Probe burn off, Carbon probe burn off requirements, Burn off procedures – Watlow 8LS Controller User Manual

Page 120

112 8LS User’s Guide

Appendix B: 8LS-CP

Probe Burn Off

Carbon Probe Burn Off Requirements:

1. To burn off carbon, excess fresh air is supplied to the end of the

probe.

2. The excess fresh air burning off the carbon will cause the temperature

of the probe to increase. The temperature must be monitored from the

probe internal T/C, so that the maximum temperature of the probe is

not exceeded.

3. The excess fresh air flow requirement is 1 to 2 SCFH.

4. The frequency and length of the burn off may be controlled from a

timer or from a contact.

5. The frequency is normally measured in hours and the amount of time

for the burn off is in minutes.

6. The CP controller PID output must be maintained, so that there is no

change of the enriching gas, due to the misreading of the CP probe

during burn-off.

7. The level of the PID control signal must be maintained following the

burn off cycle to allow the probe to recover before automatic control

is restored.

8. The method of burn-off is determined by the type of furnace.

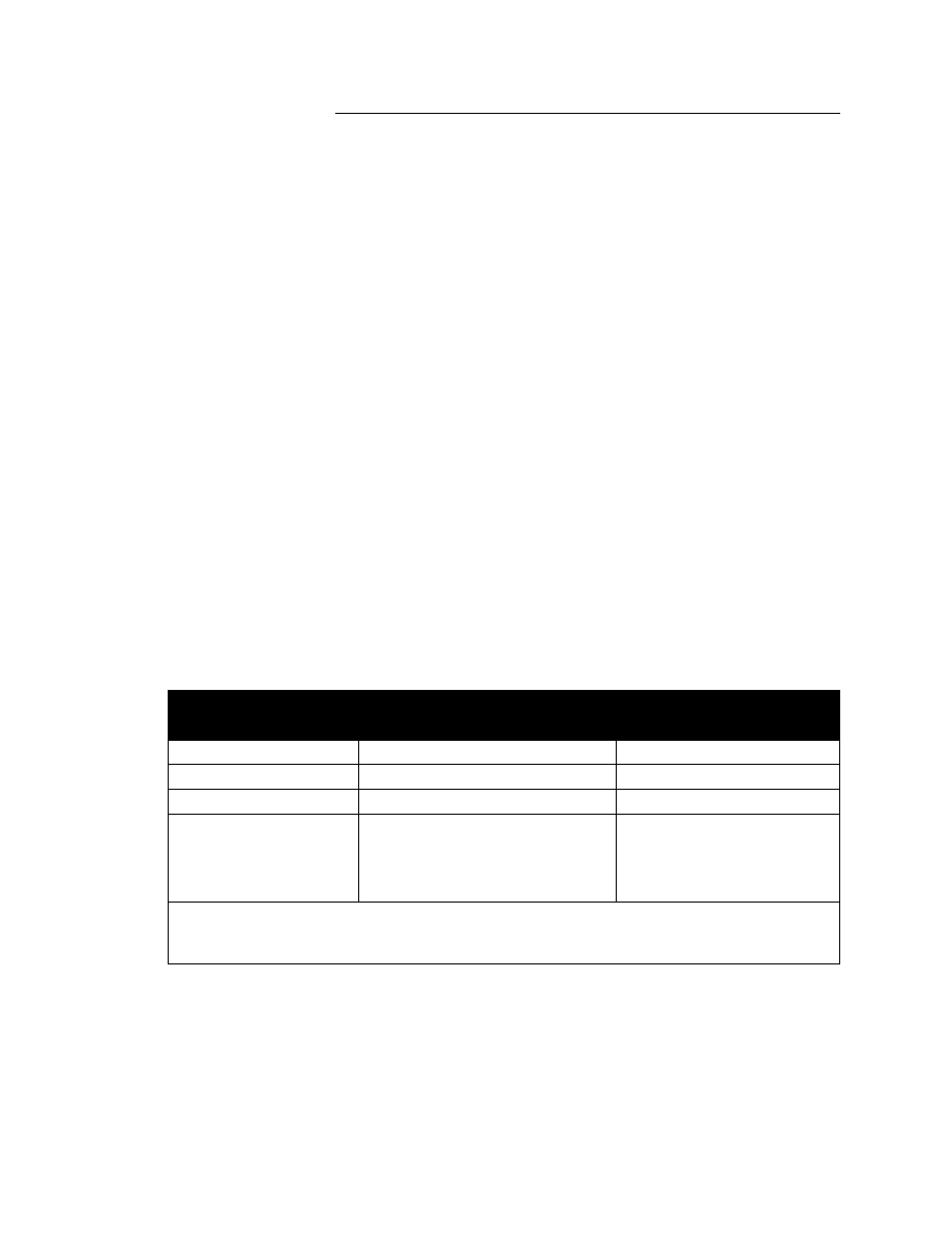

Burn off Procedures

Continuous Furnace

(In time mode)

Batch Furnace

(in input mode)

Recommended air flow

2 SCFH

1 SCFH

Purge period

5 minutes set by operator

Time set by operator

Burn off cycle

3 hours set by operator

Cycles with open door

Method of operation

1. Hold enrichment gas at current

level during purge cycle.

2. Monitor carbon probe tempera-

ture with the built in T/C.

1. Disable enrichment gas

during cycle.

2. Monitor carbon probe tem-

perature with the built in T/C.

Set the SP for maximum probe temperature of either 1900 or 2100ºF. The carbon burn off

cycle will stop if temperature exceeds the limit. The burn off will continue when tempera-

ture goes below the limit.