Foredom Series H Motors User Manual

Foredom, Series txh, srh, lxh, and h motors, H.28h

Special Insert for Assembly,

Operation, and Maintenance of

Series TXH, SRH, LXH, and H Motors

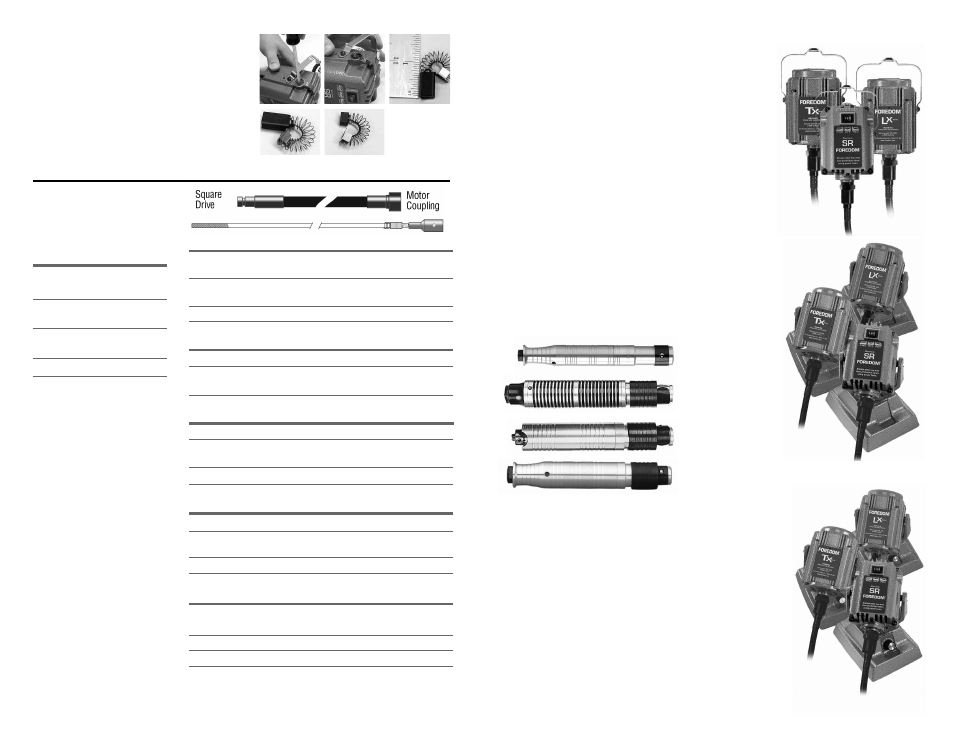

The models shown at right come equipped with longer, square

drive shafts and heavy duty protective sheaths that are different

from those on our standard TX, SR, and LX motors.

As a result, they can only be used with Foredom’s four square

drive style handpieces.

Aside from the assembly and maintenance of these unique items,

all other operating instructions and safety guidelines apply. Please

read manuals carefully and completely.

Square Drive Handpieces for TXH, SRH, LXH,

and H Motors

These handpieces are used with heavy duty “square drive”

shafts ONLY. They are unique products and not part of Foredom’s

system of interchangeable handpieces. They have permanently

lubricated and shielded ball bearings for cool running and

continuous use. H.25H, H.30H, and H.44HT have positive sheath

locking mechanisms (locking rings). The new H.28H attaches

without a locking ring.

H.28H is a slender,

collet-type handpiece with tapered front grip.

Comes with 1/8

″ and 3/32″ collets. 23/32″ dia., 5

11

⁄

16

″ long.

H.25H comes with 1/8

″ and 1/4″ collets and has larger,

double shielded ball bearings. Precision collets from 1/16

″ to 1/4″

and metric sizes are available. 1

1

⁄

32

″ dia., 6

1

⁄

8

″ long.

H.30H has a geared 3-jaw #0 chuck with 0-5/32

″ (4mm) capacity.

Includes chuck key in molded plastic handle. 1

″ dia., 5

13

⁄

16

″ long.

H.44HT is a collet-type handpiece with 1/8

″, 3/32″ and 1/4″

collets. Additional collet sizes from 1/16

″ to 1/4″ in 1/32″

increments and metric sizes are available. 1

″ dia., 6

1

⁄

4

″ long.

Refer to Owners Manual or Handpiece Instructions for

information on Attaching Accessories to Handpieces.

M.TXH, M.SRH & M.LXH Hang-Up Style

M.TXBH, M.SRBH,

& M.LXBH

Bench Style

M.TXMH, M.SRMH,

& M.LXMH

Bench Style

with built-in

control

FOREDOM

®

The Foredom Electric Company

Bethel, CT 06801

Email:

[email protected]

www.foredom.net

Form 902H n 5/12

H.25H

H.30H

H.44HT

Recommended Spare

Parts and Supplies to

keep on hand to insure

continuous operation

MP319P

Series TXH and LXH

Pair Motor Brushes

MP132P

Series SRH Pair

Motor Brushes

MS10006 Foredom

Flexible Shaft Grease

UA115

3/32

″ Hex key

MP2019P Discontinued Series H

Pair Motor Brushes

A copy of the owner’s manual

for any of these motors can be

downloaded from our website.

Also, visit our website for

‘how to’, maintenance and

product feature videos:

www.foredom.net

Square Drive Shafts and Sheaths for Series SRH, TXH, LXH

S-10823

63

3

⁄

4

″ Square Drive Shaft–Comes supplied on

motors cited above

S-10801TX

63

″ Heavy Duty Sheath Assembly (includes SS10819)

Comes supplied on motors cited above

SS10819

Silencer Spring for motors cited above

S-10816TX

Prelubricated Complete Assembly (S-10823,

S-10801TX & SS10819)

S-10827-NC

63

13

⁄

16

″ Non-Conductive Square Drive Shaft

S-10801-NC

63

1

⁄

8

″ Non-Conductive Heavy Duty Sheath

(includes SS10819 Silencer)

S-10816-NC

Non-Conductive Prelubricated Complete Assembly

(S-10827-NC, 10801-NC & SS10819)

S-10805

45

3

⁄

4

″ Square Drive Shaft

S-10802TX

43

3

⁄

4

″ Heavy Duty Sheath Assembly

(includes SS10822 Silencer)

SS10822

Silencer Spring

S-10804TX

Prelubricated Complete Assembly (S-10805,

S-10802TX & SS10822)

S-10805-NC

45

3

⁄

4

″ Non-Conductive Square Drive Shaft

S-10802-NC

43

3

⁄

4

″ Non-Conductive Heavy Duty Sheath

(includes SS10822 Silencer)

SS10822

Silencer Spring

S-10804-NC

Non-Conductive Prelubricated Complete Assembly

(S-10805-NC, S-10802-NC & SS10822)

Square Drive Shafts and Sheaths for Discontinued Series H

S-10805

45

3

⁄

4

″ Square Drive Shaft

S-10802A

44

3

⁄

8

″ Heavy Duty Sheaths, includes SS10822

SS10822

Silencer Spring

S-10804B

Prelubricated Complete Assembly

(10805, 10802A & SS10822)

FOREDOM

®

Replacement of Motor Brushes

Motor brushes should be checked for wear periodically.

When new they are approximately 3/4

″ (19mm) long.

Replace them when they have worn to 1/4

″ (6mm). To

remove brushes, disconnect motor power cord and

unscrew the brush caps. Remove the worn motor

brushes, replace with new motor brushes, and screw

motor brush caps back on. Be sure to replace both

motor brushes even if one of them seems less worn

than the other.

New Motor Brush Motor Brush that

needs replacement

4

H.28H