Pid control, Time proportional pid control, Linear pid control – Red Lion PAX2C User Manual

Page 49: Manual control mode, Mode transfer, Automatic control mode, Proportional band, Integral time

49

PID CONTROL

In PID Control, the controller processes the input and then calculates a

control output power value by use of a specialized Proportional Band,

IntegralTime, and Derivative Time control algorithm. The system is controlled

with the new output power value to keep the process at the setpoint. The Control

Action for PID Control can be set to reverse for heating (output on when below

the setpoint) or direct for cooling (output on when above the setpoint)

applications.For heat and cool systems, the heat and cool outputs are both used.

The PID parameters can be established by using Auto-Tune, or they can be

Manually tuned to the process.

TIME PROPORTIONAL PID CONTROL

In Time Proportional applications, the output power is converted into output

On time using the Cycle Time. For example, with a four second cycle time and

75% power, the output will be on for three seconds (4 × 0.75) and off for

one second.

The cycle time should be no greater than 1/10 of the natural period of

oscillation for the process. The natural period is the time it takes for one

complete oscillation when the process is in a continuously oscillating state.

LINEAR PID CONTROL

In Linear PID Control applications, the Analog Output Assignment ANAS is set

to % Output Power, OP. The Analog Low Scaling, ANLO , is set to 0.0 and the

Analog High Scaling, ANHI, is set to 100.0. The Analog Output will then be

proportional to the PID calculated % output power for Heat or Cooling per the

Control Action OPAC. For example, with 0 VDC to 10 VDC (scaled 0 to 100%)

and 75% power, the analog output will be 7.5 VDC.

MANUAL CONTROL MODE

In Manual Control Mode, the controller operates as an open loop system

(does not use the setpoint or process feedback). The user adjusts the percentage

of power through the % Power display to control the output power. Manual

operation provides 0 to 100% power to the HEAt output and -100 to 0% power

to the COOL output. The Low and High Output Power limits are ignored when the

controller is in Manual.

MODE TRANSFER

When transferring the controller mode between Automatic and Manual, the

controlling outputs remain constant, exercising true “bumpless” transfer. When

transferring from Manual to Automatic, the power initially remains steady, but

Integral Action corrects (if necessary) the closed loop power demand at a rate

proportional to the Integral Time.

AUTOMATIC CONTROL MODE

In Automatic Control Mode, the percentage of output power is automatically

determined by PID or On/Off calculations based on the setpoint and process

feedback.

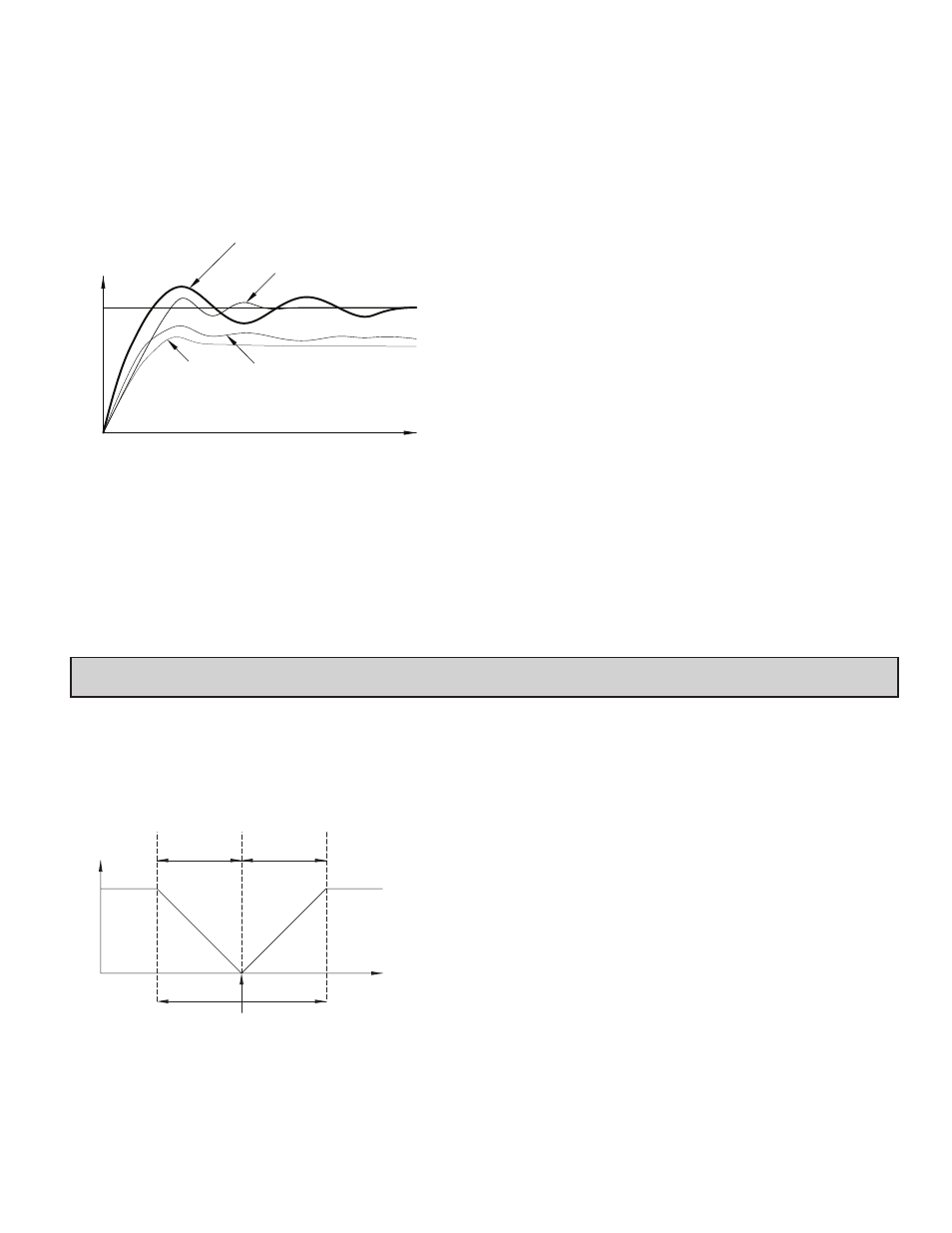

TYPICAL PID RESPONSE CURVE

pid COnTrOl

PROPORTIONAL BAND

Proportional band is defined as the “band” of temperature the process

changes to cause the percent output power to change from 0% to 100%. The

band may or may not be centered about the setpoint value depending upon the

steady state requirements of the process. The band is shifted by manual offset or

integral action (automatic reset) to maintain zero error. Proportional band is

expressed as percent of input sensor range.

Example: Thermocouple type T with a temperature range of 600°C is used and

is indicated in degrees Celsius with a proportional band of 5%. This yields a

band of 600°C X 5% = 30°C.

The proportional band should be set to obtain the best response to a

disturbance while minimizing overshoot. Low proportional band settings (high

gain) result in quick controller response at expense of stability and increased

overshoot. Settings that are excessively low produce continuous oscillations at

setpoint. High proportional band settings (low gain) result in a sluggish response

with long periods of process “droop”. A proportional band of 0.0% forces the

controller into ON/OFF control mode with its characteristic cycling at setpoint

(See ON/OFF Control for more information).

INTEGRAL TIME

Integral time is defined as the time, in seconds, in which the output due to

integral action alone equals the output due to proportional action with a constant

process error. As long as a constant error exists, integral action repeats the

proportional action every integral time. Integral action shifts the center point

position of the proportional band to eliminate error in the steady state. The units

of integral time are seconds per repeat.

Integral action (also known as “automatic reset”) changes the output power

to bring the process to setpoint. Integral times that are too fast (small times) do

not allow the process to respond to the new output value. This causes over

compensation and leads to an unstable process with excessive overshoot.

Integral times that are too slow (large times) cause a slow response to steady

state errors. Integral action may be disabled by setting the time to zero. If time

is set to zero, the previous integral output power value is maintained.

If integral action is disabled, manual reset is available by modifying the

output power offset (OPOF initially set to zero) to eliminate steady state errors.

This parameter appears in unprotected parameter mode when integral time is set

to zero. The controller has the feature to prevent integral action when operating

outside the proportional band. This prevents “reset wind-up”.

SETPOINT

100

0

HEATING

COOLING

TEMPERATURE

P-BAND

P-BAND

DIRECT

ACTING

REVERSE

ACTING

OUTPUT

POWER (%)

Digital

Output

Digital

Output

SP

TIME

P & I

P & I & D

P only

P & D

INPUT