Operating tips, Do not bend at tight angle, Do not force the tool – Foredom Series SR User Manual

Page 6

Operating Tips

Your Foredom motor may be operated in a vertical or

horizontal position, but it should not be enclosed or

confined so as to restrict air circulation. If the motor is

hung up above a workbench, be sure it is fastened secure-

ly to the wall or motor hanger. The motor may develop a

high operating temperature (up to 100

o

F + ambient) after

prolonged use, and it will be too hot to hold. This will not

harm the motor which is designed to operate at this

temperature for prolonged periods.

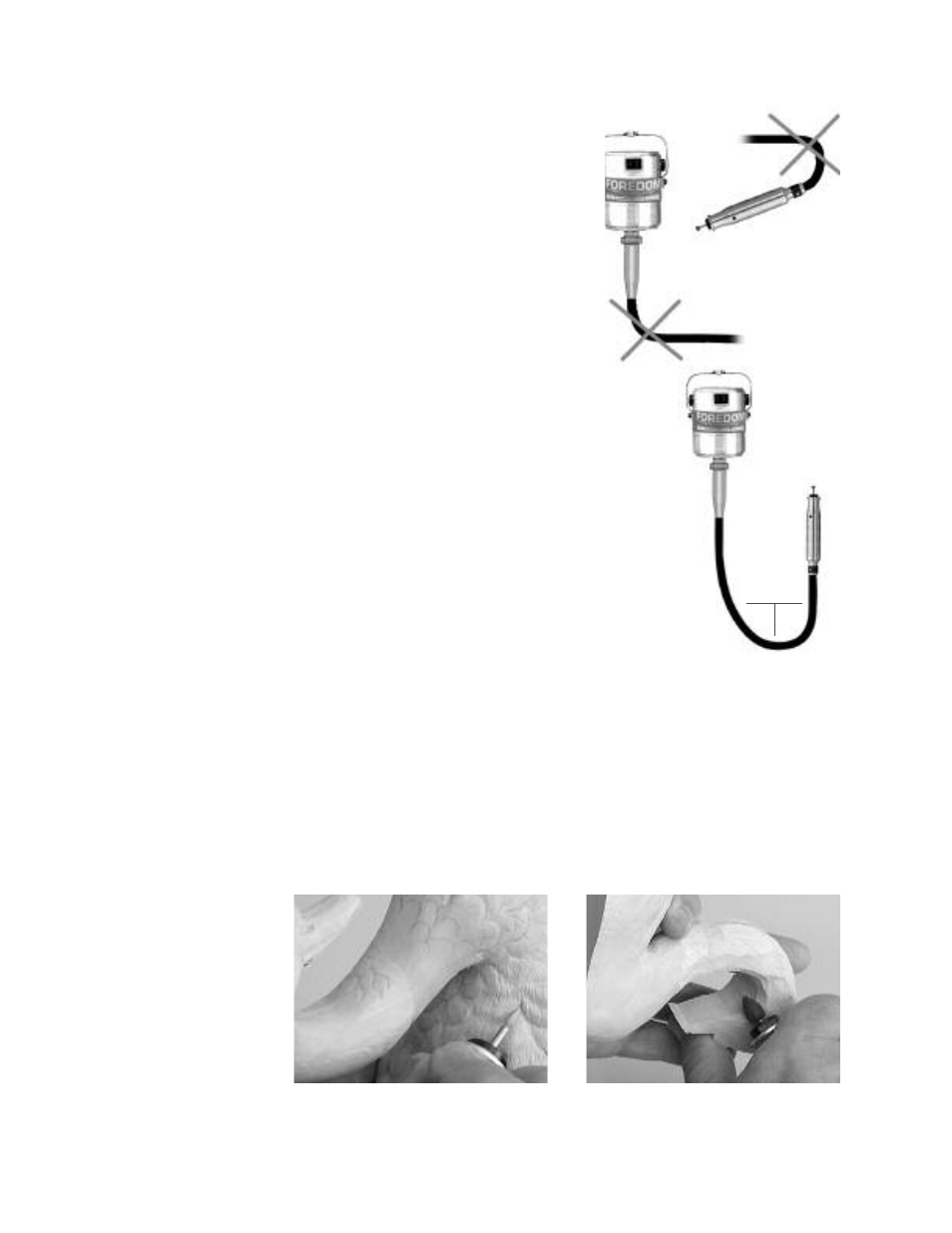

Do Not Bend at Tight Angle

Shafts and sheaths are stronger and last longer when they are

used without sharp bends. If used at angles or loops, wear will

occur at the points of greatest friction. When operating your power

tools be careful not to bend the flexible shaft too much at either the

handpiece or motor shaft connections. Excessive heat and wear will

occur if the bend is too great.

Follow these guidelines for trouble-free use–

a 4″ or larger radius, as shown to the right, should be maintained for

shafts on all motors. In its normal curved position, Series SR flexible shaft

machines can tolerate up to 12 lbs. of torque. There is no way to avoid

ultimate wear and under normal conditions a flexible shaft machine may

require several replacement shafts and sheaths during its life-time.

Do Not Force the Tool

Let the speed of the tool do the work. A light touch is always advised. Use extra caution when

carving around an edge, especially when using Typhoon

®

or other aggressive burs. Applying

excessive side pressure may cause the shank or shaft of any accessory to bend or break. It is also

important to insert the shank or shaft of an accessory or mandrel into the collet or chuck of the

handpiece as far as possible in order to provide proper support. The collet or chuck should also

be securely tightened before use. Generally, slower speeds are used when greater control over the

accessory is required for precise, delicate work. Higher speeds are used for carving (shaping and

stock removal) buffing, cutting and polishing metals.

Do Not

Do This!

Minimum

Operating

Radius

4

″ radius

4″

ra

di

us

6

Begin with a light

touch when applying

an accessory to the

work piece, and

experiment with

different angles for

achieving the results

you want.