4 inspecting the interior, 5 cleaning the interior – IAI America LSAS-N15HM User Manual

Page 62

12. Maintenance and Inspection

46

12.4 Inspecting the Interior

With the power supply turned off, turn up the stainless sheet and visually inspect the interior.

Check the following items inside the actuator.

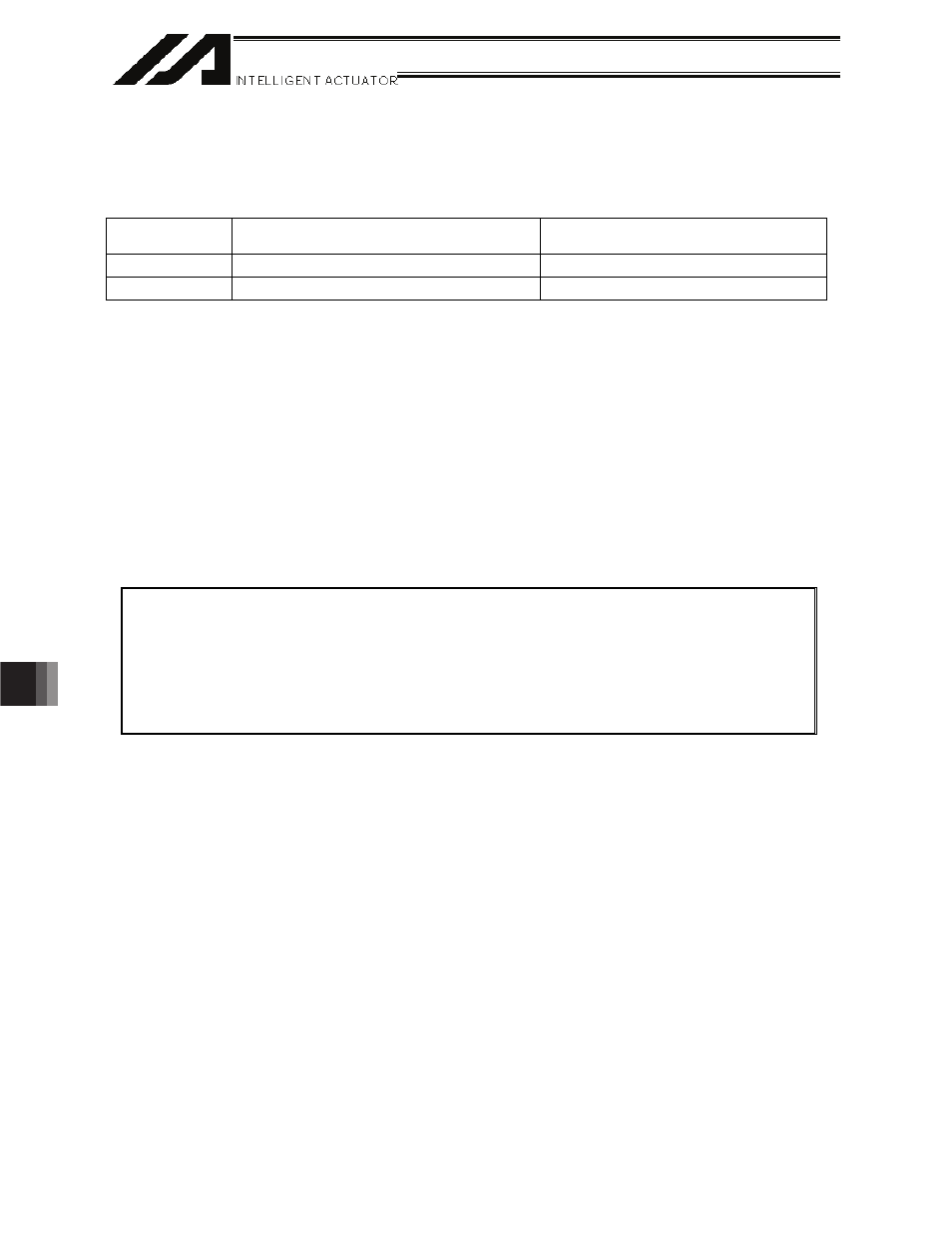

Place of

Inspection

Description of Inspection

Remarks

Actuator

Loosening of actuator mounting bolts, etc.

Guide

Lubrication condition, soiling, play

If there is any abnormality, contact IAI.

Visually check the interior condition. What you should focus are entry of dust and other foreign matters

and the lubrication condition.

Even if grease has turned brown, the actuator is lubricated properly if its traveling surface is glossy.

If grease has become dirty due to entry of dust and no longer looks glossy, or if the amount of grease has

decreased over a long period of use, clean the respective parts and then add grease.

The procedure to check the interior is specified below:

[1] Move the slider toward the home side.

[2] Remove the screws securing the sheet using a socket wrench with a width across flats of 2.5 mm.

[3] Turn up the sheet and check the interior.

[4] After the check, assemble the parts by following the same steps in the reverse order.

For more information about stainless sheet tension adjustment, see 13, "Replacement/Adjustment of

6WDLQOHVV6KHHW´

Caution: When checking the interior, do not forcibly bend or scratch the stainless sheet.

Do not pull the sheet, either, as it may change the initial installation condition.

If the installation condition changes, the sheet may become offset or reach its life

prematurely. If you have noticed any negative effect as a result of improper handling

of the sheet, please contact IA

,¶V6DOHV(QJLQHHULQJ6HFWLRQ

When working with the stainless sheet, wear gloves or take other appropriate

precautions to prevent cuts by the edges of the sheet.

12.5 Cleaning the Interior

x Wipe dirty areas using a soft cloth, etc.

x Do not blow highly compressed air onto the actuator, as it may cause dust to enter the actuator through

gaps between parts.

x Do not use petroleum-based solvent, neutral detergent or alcohol.