Warner Electric PCBC-1525_1225 User Manual

Page 8

8

Warner Electric • 800-825-9050

P-214

•

819-0518

PCB-1225/1000, PCB-1525/1225

Clutch-Brake Spline Drive Armature

The illustration drawings, parts lists, and exploded

views for these units can be found beginning on

page 20.

Refer to the installation instructions for pin drive

armature units, page 3, for steps A-E.

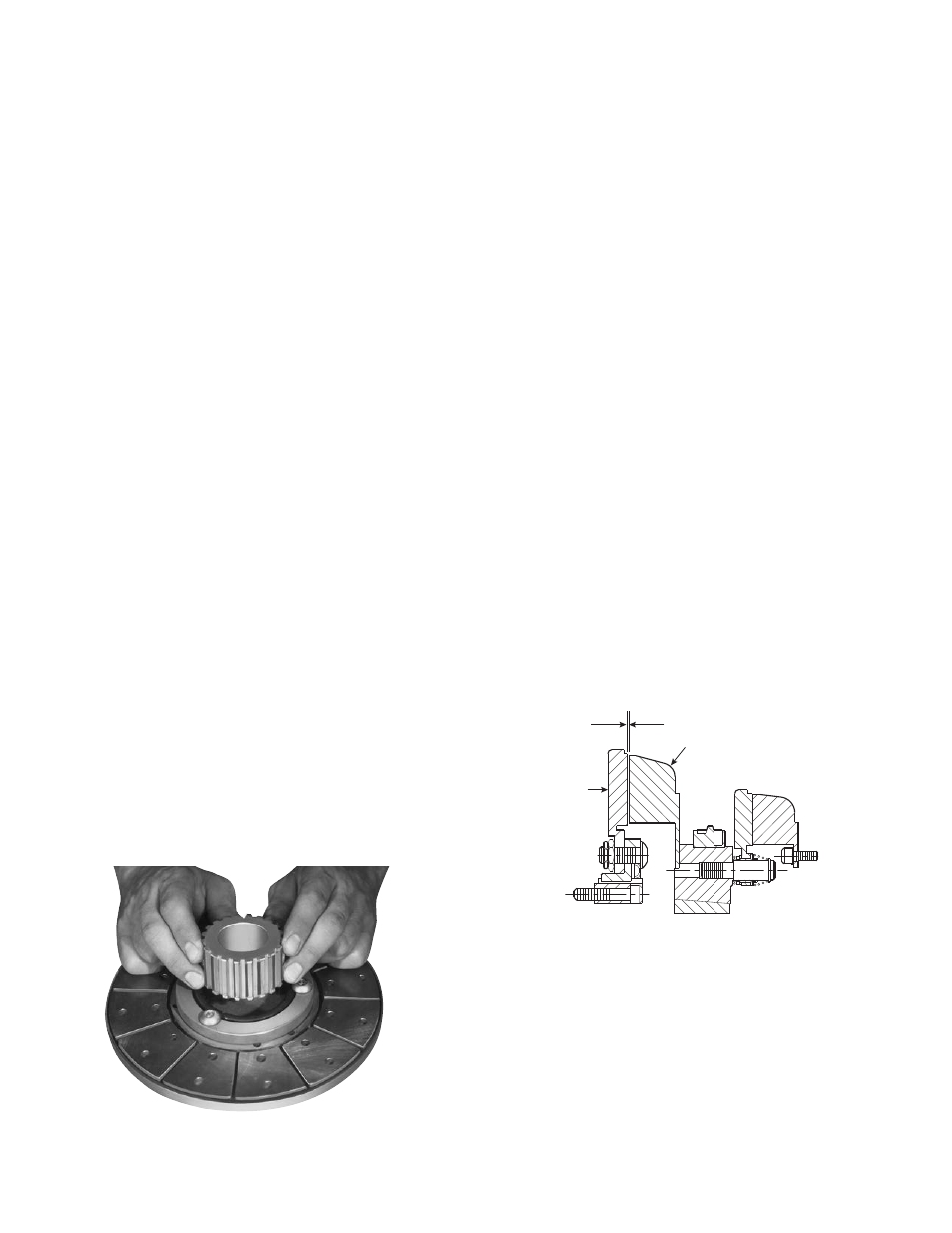

F. Assembling the Spline Drive Clutch

Armature

1. These clutch/brake units contain spline drive

armatures and hubs. The armatures are shipped

with a built-in autogap spring accessory. This

device automatically maintains a gap of about

1/32 inch between the armature and magnet

faces for the life of the unit.

The spline drive armature assembly is shipped

with the armature, splined armature adapter,

and autogap already assembled. The splined

hub and capscrew accessories are shipped as

separate parts.

Follow these instructions to assemble the

splined armature assembly and hub:

a. Place the armature-adapter assembly on a

flat surface with the segmented side up.

b. Push the splined hub, with the pilot diameter

down (refer to illustration drawings) through

the autogap spring and splined armature

adapter. (Figure 12)

2. A customer may mount the clutch armature to

his own pulley, hub, gear, etc. Refer to the illus-

tration drawings, "End View of the Armature,"

page 20, for the dimensional information need-

ed to drill and tap holes in the customer part.

The splined hub pilot diameter must be concen-

tric with the splined armature center of rotation

within .010 T.I.R.

3. Mount the armature to the customer's part

using the capscrew accessory provided.

Maintain a 1/16-inch clearance between the

armature adapter and the customer part after

the parts have been assembled.

G. Mounting the Clutch Armature

Assembly

1. Slide the complete armature assembly on to the

shaft.

2. Adjust the armature's position to allow a 1/16-

inch gap between the magnet and armature

faces. (Figure 13)

3. Secure the armature and customer supplies

pulley, sprocket or hub assembly in position by

a) retainer rings, b) set collars, c) shoulder on

the shaft, or d) any combination of these. The

best method will depend on the characteristics

of each application.

Figure 12

1/32-inch

Clutch Magnet

Armature

Figure 13