5 zero/span flow, Zero/span flow, 1. irga settings – Campbell Scientific AP200 CO2/H2O Atmospheric Profile System User Manual

Page 64: 2. irga outputs

AP200 CO

2

/H

2

O Atmospheric Profile System

message_log output table when the configuration command is sent and when

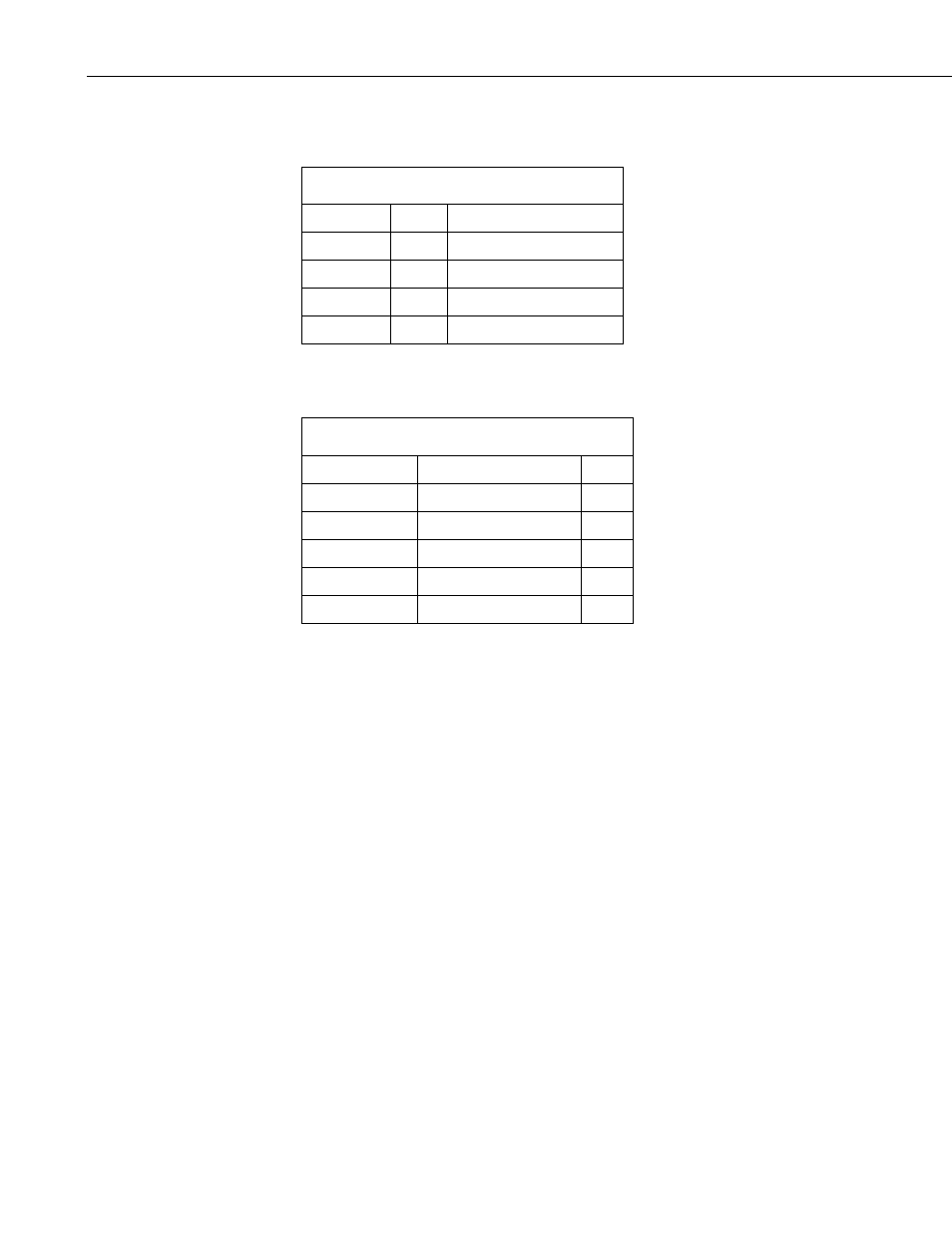

the settings are acknowledged. The IRGA settings are given in TABLE 7-1.

TABLE 7-1. IRGA Settings

Setting

Value Notes

OUTRATE 0.5

Output data every 0.5 s

HEATER

TRUE Turn heater on

PCOMP

TRUE Pressure compensation on

FILTER

0

No filter

The outputs from the IRGA are shown in TABLE 7-2 and include:

TABLE 7-2. IRGA Outputs

Public variable Description

Units

CO

2

CO

2

concentration

ppm

H

2

O

H

2

O concentration

ppt

cell_tmpr

Sample cell temperature °C

cell_press

Sample cell pressure

kPa

Td_cell

H

2

O dewpoint

°C

7.5 Zero/Span Flow

The flow for the zero and CO

2

span cylinders is affected by the pressure

regulator performance. Pressure regulators designed for a low delivery

pressure will generally perform better and should be used where possible. To

adjust these regulators, start with them set for 0-psig outlet pressure. Select the

corresponding inlet and observe the sample flow. Adjust the regulator outlet

pressure to give approximately the same sample flow as for the profile inlets

(within 10%).

Most pressure regulators will regulate the pressure only when there is flow

through them. When the flow stops (because the AP200 selects some other

valve), the pressure will rise above the setting. It will remain high until the

zero or CO

2

span valve is again selected, and the flow can resume. The flow

will be higher than normal (because pressure is higher than normal) until the

excess pressure is bled from the regulator and tube.

Most pressure regulators will also be affected by ambient temperature. If the

zero or CO

2

span sample flow varies excessively as the ambient temperature

changes, or if the pressure rise at shut-off is excessive, consider using a

different regulator.

The amount of zero or CO

2

span gas consumed depends on the details of the

application. The following example shows how to estimate the expected

consumption.

52