Installation – KROHNE BM 26 BASIC_ADVANCED EN User Manual

Page 25

INSTALLATION

3

25

BM 26 BASIC/ADVANCED

www.krohne.com

10/2012 - 4000347004 - HB BM26 Basic/Adv R04 en

Switching point offset values

Installation of a limit switch for float failure detection

• Make sure the measuring chamber is empty and the float is in the chamber.

• Attach a limit switch to the bottom of the measuring chamber. Do not tighten the clamp.

• Connect the limit switch to the electrical circuit. Make sure that it is set to LOW limit

LOW limit

LOW limit

LOW limit. For more

data, refer to

Optional limit switches

on page 29.

• Energize the electrical circuit.

• Lift the limit switch up the measuring chamber until the limit switch status changes to open

open

open

open.

• Hold the limit switch tightly in this position and tighten the clamp.

i

The limit switch is in the correct position.

For more data, refer to Errors

Errors

Errors

Errors on page 37.

Definition of switching point offset

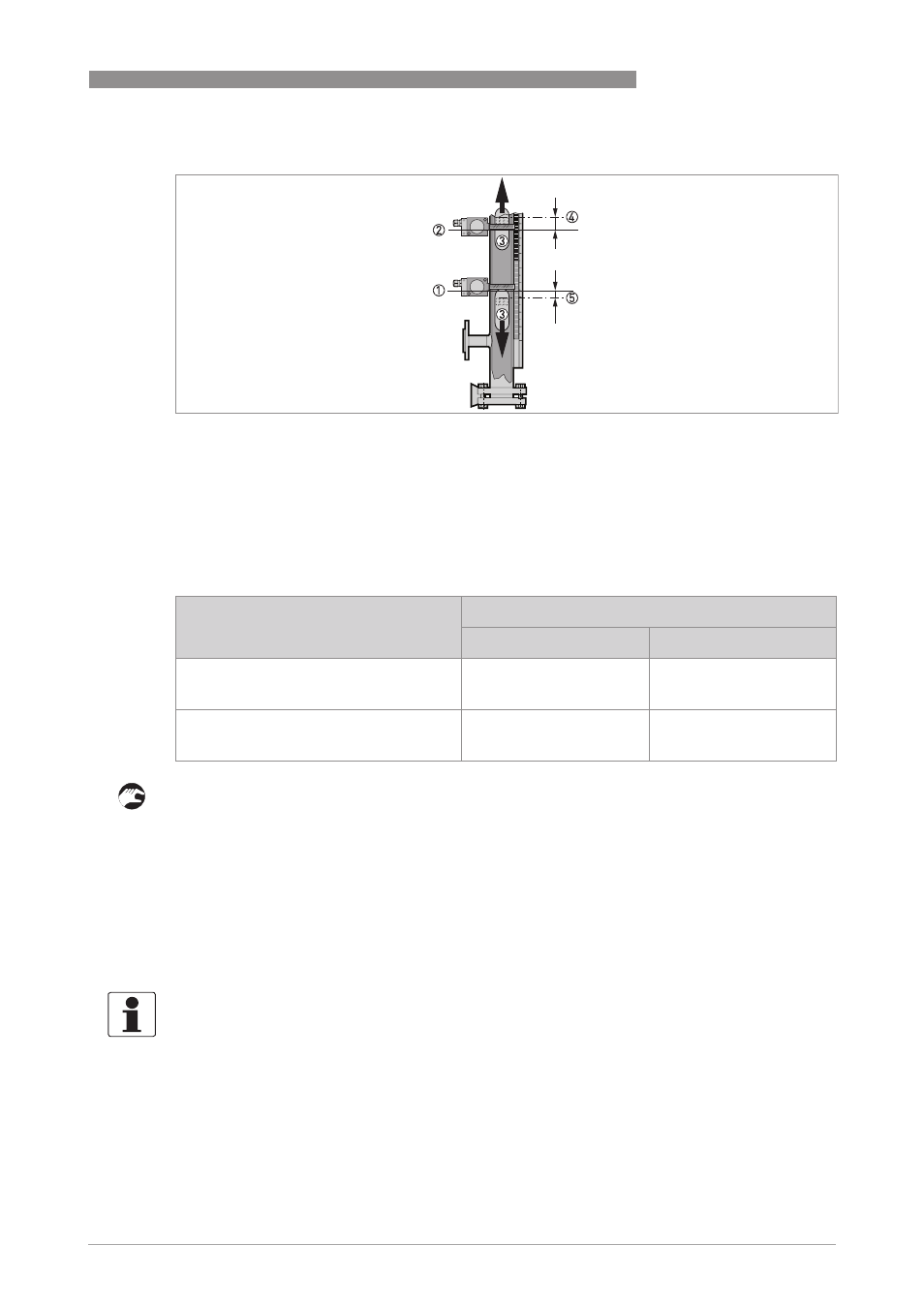

Figure 3-11: Switching point offset

1 Zero point of the limit switch

2 Zero point of the limit switch

3 Float and float magnet (switching point is in relation to the top of the magnet)

4 True switching point above a limit switch (the switch is open when the liquid level goes above this point - a HIGH limit

HIGH limit

HIGH limit

HIGH limit

switch)

5 True switching point below the limit switch (the switch is open when the liquid level goes below this point - a LOW limit

LOW limit

LOW limit

LOW limit

switch)

Conditions

Switching point offset, a

mm

inches

When the switch must be open above the

switching point (a HIGH limit

HIGH limit

HIGH limit

HIGH limit switch),

move the switch below the switching point:

15

0.6

When the switch must be open below the

switching point (a LOW limit

LOW limit

LOW limit

LOW limit switch),

move the switch above the switching point:

0

0

a

a

INFORMATION!

The float will go to the bottom of the measuring chamber for the reasons that follow:

•

damaged or corroded float (float failure),

•

liquid density that does not correspond to the specifications received with the order and

•

draining the measuring chamber