Maintenance and inspection, 1 inspection intervals and items, Inspection intervals and items – IAI America ZR-M User Manual

Page 45

31

13. Maintenance and Inspection

Daily and periodic inspections are needed to make sure the actuator you purchased can be used safely

and efficiently.

Perform the following maintenance and inspection items.

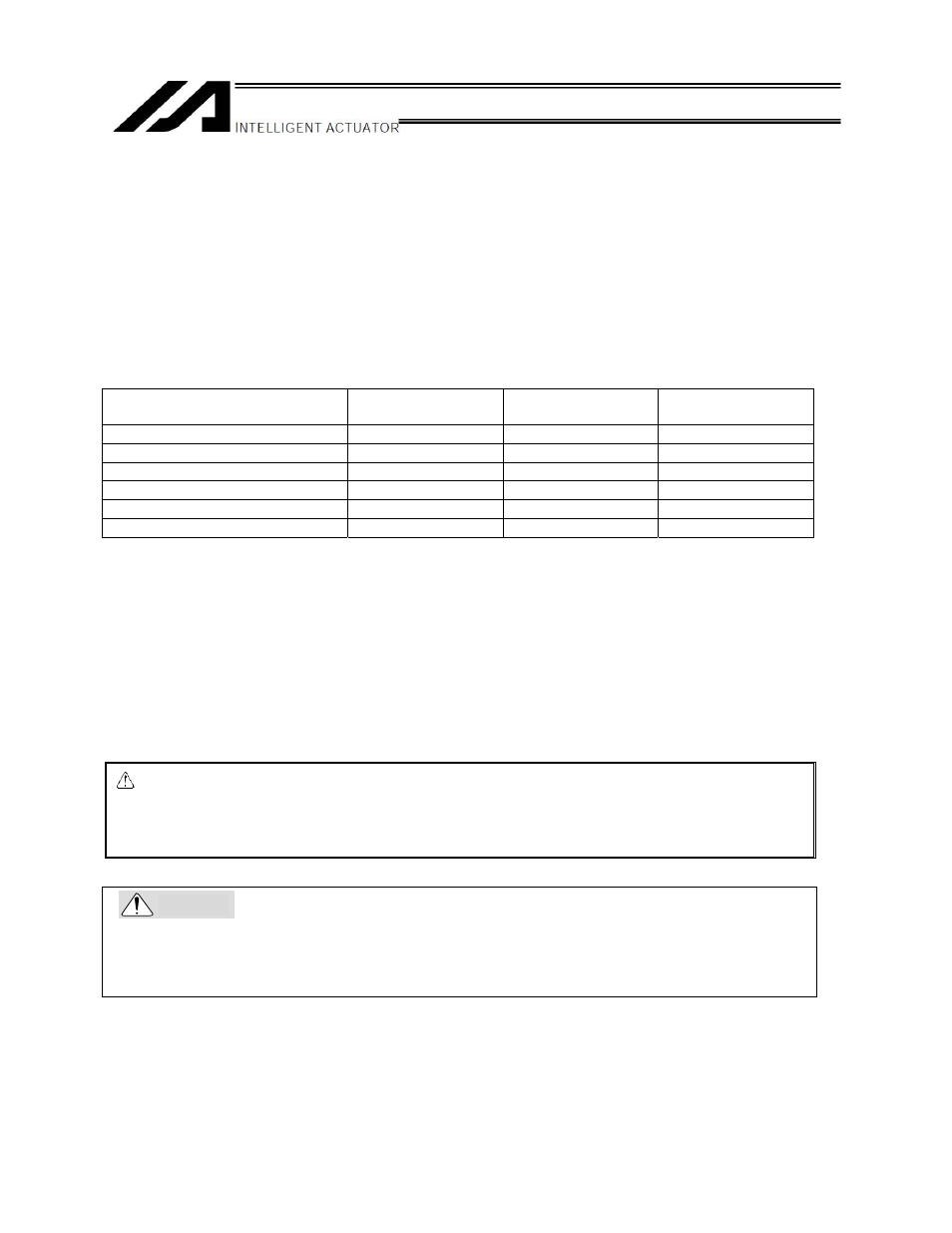

13.1 Inspection Intervals and Items

These inspection intervals assume that the actuator is operated eight hours a day. If the utilization ratio is

higher, such as when the actuator is operated continuously 24 hours a day, reduce the inspection intervals

according to the operating hours.

Visual inspection of

exterior

Inspection of

interior

Greasing

Startup inspection

1 month after start of operation

6 months after start of operation

1 year after start of operation

Every 6 months thereafter

Every year

Do not inspect, adjust, repair, replace parts or perform any other item not specified in this operating

manual.

Do not perform the following disassembly tasks or cut the cables. Any unwanted outcome resulting from

such prohibited tasks is not covered by the warranty:

Disassembly of servo motor

Disassembly of reduction gears

Disassembly of ball screw spline

Disassembly of bearing

Disassembly of brake

Cutting of cable

Caution:

Before performing any inspection, thoroughly confirm safety.

Periodic inspection may be performed with the controller power turned off or on.

In either case, put up a sign that says, “Work in progress. Do Not Enter” or the like

and disable power supply operations by other operators.

Performing inspection or maintenance work without a thorough understanding of the specific tasks

involved many result in a serious injury accident.

If inspection is not carried out regularly, the drive part may reach its life prematurely.

Warning