0 quick start guide, Proseries, Sonic-pro – Blue-White Sonic-Pro Hybrid Ultrasonic Flowmeters User Manual

Page 10: Select doppler or transit time mode, Select the transducer mounting location, Page 10, Front cover plate removed, Wiring compartment layout, Ok no no, Air bubbles may be present sediment may be present

Page 10

Sonic-Pro

Industries, Ltd.

Industries, Ltd.

ProSeries

by Blue-White Ind.

TM

2.0 Quick Start Guide

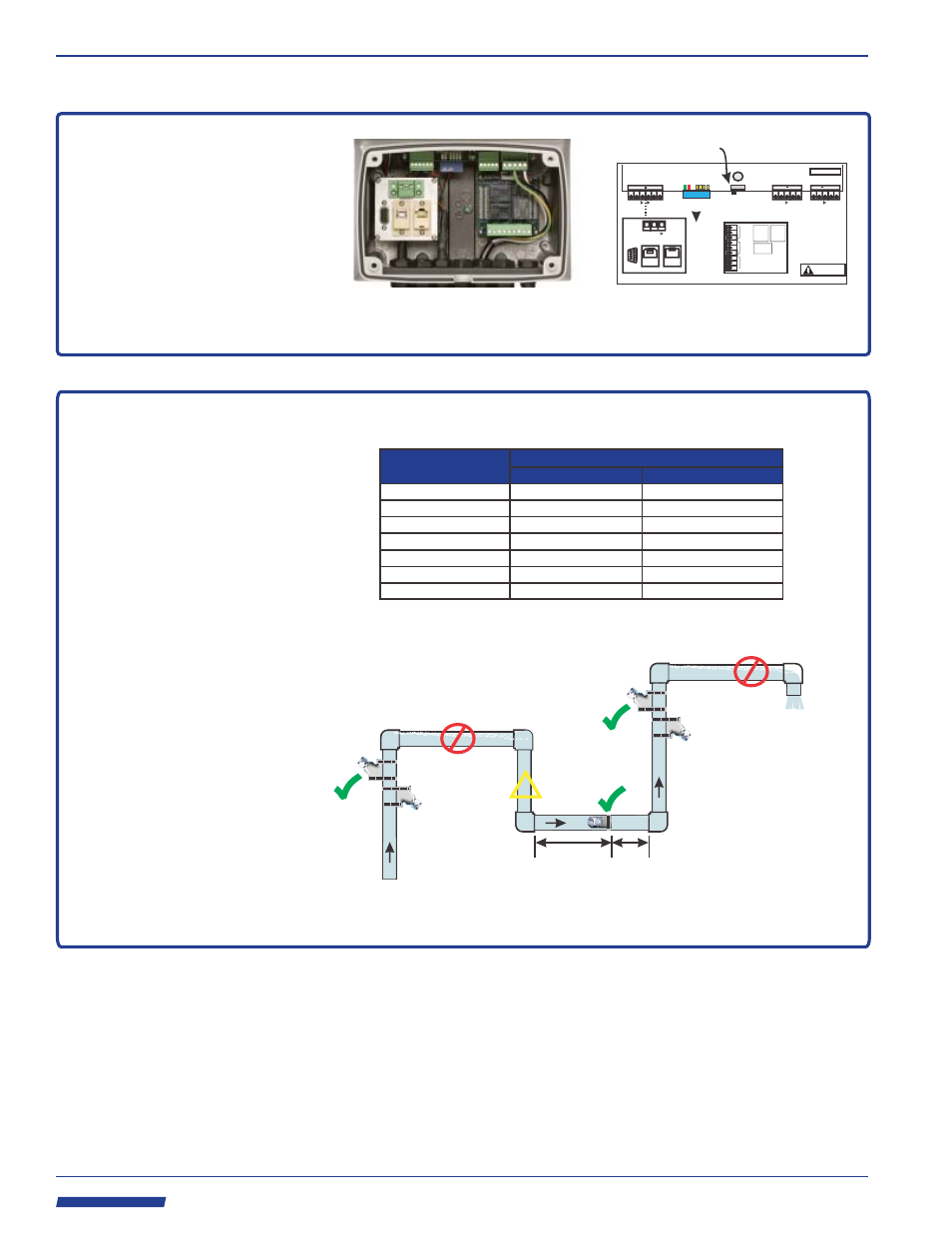

FRONT COVER PLATE REMOVED

1

Select doppler

or transit time

mode

Note that the meter is factory

set for Transit-Time operation.

RS232

USB

TRANSDUCER

INPUTS

Tx 1

RED (+)

BLK (-)

GRN

GRN

COMMUNICATIONS

CONNECTOR PANEL

RED (+)

MODE SELECT SWITCH

ETHERNET

RS485

PROCESS CONTROL RELAYS

(THREE EACH) 10A 250V AC

R1

R2

R3

COM

NC

NO

COM

NC

NO

COM

NC

NO

Tx 2

RED (+)

BLK (-)

mA

Hz

POS (+)

NEG (-)

GRN

SIGNAL

OUTPUTS

NEG (-)

POS (+)

DC

AC

DC (+)

DC (-)

GRN

AC LINE

AC NTRL

POWER INPUT

SD CARD

DATA LOG

(REMOVE)

MODE SWITCH

T

D

INDICATOR

LIGHTS

WARNING

INPUT POWER

LIMITS

AC INPUT

110VAC - 240VAC

50/60 Hz

DC INPUT

15 to 30 VDC

SETUP BUTTON

1A 250V (5 x 20)

FUSE

CAUTION

risk of electric shock

BLK (-)

GRN

WIRING COMPARTMENT LAYOUT

2

Select the transducer

mounting location

OK

OK

OK

NO

NO

Down flows

must have

back pressure

Pipe must be full

Air could be trapped

!

10 x D

5 x D

Flow

Direction

The flowmeter’s sound wave

beam only measures fluid that

actually passes through the

beam, therefore, the fluid

velocity must be consistent

across the entire pipe diameter

to ensure high accuracy. Flow

disturbances such as pumps,

elbows, tees, and valves in the

flow stream can cause swirl

patterns and vortices that will

affect the measurement.

Install the transducers on a

straight run of pipe as far as

possible from any

disturbances. The distance

required for accuracy will

depend on the type of

disturbance.

Type of Disturbance

Straight Lengths of Pipe Required

Upstream from Transducers

Flange

5 x Nominal Pipe Size

Reducer

o

90 Elbow

Gate valve

Pump

Downstream from Transducers

o

Two 90 Elbows - 1 Direction

o

Two 90 Elbows - 2 Directions

5 x Nominal Pipe Size

7 x Nominal Pipe Size

5 x Nominal Pipe Size

10 x Nominal Pipe Size

5 x Nominal Pipe Size

15 x Nominal Pipe Size

5 x Nominal Pipe Size

20 x Nominal Pipe Size

5 x Nominal Pipe Size

25 x Nominal Pipe Size

5 x Nominal Pipe Size

25 x Nominal Pipe Size

5 x Nominal Pipe Size

PIPE SYSTEM CONSIDERATIONS

MINIMUM STRAIGHT PIPE LENGTHS

See section 3.6 for more information

See section 6.1 for more information

NO

NO

Air bubbles may be present

Sediment may be present