5 greasing, Greasing – IAI America ZR-M User Manual

Page 47

33

13.5 Greasing

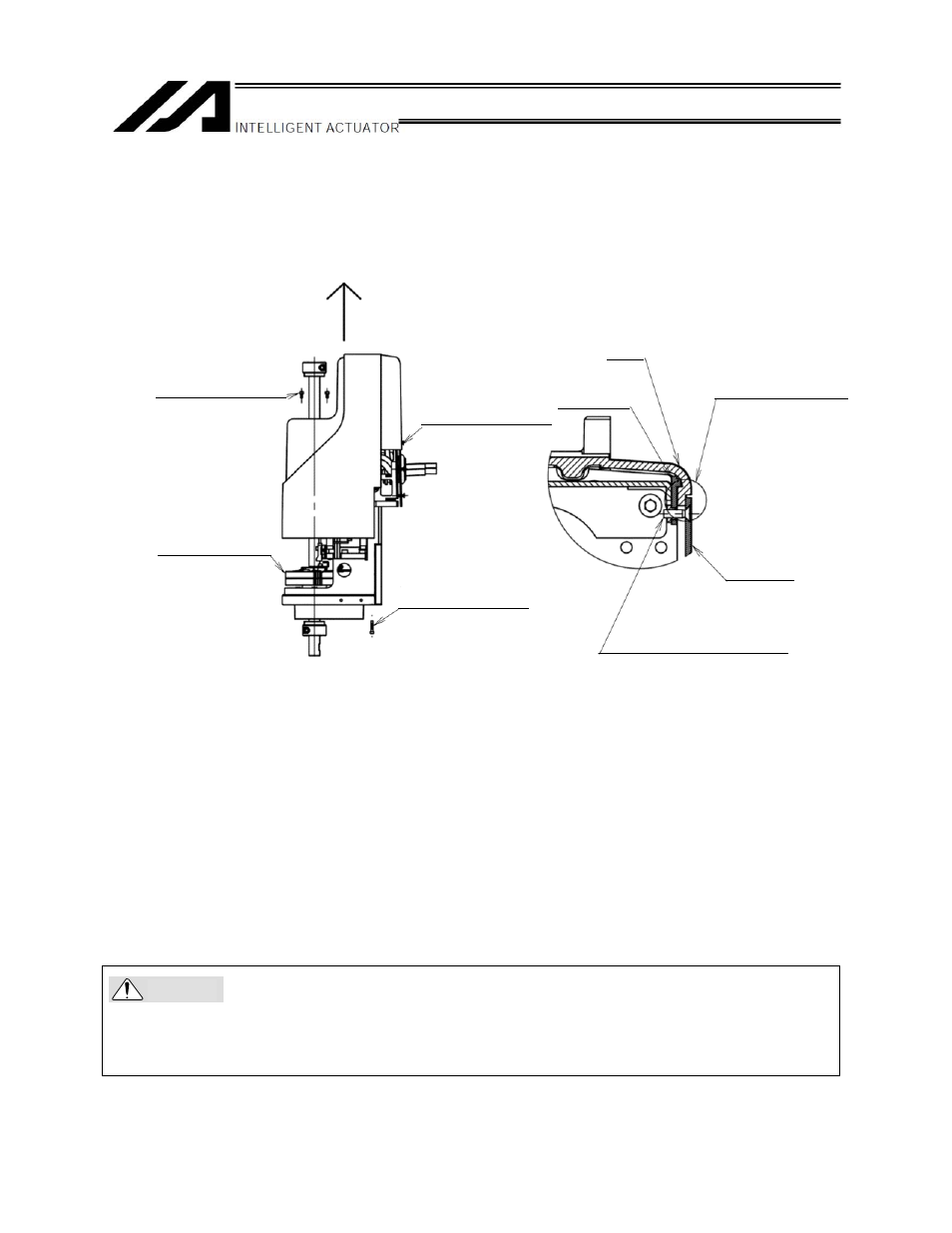

Greasing procedure for the R-axis (How to remove the cover)

Procedure

[1] Remove the hexagonal socket head bolts on the top and bottom faces.

[2] Loosen the cross-recessed countersunk head machine screws on the rear face.

[3] Shift the cover upward to remove.

[4] Apply grease on the R-axis gears.

[5] Install the cover.

* Install the cover carefully by preventing it from catching the cables on the side face.

* Install the cover so that it fits between the inner frame and rear panel.

[6] Tighten all screws.

Store the cables within the available space by paying attention not to overlap each other. Do not forcibly

secure them while the panel is still moving.

Tightening torque (M3 screw: 0.74 N

m, M4 screw: 1.76 Nm)

* The Z-axis motor may be hot. Perform this task after confirming that the Z-axis has cooled sufficiently.

Never use fluorine grease. If fluorine grease mixes with lithium grease, grease performance may be lost

and in some cases the actuator may be damaged.

Warning

Shift the cover upward.

Remove the hexagonal

socket head bolts.

M3 x 6, 4 pcs

Loosen the

cross-recessed

countersunk head

machine screws.

M3 x 10, 6 pcs

Apply grease on

the R-axis gears.

Install the cover so that

it fits between the inner

frame and rear panel.

Inner frame

Cover

Rear panel

Loosen the cross-recessed

countersunk head machine screws.

M3 x 10, 6 pcs

Remove the hexagonal

socket head bolts.

M3 x 6, 2 pcs