Appendix “a” - application example – Red Lion C48T User Manual

Page 36

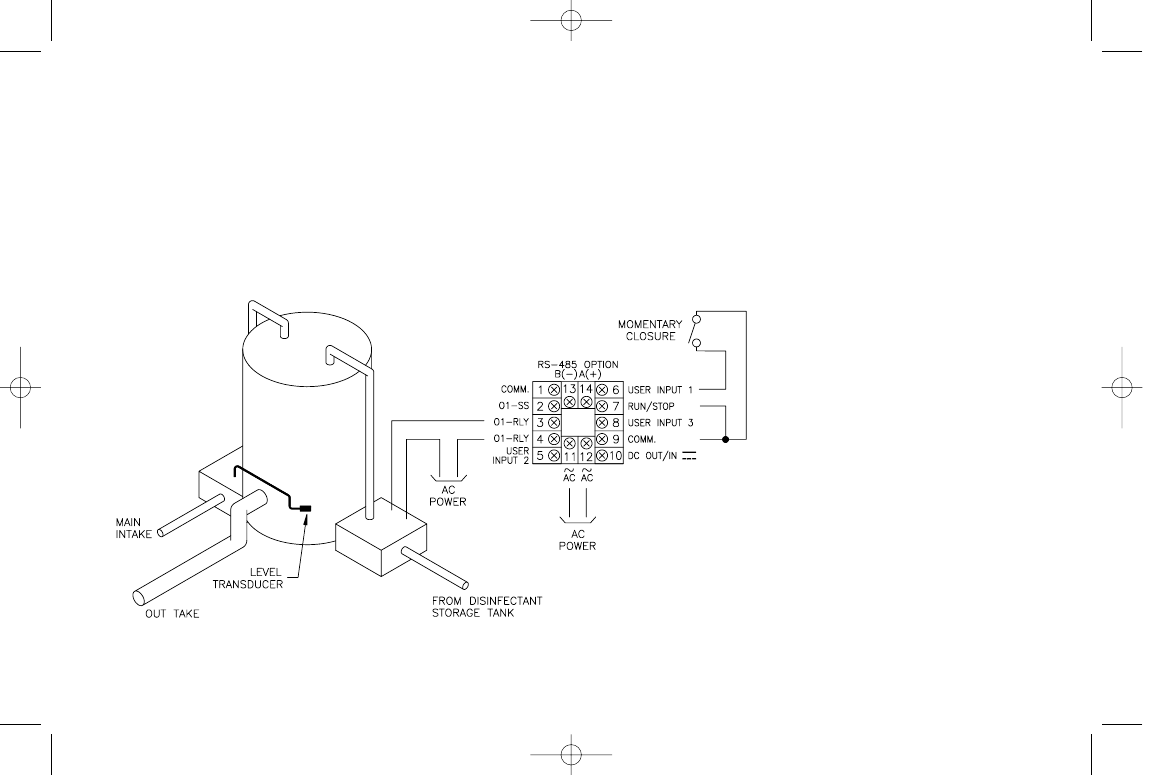

One Shot Timing Cycle

Proper wash down mixture for a food processing plant is an important factor

in maintaining the clean environment required. A disinfectant solution is added

to the mixing/holding tank used for the wash down cycle. When the holding

tank is near empty, a level transducer activates the filler pump. A C48TS is used

to turn on the disinfectant solution pump for a preprogrammed amount of time

during the filling process of the holding tank.

When the filler pump starts, a momentary contact closure activates User

Input 1, resetting the C48 Timer. The timer begins the timing cycle since the run

terminal is connected to common. The normally open relay contacts close at the

timer reset signal activating the disinfectant solution pump. When the

programmed preset is reached, timing stops and the relay deactivates, turning

off the pump controlling the disinfectant solution. The C48 Timer’s preset cycle

time may be changed according to the manufacturer’s concentration level of the

disinfectant.

APPLICATION PROGRAMMING

-30-

APPENDIX “A” - APPLICATION EXAMPLE

EntrY

AutoSc

trAnGE

OPEr

09

rSt.P.uP

no

Ac PrS

-Y

(yes)

PrESEt

xxxx.xx

rEVOut

-Y

(yes)

rEVAnu

-n

(no)

OutP.uP

-F

(off)

USrIn1

rSt-E

USrIn2

Pro.diS

USrIn3

ChgdSP

Usr F1

rSt-E

CodE

xxx

ScroLL

no

n.SEC

(min & sec)

C48t-im.QXD 3/5/04 3:29 PM Page 30