Fact ), Code, Rset – Red Lion PAX2C User Manual

Page 46: Actory, Ervice, Perations, F a c t, X.xx

46

f

aCTOry

s

erviCe

O

peraTiOns

(FACt)

RESTORE FACTORY DEFAULTS

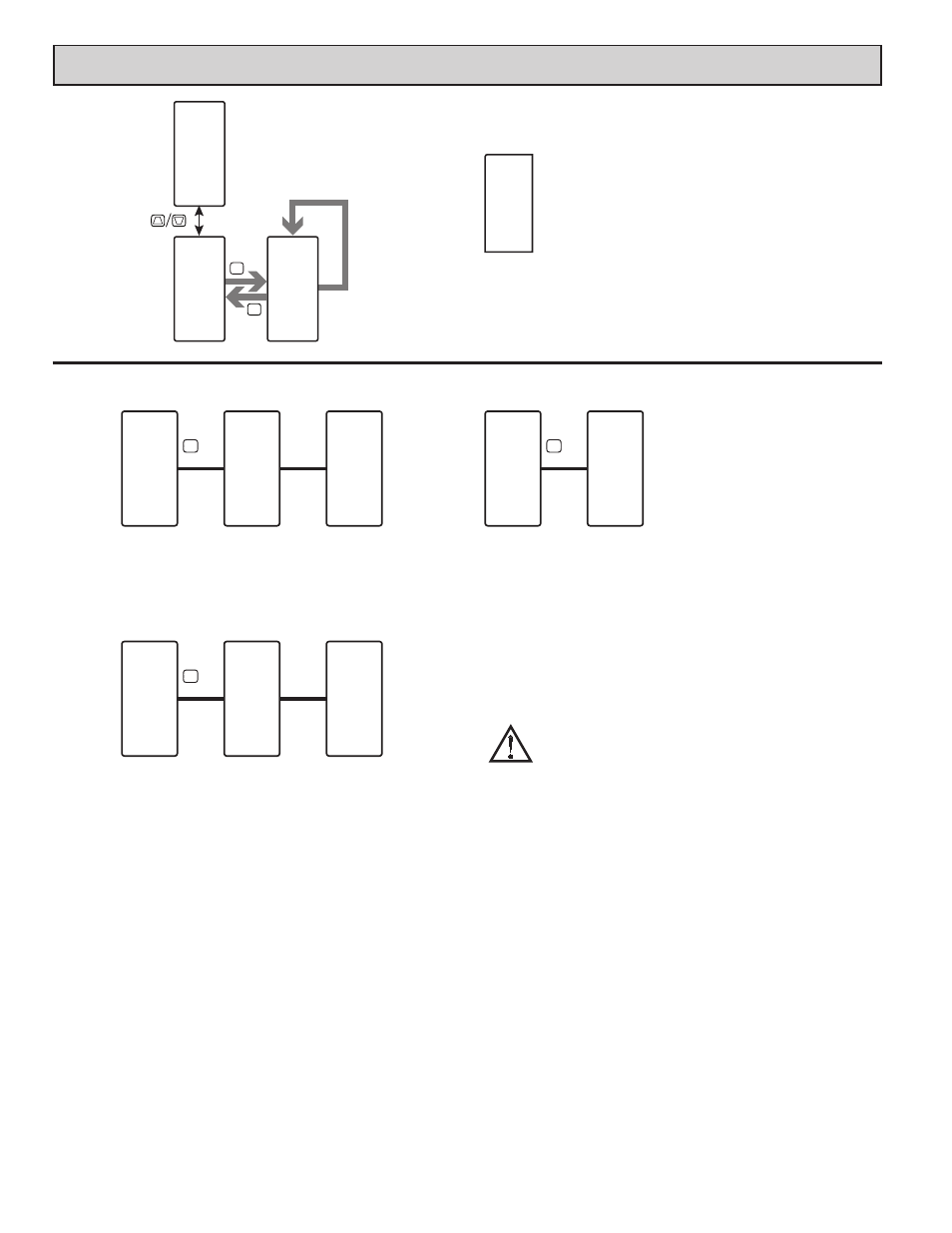

Use the ! and @ keys to display COdE 66 and press

P. The controller will

flash rSEt and then return to COdE 50. This will overwrite all user settings with

the factory settings.

MODEL AND CODE VERSION

The controller will briefly display the model (P2C) on Line 1, and the current

firmware version (UEr x.xx) on Line 2, and then return to COdE 50.

CONTROLLER CALIBRATION

NO Curr UoLt rES

tc ICE rtd AnLG

The controller has been fully calibrated at the factory. Scaling to convert the

input signal to a desired display value is performed in Input Parameters. If the

controller appears to be indicating incorrectly or inaccurately, refer to

Troubleshooting before attempting to calibrate the controller. When recalibration

is required (generally every 2 years), it should only be performed by qualified

technicians using appropriate equipment. Calibration does not change any user

programmed parameters. However, it will affect the accuracy of the input signal

and the values previously stored using the Apply (APLY) Scaling Style.

Preparation for Current, Volt, and Ohm Input Calibration

Warning: Input Calibration of this controller requires a signal source

capable of producing a signal greater than or equal to the range

being calibrated with an accuracy of 0.01% or better.

Before starting, verify that the Input Range, T/V, and Excitation Jumper is set

for the range to be calibrated. Verify that the precision signal source is connected

and ready. Allow a 30 minute warm-up period before calibrating the controller.

Selecting NO at any calibration step, will cause the unit to maintain the existing

calibration parameters for that step. Selecting YES and pressing the

P key will

cause the unit to store new calibration settings for the range selected. Pressing

D at any time will exit programming mode, but any range that has been

calibrated will maintain the new settings.

Current, Volt and Ohm Calibration Procedure

1. After entering CodE 48, select the input signal type (Curr, UoLt, rES) to be

calibrated.

2. Press the

P key until the desired range along with 2ER is displayed in the Line

2 units mnemonic.

3. Apply the zero input limit of the range indicated on Line 1 of the controller.

4. Press ! to select YES.

5. Press

P. Display will indicate ---- on Line 2 as the unit reads and stores the

new calibration parameter.

6. Display will indicate the desired range along with FUL in the Line 2 units

mnemonic

7. Apply the signal level indicated on Line 1 of the controller.

8. Press ! to select YES.

9. Press

P. Display will indicate ---- on Line 2 as the unit reads and stores the

new calibration parameter.

10. Repeat Preparation and Calibration Procedure for each Input Range to be

calibrated.

P

COdE

FCS

6 6

rSEt

COdE

FCS

5 0

P

COdE

FCS

5 1

P2C

U

x.xx

COdE

FCS

5 0

P

COdE

FCS

4 8

COdE

FCS

5 0

FACTORY SERVICE CODE

0

to

250

Enter the Service Code for the desired operation.

COdE

FCS

50

F1

F2

P

D

Pro

N O

Pro

F A C t

COdE

FCS

5 0