22. pump module of ap200 system – Campbell Scientific AP200 CO2/H2O Atmospheric Profile System User Manual

Page 29

AP200 CO

2

/H

2

O Atmospheric Profile System

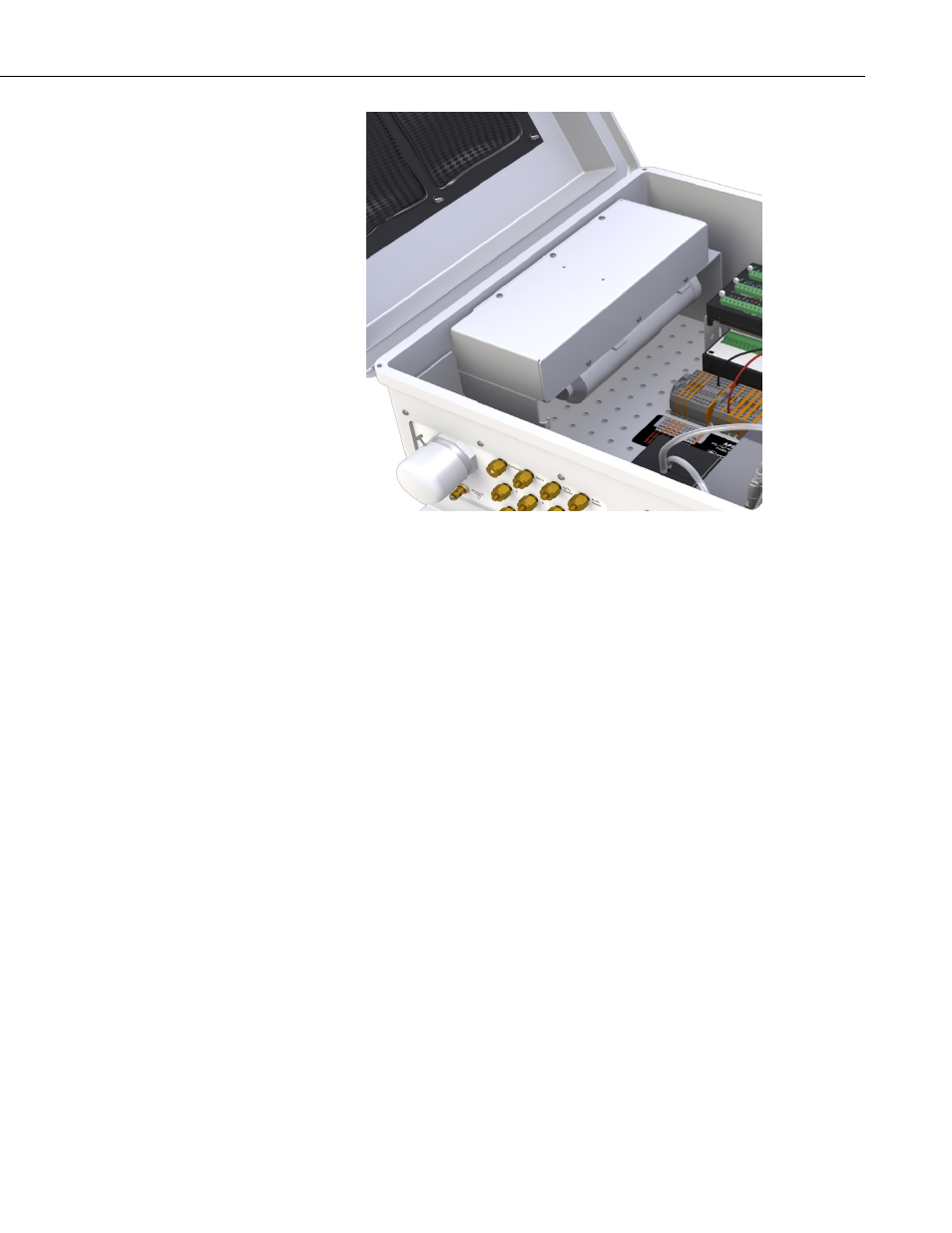

FIGURE 4-22. Pump module of AP200 system

The AP200 pump module pulls air through the system and exhausts it through

the

Exhaust fitting on the bottom of the system enclosure. It uses a small

double-head diaphragm pump with a brushless DC motor. This pump includes

a speed control input and a tachometer to measure the actual pumping speed. It

is mounted in an insulated, temperature-controlled box inside the AP200

system enclosure. The following sections describe the monitored pump

operating parameters.

Pump Inlet Pressure: The measured inlet pressure of the pump is reported in

public variable

pump_press. The AP200 sets the value of public variable

pump_control to a value between 0 (off) and 1 (full speed) to adjust the

pump’s speed as needed to match the measured pressure to the setpoint

pressure

PUMP_P_SETPT. PUMP_P_SETPT is a system configuration

variable (see Section 5.4.1, System Configuration Variables). This pressure

setting affects the power required for the pump (lower pressure requires more

power), the possibility of water condensing in the tubing (lower pressure helps

to prevent condensation), and the flow rate (lower pressure will increase the

flow rate). The pump can achieve a maximum of approximately 60 kPa

pressure drop from ambient pressure at zero flow. The recommended setting

for the pump is 35 kPa below ambient pressure.

The pump module includes two buffer volumes to dampen the pressure

fluctuations from the pump. The sample flow from the IRGA flows through

these volumes in series on the way to the pump. The bypass flow (from non-

selected inlets) connects directly to the pump.

Pump Speed: The measured pumping speed is reported in public variable

pump_speed. This is the rotational speed of the pump, given in Hz. The

pumping speed will typically be 25 Hz to 40 Hz. The actual value is not

critical, however, as long as the pressure can be maintained at the setpoint.

17