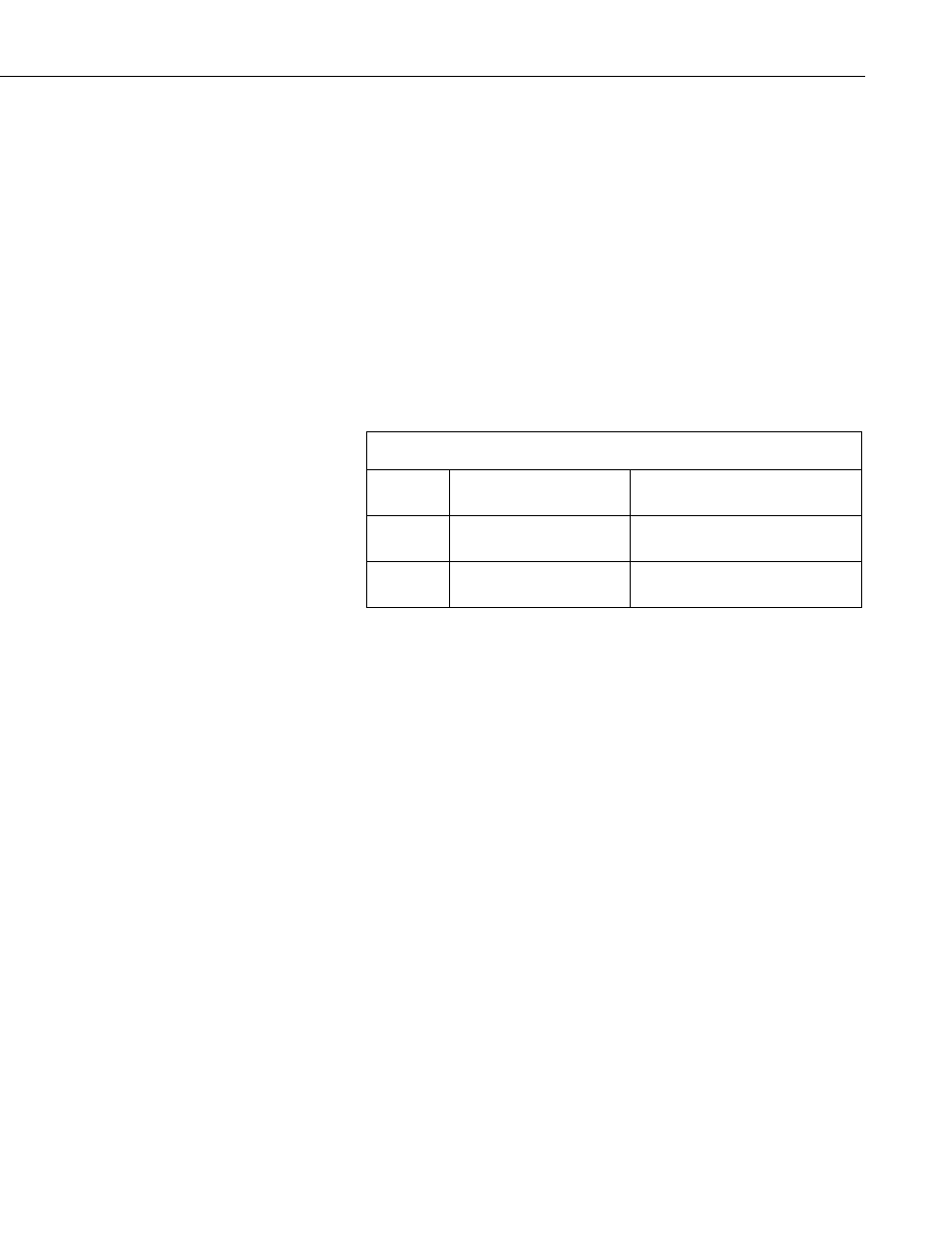

TABLE 9-1. Rain Wick Replacement Parts

Wick

Campbell Scientific, Inc.

Part Number

Campbell Scientific Description

Bottom

Wick

28652

FAB EC150/IRGASON RAIN

WICK BOTTOM

Top Wick 28653

FAB EC150/IRGASON RAIN

WICK TOP

The top wick has a short seam which has to be aligned with the short side of

the top snout. The angled edge of the wick must closely follow the edge of the

window without encroaching on the optical path (see FIGURE 9-3, Proper

location of the sonic top wick and bottom wick). The bottom wick is installed

in a similar manner, except the long seam should be aligned with the long side

of the bottom snout. Once in place, the wicks should fit snuggly over the

cylindrical part of the snout without any creases or wrinkles.

The wicks are constructed with a UV-resistant fabric and should function over

long time periods. Nevertheless, they should be inspected periodically. Check

for contamination from dust, pollen, pitch or other debris. If needed, wash

them in warm water with mild detergent or replace them. When performing

the zero-and-span procedure, the wicks should be removed before installing the

zero-and-span shroud.

Remove the wicks during the winter. The wicks will accumulate snow or

freezing rain, resulting in blockage of the optical path. Besides the wicks,

controlling the heaters in the snouts is another method the user may consider in

preventing data loss during precipitation and condensation events. The heaters

can be controlled statically using the

Setup window in ECMon or dynamically

using a datalogger (see Section 10.2, EC100Configure() Instruction, for more

details).

27