IAI America LSAS-N15HM User Manual

Page 68

13. Replacement/Adjustment of Stainless Sheet

52

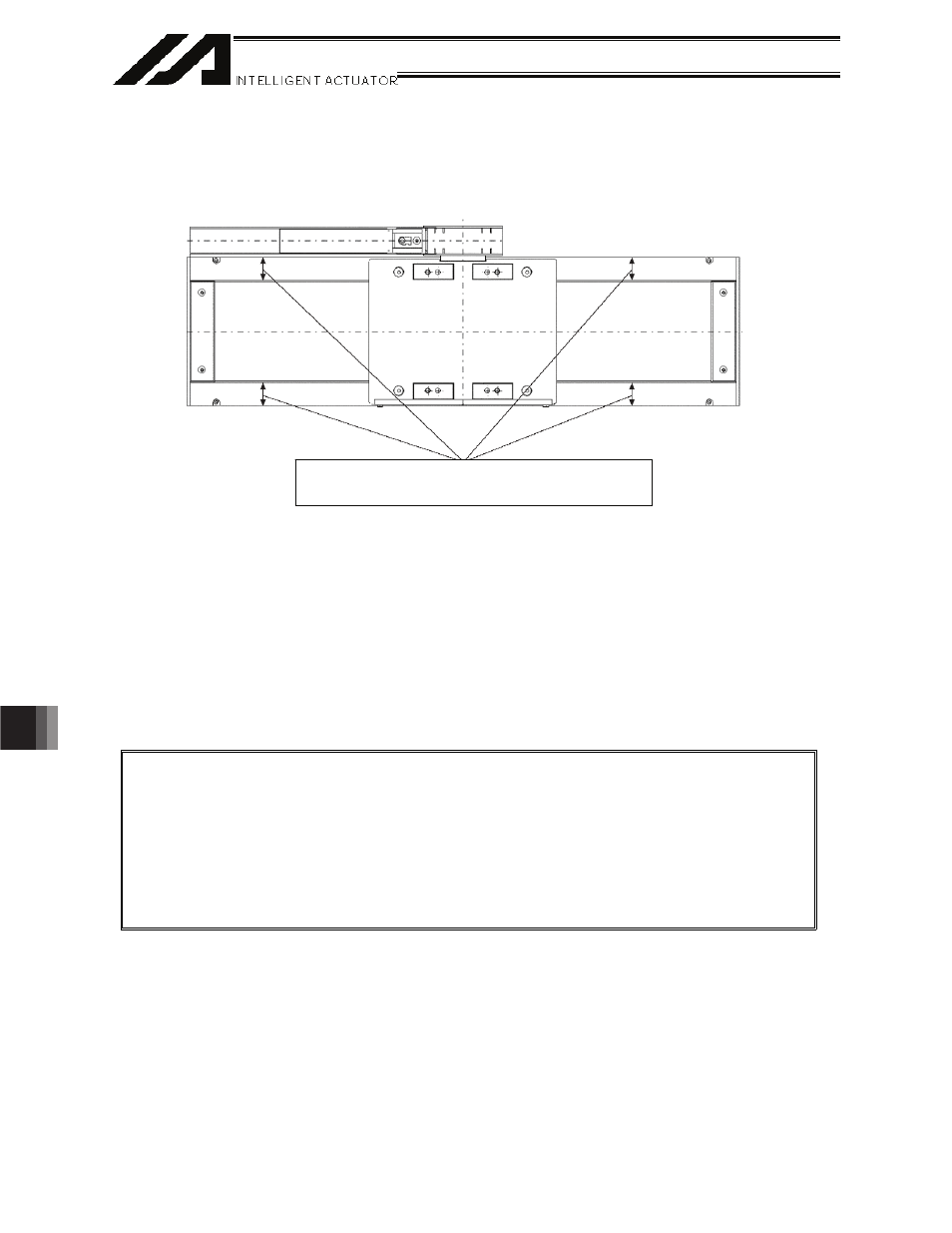

[4] Move the slider over its full stroke by hand to confirm that the dimensions on both sides of the

stainless sheet are roughly uniform, as shown below.

If not, the stainless sheet is skewed. Repeat the adjustment from step [1] to make sure the

stainless sheet extends straight.

[5] Securely tighten the stainless-sheet retainer bolts that have only been loosely tightened, and then

install the inspection cover on the side of the slider cover.

[6] After the sheet retainer plate has been securely tightened, move the slider over its full stroke by

hand to check if the dimensions on both sides of the stainless sheet change significantly or if a

sound of slider contact is heard. If any problem is found, repeat the adjustment from step [1].

This completes the replacement procedure.

Caution:

x $OZD\VXVH,$,¶VJHQXLQHVWDLQOHVVVKHHW

x During the adjustment, wear gloves or take other appropriate safety precautions to

prevent cutting hands by the stainless sheet.

x Exercise due caution not to let the permanent magnets attract magnetic

substances during the adjustment.

x Those wearing a pacemaker or any other medical device must not perform this

adjustment.

Dimensions on both sides of the stainless sheet

must be roughly uniform.