Appendix, 4 order code – KROHNE BM 26 BASIC_ADVANCED EN User Manual

Page 84

9

APPENDIX

84

BM 26 BASIC/ADVANCED

www.krohne.com

10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

T

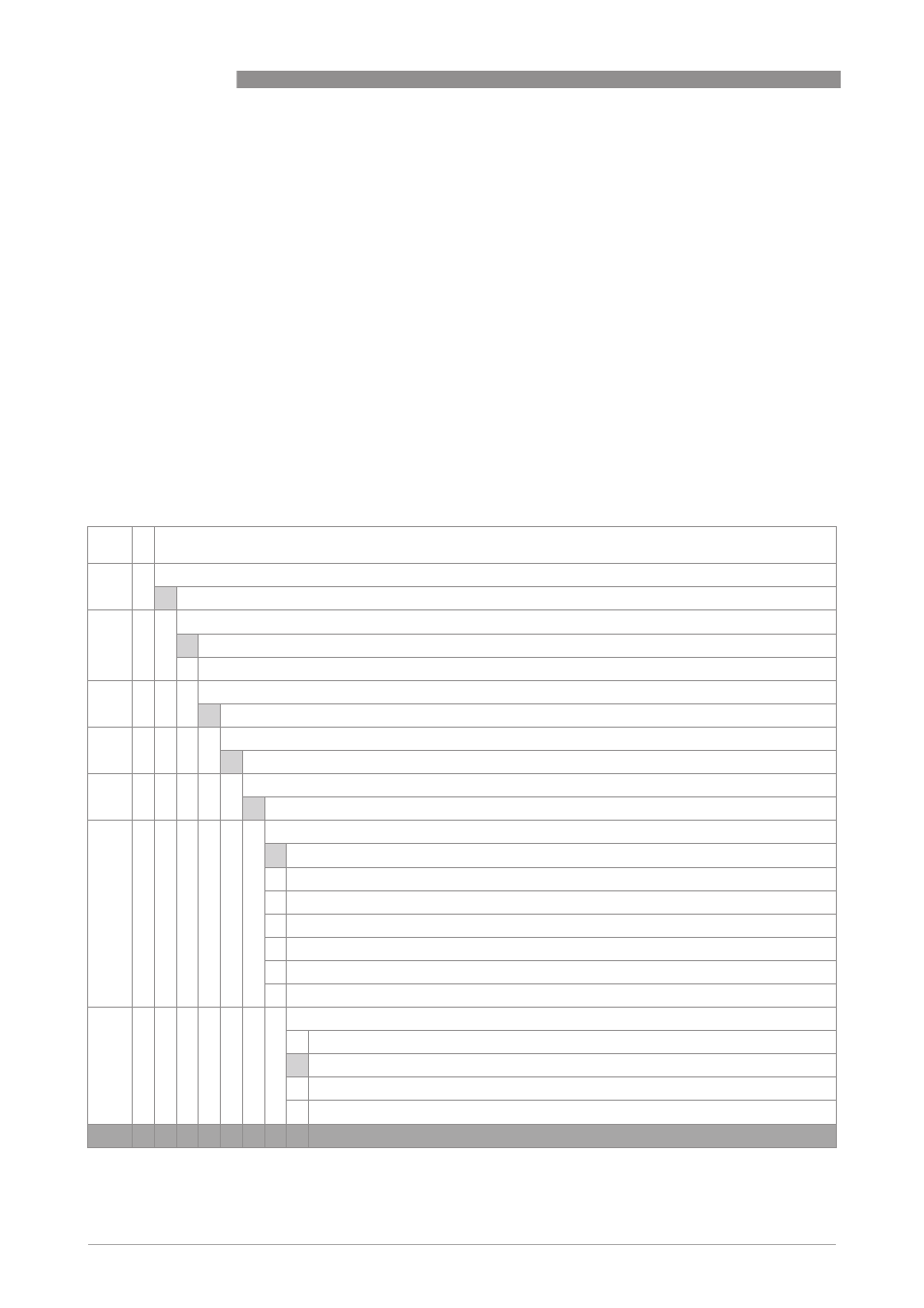

9.4 Order code

The characters of the order code highlighted in light grey describe the standard.

Basic version

TDR

TDR

TDR

TDR

Time domain reflectometry (TDR). The principle used by the TDR level

transmitter. For more data, refer to technical documentation for the

OPTIFLEX 1300 C.

TDR level transmitter

TDR level transmitter

TDR level transmitter

TDR level transmitter

An optional device (attached to the top of the measuring chamber) that

transmits low-intensity electromagnetic pulses along a rigid or flexible

conductor. When the pulses get to the surface of the product to be

measured, the pulses are reflected. The device measures the time from

when the pulse is transmitted to when it is received: half of this time is

equivalent to the distance from the reference point of the device (the thread

stop) to the surface of the product. The time value is converted into an

output. For more data, refer to technical documentation for the

OPTIFLEX 1300 C.

VF41 4 BM 26 Basic Magnetic bypass level indicator:

BM 26 Basic Magnetic bypass level indicator:

BM 26 Basic Magnetic bypass level indicator:

BM 26 Basic Magnetic bypass level indicator:

-40...+150

-40...+150

-40...+150

-40...+150°C and -16 bar max. / -40...300

C and -16 bar max. / -40...300

C and -16 bar max. / -40...300

C and -16 bar max. / -40...300°F and 232 psi max.

F and 232 psi max.

F and 232 psi max.

F and 232 psi max.

Material

Material

Material

Material

0 316L

Approval

Approval

Approval

Approval

0 Non-Ex

1 ATEX

Other approval

Other approval

Other approval

Other approval

0 Without

Process temperature

Process temperature

Process temperature

Process temperature

1 -40...+150°C (-40...+300°F)

Density [kg/l]/Float material

Density [kg/l]/Float material

Density [kg/l]/Float material

Density [kg/l]/Float material

1 0.8...1.19 / 316L

Orientation of process connections

Orientation of process connections

Orientation of process connections

Orientation of process connections

0 Lateral / Lateral

1 Bottom lateral / Top axial

2 Bottom axial / Top lateral

3 Axial / Axial

4 Bottom lateral / Top axial + 1 support bracket

5 Bottom axial / Top lateral + 1 support bracket

6 Axial / Axial + 2 support brackets

Process connection type

Process connection type

Process connection type

Process connection type

0 Without (3/8 NPTF for axial process connections)

1 Flange connection

2 Welded connection

3 Threaded connection (male)

VF41

VF41

VF41

VF41 4

Order code (complete this code on the pages that follow)

Order code (complete this code on the pages that follow)

Order code (complete this code on the pages that follow)

Order code (complete this code on the pages that follow)