C. assembling the clutch magnet and magnet hub, D. assembling the brake armature and magnet hub, Figure 4 figure 5 figure 6 – Warner Electric PCBC-1525_1225 User Manual

Page 10

10

Warner Electric • 800-825-9050

P-214

•

819-0518

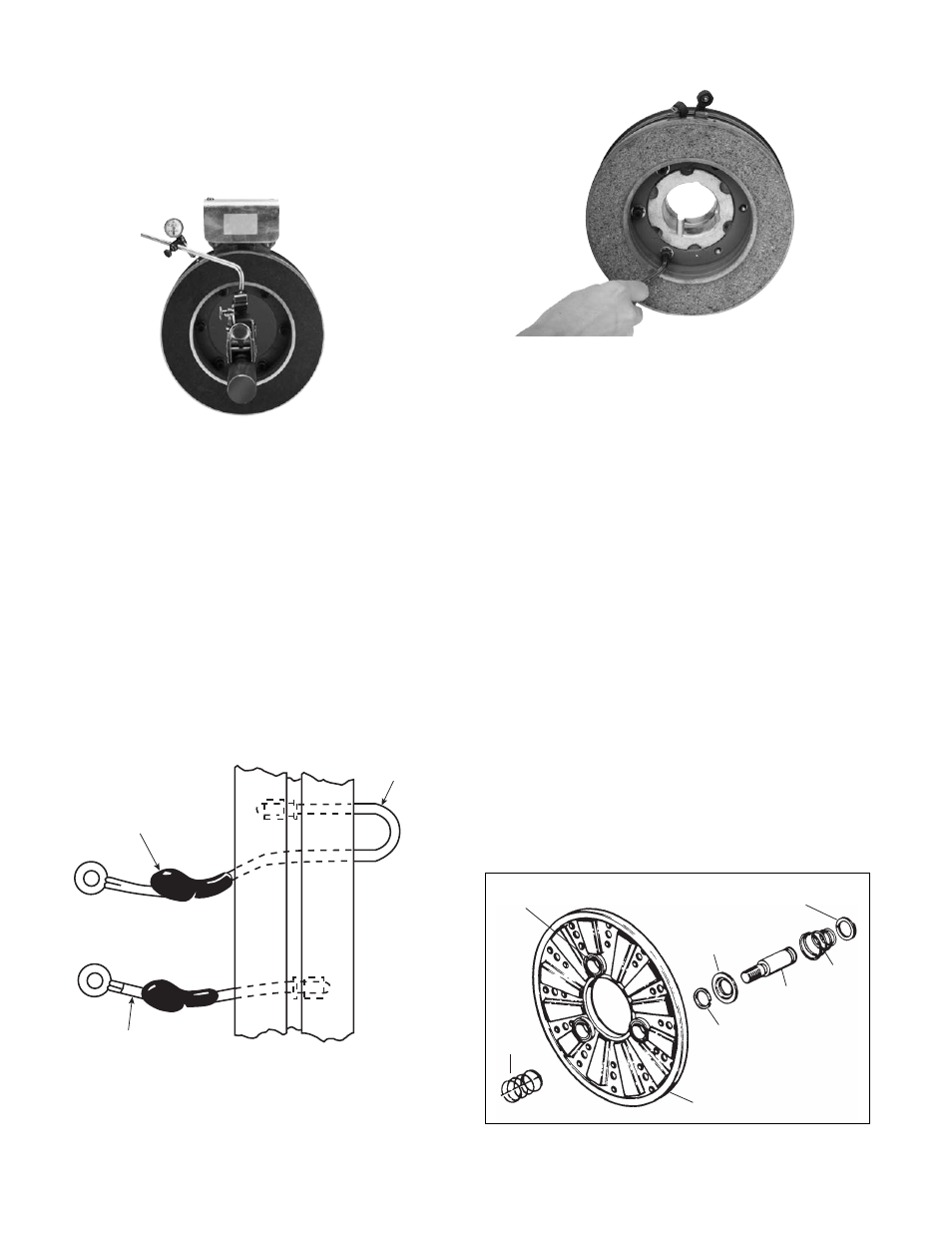

4. Use a dial indicator to check the unit for con-

centricity and squareness to the shaft. The unit

should be concentric within .010 T.I.R. and

square within .006 T.I.R. (See Figure 3.)

C. Assembling the Clutch Magnet and

Magnet Hub

1. Insert the lead wires through the rubber termi-

nal caps and onto the collector ring. The short-

er wire goes into the hole in the front of the ring

(the side that will be mounted to the magnet).

The longer wire goes through the ring and into

the hole in the back.

Press the bullet-type connectors firmly into

place. (See Figure 4.)

2. Mount the magnet to the magnet hub using

capscrews and lockwashers. (See Figure 5.)

3. Secure the lead wires to the magnet terminals

with screws and lockwashers.

4. Pull the rubber caps over the terminals.

D. Assembling the Brake Armature and

Magnet Hub

Assemble the armature to the magnet hub with the

autogap mounting accessory.

The autogap assembly is a double spring device

which allows for automatic armature clearance and

adjustment for wear. The smaller or conical spring

pushes the armature from the magnet face, leaving

a gap of about 1/32 inch, while the straight spring

automatically follows up for wear. This combination

maintains maximum efficiency throughout the life of

the unit.

The assembly procedure for the autogap accesso-

ry is as follows (Figure 6):

Figure 3

Short

Wire

Collector

Ring

Terminal

Cap

Long

Wire

Figure 4

Figure 5

Figure 6

Retainer Ring

Heavy

Spring

(Red)

Detent

Spring

Retainer

Detent

Spring

Drive

Pin

Straight

Spring

(White)

Armature

Boss

Armature