2 installation surface – IAI America LSAS-N15HM User Manual

Page 50

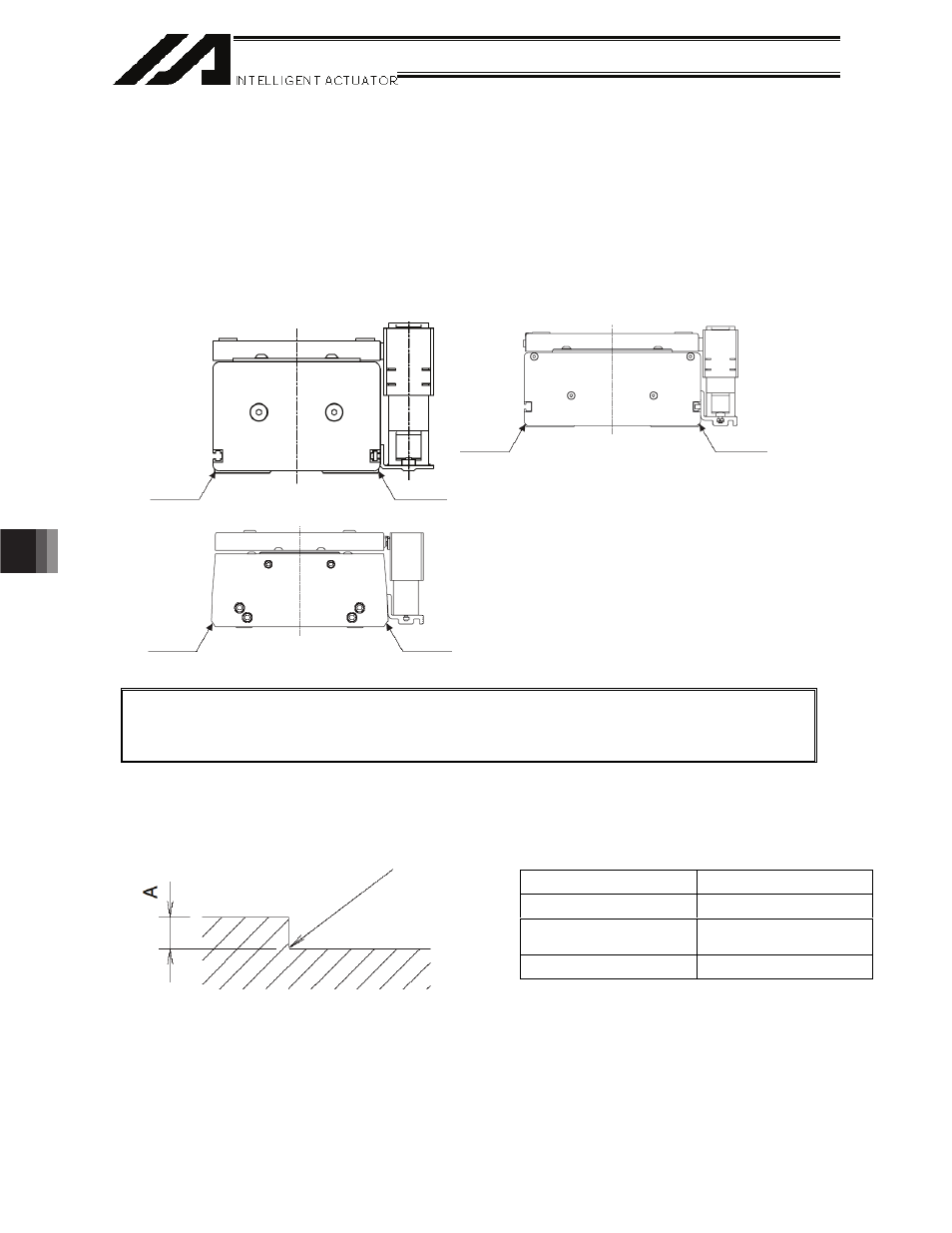

9. Installation

34

Reference

surface

Reference

surface

Reference

surface

Reference

surface

Reference

surface

Reference

surface

z166160

z1661601+61+0

z166160

9.2 Installation

Surface

x Ensure

that

the frame offers sufficient structural rigidity to prevent generation of vibration.

x Install the actuator on a machined surface or other flat surface of equivalent accuracy. The flatness of

the

installation

surface must be 0.05 mm or less.

x Provide sufficient space to allow for maintenance work.

x The

side

and bottom surfaces of the actuator base provide reference surfaces used for alignment of

slider travel.

x If you require higher traveling accuracy, install the actuator using these reference surfaces.

Caution: As shown above, each side surface of the base provides a reference surface used for

alignment of slider travel. If you require higher traveling accuracy, therefore, install the

actuator with reference to either side surface of the base.

When installing the actuator on the frame using the base reference surfaces, provide the necessary

machining by following the drawing below.

Model

Dimension A

N10SS, N10SM

2 to 3.5

N15SS, N15SM,

N15HS, N15HM

2 to 3.5

N19SS, N19SM

2.5 to 4

R0.3 or less