Campbell Scientific AP200 CO2/H2O Atmospheric Profile System User Manual

Page 97

Appendix F. Valve Sequence Timing

Example 2:

LEVELS_USED = 5, STARTsequence set to True at 9:00:20.

As shown in TABLE F-1, the cycle time for 5 levels is 90 s. To synchronize

with the real-time clock, the sequence must start at multiples of 90 s, (for

example, 9:00:00, 9:01:30, 9:03:00, etc.) Valve 1 will be selected as soon as

STARTsequence is set = True (9:00:20), but the sequence will not actually

start until 9:01:30. Data will be included in the average for level 1 from

9:01:42 to 9:01:48, when the valve will switch to level 2. Data will be

included in the average for level 2 from 9:02:00 to 9:02:06, when the valve will

switch to level 3, and so on.

Calibration Sequence

The calibration (zero/span) sequence timing depends on the number of levels

used and also on whether the zero/span is merely to be checked or if the IRGA

is to set its internal zero and span coefficients. In either case the zero/span

sequence cycle time is chosen to replace an integer multiple of profile

sequences. This allows a seamless transition back and forth between the

profile sequence and the calibration sequence.

The zero/span behavior is determined by two of the system configuration

variables as shown in TABLE F-2.

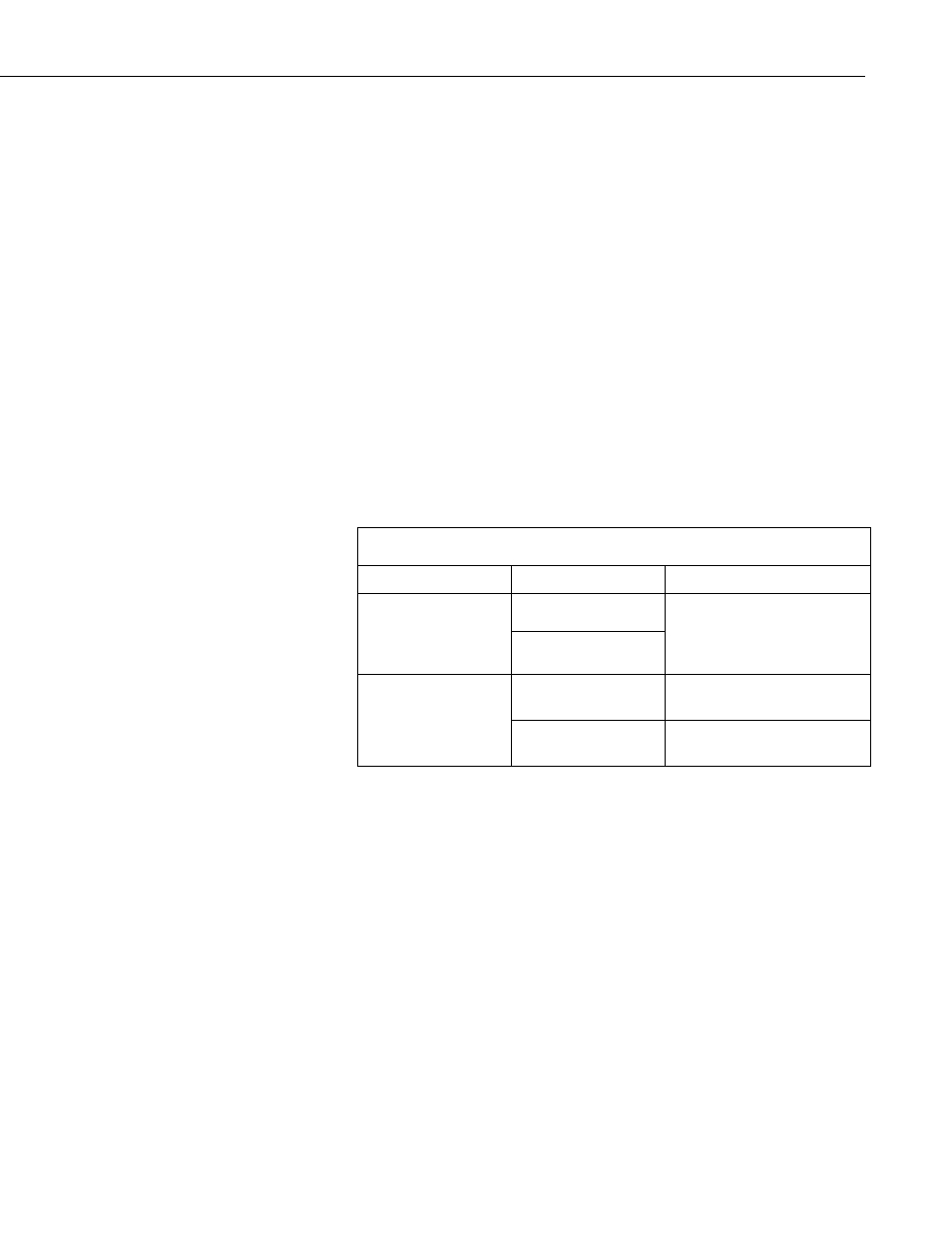

TABLE F-2. System Configuration Variables of Zero/Span

MEASURE_TANKS AUTO_ZEROSPAN

False

False

Do not measure cylinders. Run

profile sequence all the time

True

True

False

Measure cylinders but do not

set the zero or span

True

Measure cylinders and set the

zero and span

Without Setting Zero and Span

If the AP200 is configured with

MEASURE_TANKS = True and

AUTO_ZEROSPAN = False, it will check the zero and CO

2

span, but it will

not command the IRGA to set them. This section gives timing details for this

case. The AP200 zero/span sequence will:

•

Select inlet 10 (CO

2

Span), omit at least 20 s for equilibration, and

include 10 s in the average.

•

Select inlet 9 (Zero), omit at least 30 s for equilibration, and include

10 s in the average.

•

Select inlet 1 for at least 10 s. This allows the humidity in the tubing

and IRGA to equilibrate before restarting the profile sequence.

As shown in TABLE F-3, this minimum timing adds up to 80 s for the

zero/span sequence. The time for one or more of the steps is increased as

needed to equal the profile sequence cycle time (or a multiple of the cycle

F-3