F. assembling the clutch armature – Warner Electric PCBC-1525_1225 User Manual

Page 6

6

Warner Electric • 800-825-9050

P-214

•

819-0518

3. Position the assembly to allow a gap of about

1/32-inch between the brake magnet and arma-

ture faces. (Figure 11)

Once this gap is set, it will be automatically

maintained for the life of the unit.

4. Secure the assembly in this position on the

shaft by alternately tightening each setscrew.

During the tightening process, the bushing

should be tapped lightly to make certain it

seats-in properly.

Note: For pin drive armatures (normal duty), con-

tinue to F. on page 7. For spline drive armatures

(heavy duty), proceed to F. on page 7.

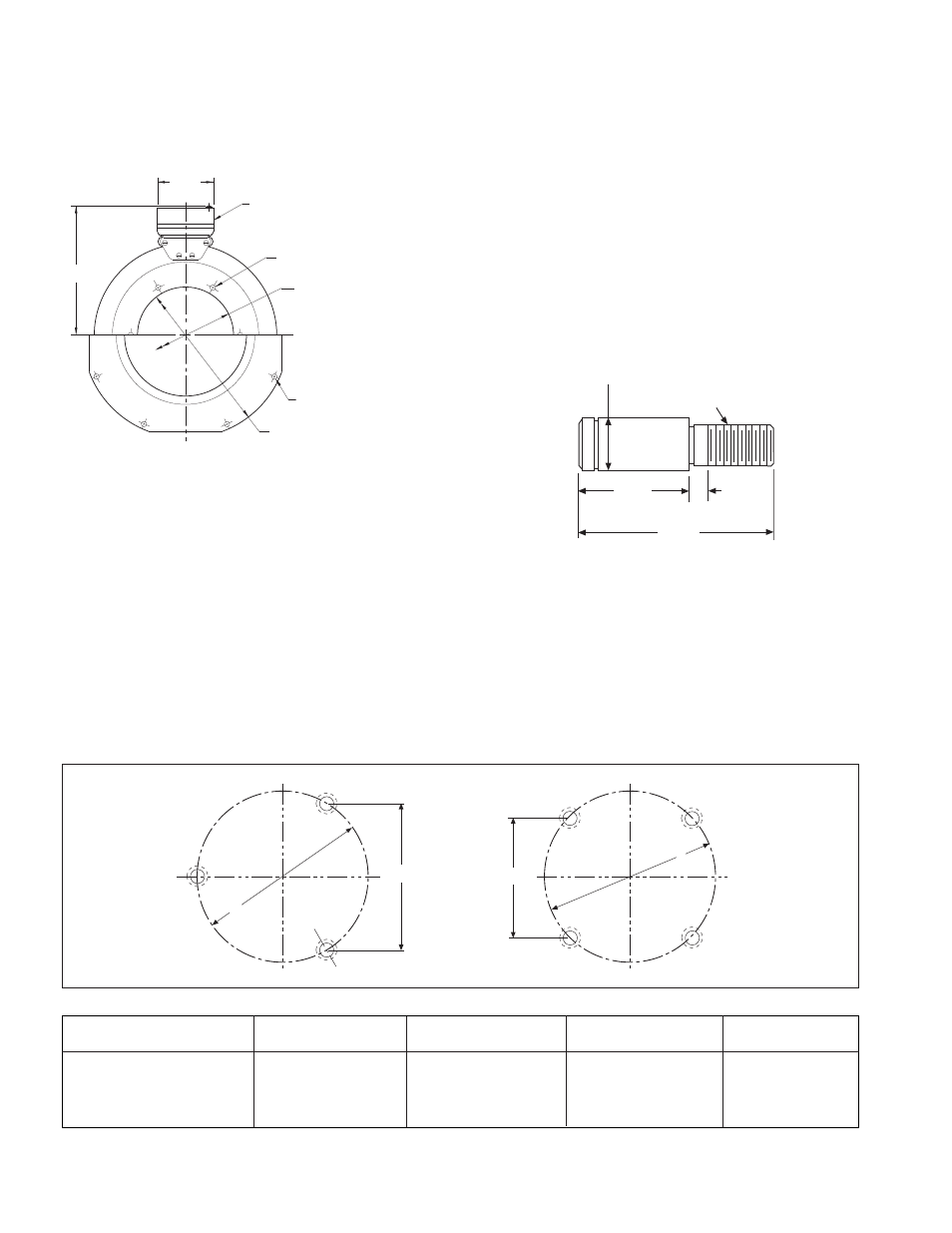

F. Assembling the Clutch Armature

1. A customer may wish to use the autogap

accessory to mount a clutch armature to his

own pulley, hub, gear, etc. Follow the illustrated

dimensions (Figures 12 & 13) to properly adapt

these parts to the armature.

a. Chordal dimensions "A" and "C" must be

held for all chords between pin holes.

b. Drill 27/64-inch diameter holes to a sufficient

Figure 11

Figure 12

Machining Instructions for Gear, Sprocket, or Pulley

Unit Size

A

B

C

D

1000

4.548 ± .002

5.252 ± .002

1225

4.155 ± .002

5.877 ± .002

1525

6.010 ± .002

8.500 ± .002

A

C

D

B

1-9/32"

5/16"

2-1/4"

1/2"–13 UNC–3A

Threads

+.0005"

.6185"

Dia.

–.0010"

Figure 13

Removable plug in

ends for 1/2" con

-

duit.

7.687 Max.

11.500/11.498 Pilot

Dia.

.358/.338 dia. (8) holes equally

spaced on 10.625 dia.*

.358/.338 dia. (6) holes

equally spaced on 6.125 dia.*

5.378/5.376 Pilot

Dia.

3.750