TREND NX Variable Speed Drives User Manual

Page 121

104 • vacon

FAULT TRACING

Tel. +358 (0)201 2121 • Fax +358 (0)201 212 205

9

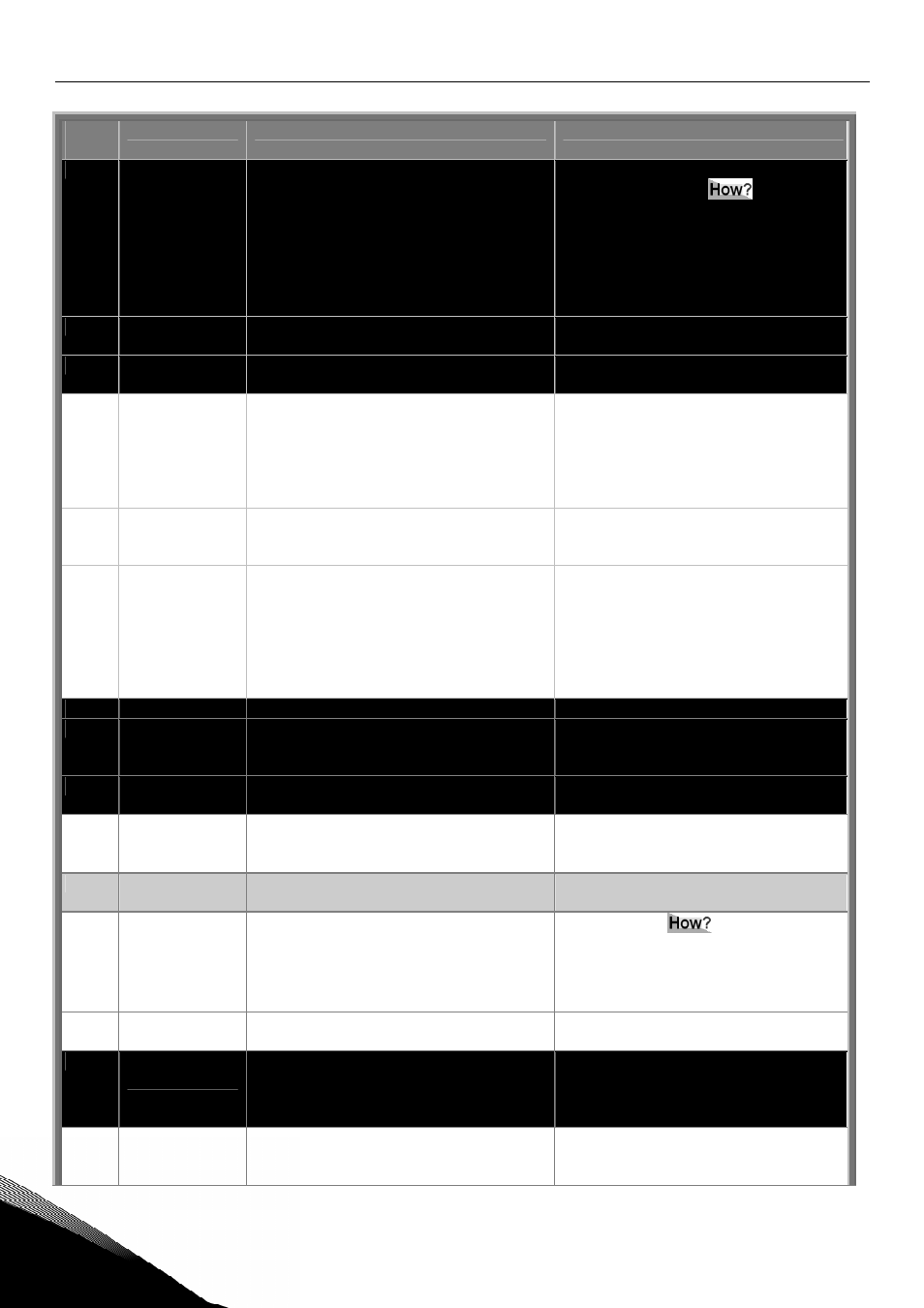

Fault

code

Fault

Possible cause

Correcting measures

9

Undervoltage

DC-link voltage is under the voltage limits

defined in Table 4-7.

− most probable cause: too low a supply

voltage

− frequency converter internal fault

In case of temporary supply voltage

break reset the fault

and restart

the frequency converter. Check the

supply voltage. If it is adequate, an

internal failure has occurred.

Contact the distributor near to you.

Please visit:

10

Input line

supervision

Input line phase is missing.

Check supply voltage and cable.

11

Output phase

supervision

Current measurement has detected that

there is no current in one motor phase.

Check motor cable and motor.

12

Brake chopper

supervision

− no brake resistor installed

− brake resistor is broken

− brake chopper failure

Check brake resistor.

If the resistor is ok, the chopper is

faulty. Contact the distributor near to

you.

Please visit:

13

Frequency con-

verter under-

temperature

Heatsink temperature is under –10°C

14

Frequency con-

verter over-

temperature

Heatsink temperature is over 90°C (or

77ºC, NX_6, FR6).

Overtemperature warning is issued when

the heatsink temperature exceeds 85°C

(72ºC).

Check the correct amount and flow of

cooling air.

Check the heatsink for dust.

Check the ambient temperature.

Make sure that the switching frequency

is not too high in relation to ambient

temperature and motor load.

15

Motor stalled

Motor stall protection has tripped.

Check motor.

16

Motor over-

temperature

Motor overheating has been detected by

frequency converter motor temperature

model. Motor is overloaded.

Decrease the motor load.

If no motor overload exists, check the

temperature model parameters.

17

Motor

underload

Motor underload protection has tripped.

22

EEPROM

checksum fault

Parameter save fault

− faulty operation

− component failure

24

Counter fault

Values displayed on counters are

incorrect

25

Microprocessor

watchdog fault

− faulty operation

− component failure

Reset the fault

and restart.

Should the fault re-occur, contact the

distributor near to you.

Please visit:

26

Start-up

prevented

Start-up of the drive has been prevented.

Cancel prevention of start-up.

29

Thermistor

fault

The thermistor input of option board has

detected increase of the motor

temperature

Check motor cooling and loading

Check thermistor connection

(If thermistor input of the option board is

not in use it has to be short circuited)

31

IGBT temperature

(hardware)

IGBT Inverter Bridge overtemperature

protection has detected too high a short

term overload current

Check loading.

Check motor size.