1 installing the actuator – IAI America LSAS-N15HM User Manual

Page 47

9. Installation

31

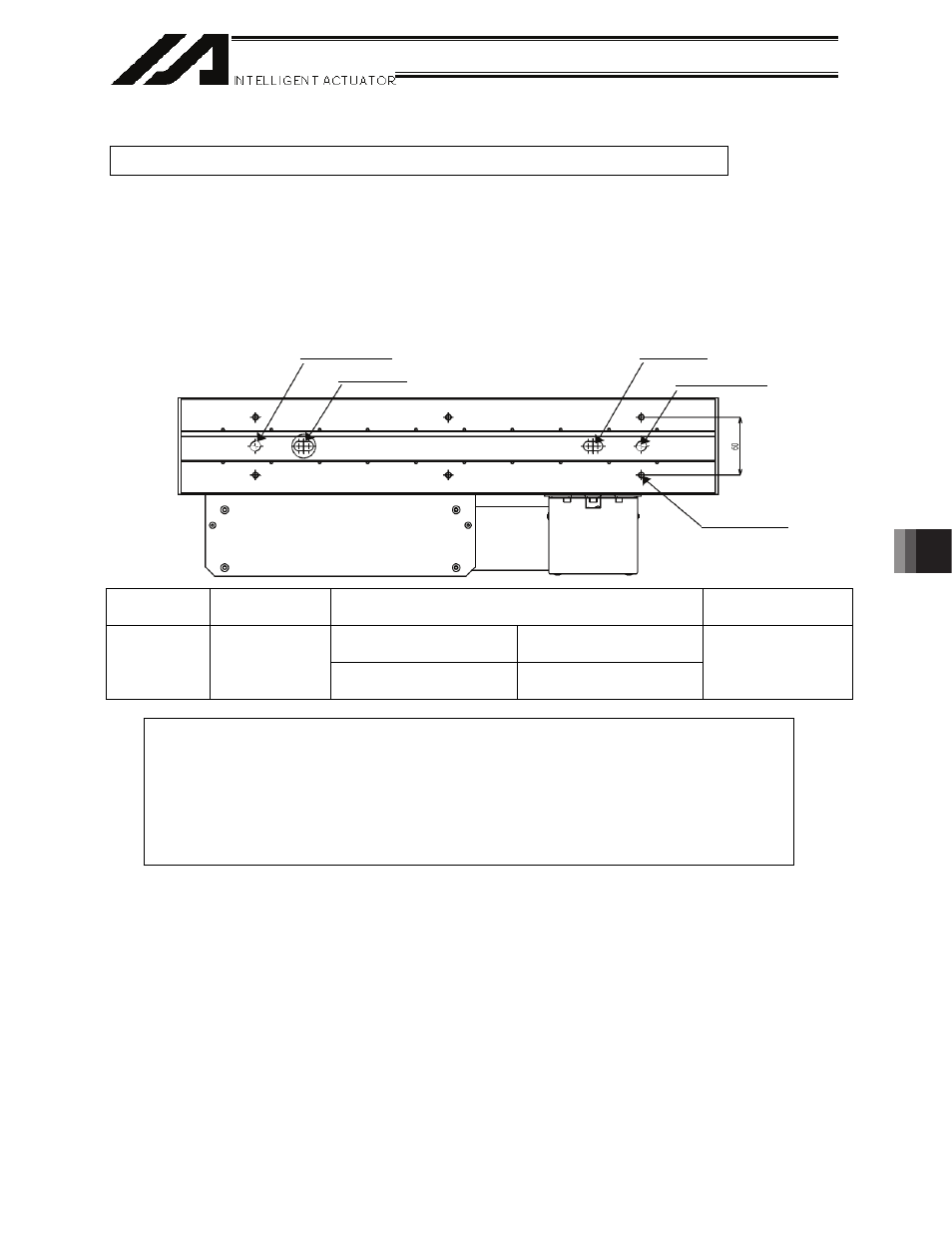

Reamed hole

Reamed hole

Long hole

Long hole

Tapped hole

9.1 Installing

the

Actuator

Install the actuator on a machined surface or other flat surface of equivalent accuracy.

9.1.1 N10SS,

N10SM

Mounting tapped holes are provided on the back of the base. Use these tapped holes for mounting the

actuator. The effective depth of the screws for mounting the base is as shown below. Because the taps

are blind holes, exercise due caution when selecting the bolt length.

If an inappropriate bolt is used, the tapped holes may be damaged and/or the mounting strength of the

actuator may become insufficient, causing the degradation of precision and/or unexpected accidents.

Additionally, the reamed holes for the positioning pins are provided on the back of the base.

Tap diameter

Effective tap

length

Tightening torque

Reamed hole

Bolt bearing surface is

steel

Bolt bearing surface is

aluminum

M6 12

mm

12.4 N

ym (1.26 kgfym) 5.36

N

ym (0.55 kgfym)

10H7 depth 8 mm

About Tightening Screws

x Use hexagonal socket head bolts for the male screws used to install the base.

x Use of high-strength bolts of ISO-10.9 or greater is recommended.

x Ensure at least the following effective thread lengths for the bolts and male screws:

Male screw is made of steel

o Same as the nominal diameter

Male screw is made of aluminum

o Twice the nominal diameter