Pid p, Pid ), Prop – Red Lion PAX2C User Manual

Page 33: Intt, Dert, Fltr, Opof

33

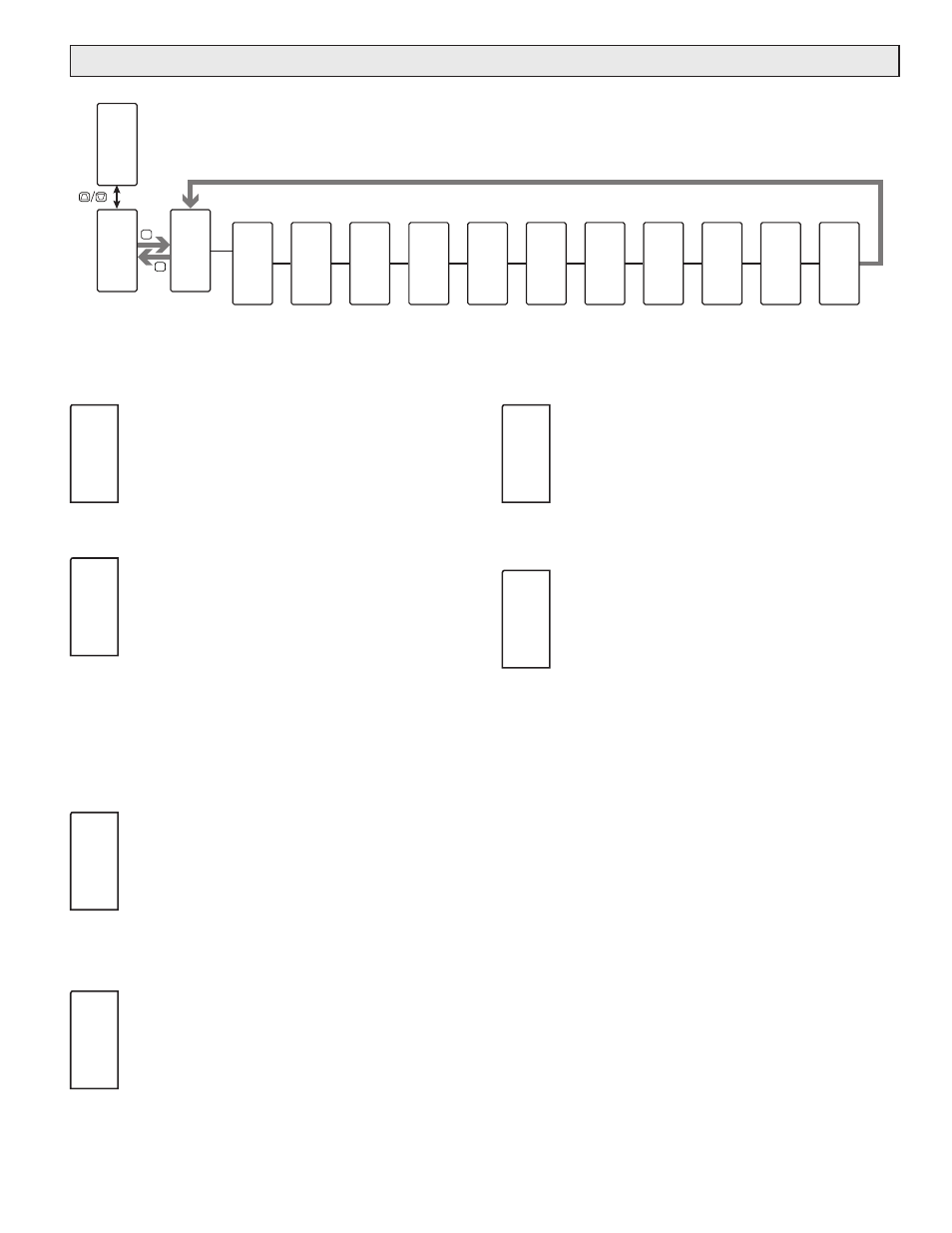

PID

Parameter

Selection

Primary

Proportional

Band Value

Primary

Integral

Time Value

F1

F2

P

D

Pro

N O

Pro

P i d

Pid

P i d

Pid

P r i

SEL

ProP

4 . 0

Pri

Intt

1 2 0

Pri

Primary

Derivative

Time Value

dErt

3 0

Pri

Primary

Power Filter

Value

FLtr

1 . 0

Pri

Primary

Output Offset

Value

OPOF

0 . 0

Pri

Alternate

Proportional

Band Value

ProP

4 . 0

ALt

Alternate

Integral

Time Value

Intt

1 2 0

ALt

Alternate

Derivative

Time Value

dErt

3 0

ALt

Alternate

Power Filter

Value

FLtr

1 . 0

ALt

Alternate

Output Offset

Value

OPOF

0 . 0

ALt

pid p

arameTers

: pid p

arameTers

(Pid)

PID PARAMETER SELECTION

Pri

ALt

Select the desired set of PID Values (Primary or Alternate) that

will be used in the PID calculation. The PID Parameter Selection

function can also be configured in the Display Parameter LOCS Menu

(Pid LOCS) or a User Input or Function Key can be assigned to the PID

Parameter Selection Function.

PRIMARY/ALTERNATE PROPORTIONAL BAND

0

to

999.9

%

The Proportional Band property, entered as a percentage of the full

input range, is the amount of input change required to vary the output

full scale. For temperature inputs, the input range is fixed per the

entered thermocouple or RTD type. For process inputs, the input

range is the difference between the Process at 0%, and Process at

100% values. The Proportional Band is adjustable from 0.0% to 999.9%, and

should be set to a value that provides the best response to a process disturbance

while minimizing overshoot. A Proportional Band of 0.0% forces the controller

into On/Off Control with its characteristic cycling at setpoint. The optimal value

may be established by invoking Auto-tune.

PRIMARY/ALTERNATE INTEGRAL TIME

0

to

65000

seconds

The Integral Time is the time in seconds that it takes the integral

action to equal the proportional action, during a constant process

error. As long as the error exists, integral action is repeated each

Integral Time. The higher the value, the slower the response. The

optimal value may be established by invoking autotune.

PRIMARY/ALTERNATE DERIVATIVE TIME

0

to

9999

seconds

The Derivative Time is the seconds per repeat that the controller

looks ahead at the ramping error to see what the proportional

contribution will be and then matches that value every Derivative

Time. As long as the ramping error exists, the derivative contribution

is repeated every derivative time. Increasing the value helps to

stabilize the response. Too high of a value, coupled with noisy signal

processes, may cause the output to fluctuate too greatly, yielding poor control.

Setting the time to zero disables derivative action. The optimal Derivative Time

may be established by invoking auto-tune.

PRIMARY/ALTERNATE POWER FILTER

0

to

60.0

seconds

The Power Filter is a time constant, entered in seconds, that

dampens the calculated output power. Increasing the value increases

the dampening effect. Generally, a Power Filter in the range of one-

twentieth to one-fiftieth of the controller’s integral time (or process

time constant) is effective. Values longer than these may cause

controller instability due to the added lag effect.

PRIMARY/ALTERNATE OUTPUT OFFSET

-100.0

to

100.0

This value effectively shifts the zero output point of the module’s

output power calculation. This feature is most commonly used in

proportional-only applications to remove steady-state error.

Pid

Pri

SEL

ProP

4.0

Intt

120

dErt

30

FLtr

1.0

OPOF

0.0