8 - inspection and maintenance schedule – Fulton VMP Webster Oil_Combo Burner User Manual

Page 47

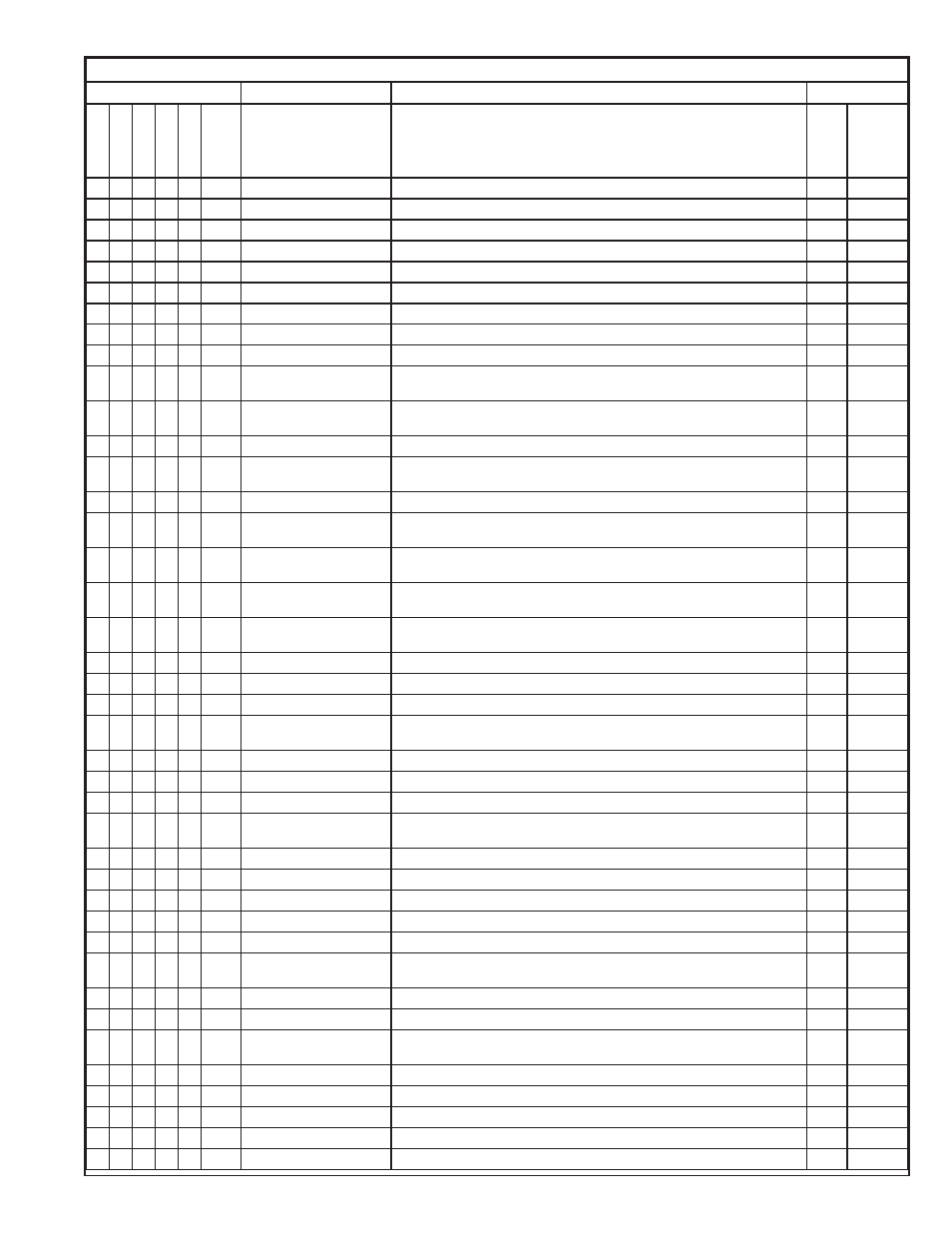

8 - Inspection and Maintenance Schedule

Frequency

Performed By

Daily

W

eekly

Monthly

Seasonal

Annual

Annual

As

Required

Component / Item

Recommended Action or Test

Boiler

Operator

Trained Burner

Technician

X

Burner Flame

Visual inspection of burner flame.

X

X

Jackshaft and Linkage

Visual inspection for smooth and free travel.

X

X

Air Damper

Visual inspection for smooth and free travel.

X

X

Fuel Metering Valves

Visual inspection for smooth and free travel.

X

X

Draft Controls (Stack)

Visual inspection for smooth and free travel.

X

X

Gas Fuel Pressure

Record in log book, compare trends.

X

X

Oil Pressure

Record in log book, compare trends.

X

X

Atomizing Air Pressure

Record in log book, compare trends.

X

X

Pilot

Visually inspect pilot flame, check and record flame signal strength if metered.

X

X

Flame SafeGuard - Pilot

Test

Close manual fuel valve on pilot during cycle and check for safety shutdown,

recording time.

X

X

Flame SafeGuard - Main

Flame

Close manual fuel valve on pilot during cycle and check for safety shutdown,

recording time.

X

X

Flame SafeGuard

Check flame safeguard components, including scanner.

X

X

Flame SafeGuard

Replace flame safeguard components in accordance with manufacturers

instructions.

X

X

X

Pilot Turndown Test

Conduct pilot turndown test annually or after any component change.

X

X

X

Hot Refractory Test

Conduct hot refractory hold in test. This test is required annually or after any

component change.

X

X

Oil Pressure and Tem-

perature Interlocks

Check oil pressure and temperature switch for smooth operation and correct

action.

X

X

Atomizing Air Pressure

Check air atomizing pressure interlock switch for smooth operation and cor-

rect action.

X

X

Interlock Controls

Check other interlocks that may be used on the burner for smooth operation

and correct action.

X

X

Firing Rate Control

Check firing rate control and verify settings.

X

X

Combustion Tuning

Conduct a combustion test, verify setting and NOx emission levels.

X

X

Pilot and Main Fuel Valves Make visual and manual check for proper sequencing of valves.

X

X

Pilot and Main Fuel Valves Check all coils, diaphragms, interlock switch & other parts of all safety shutoff

valves.

X

X

Pilot and Main Fuel Valves Perform leak tests on all safety shutdown control valves.

X

X

Low Pressure Air Switch

Test low air pressure switch for proper operation and adjustment.

X

X

Mod Damper Switch

Check damper low fire proving switch per manufacturers instructions.

X

X

Linkage and Fuel Cams

Check linkage and cams for wear and replace any items with wear indication

or stress cracks.

X

X

FGR Control Valve

Visual inspection for smooth and free travel.

X

X

FGR Control Valve

Clean and lubricate FGR control valve.

X

X

FGR Shutoff Valve

Visually inspect for smooth and complete travel.

X

X

FGR Shutoff Valve

Clean and lubricate FGR shutoff valve

X

X

FGR Condensate Drain

Open FGR condensate drains, remove all condensate.

X

X

FGR Shutoff Valve Switch

Check operation of shutoff FGR valve for full rotation and position proving

switch.

X

X

FGR Duct

Inspect and clean FGR duct.

X

X

Combustion Air Fan

Clean combustion air fan and housing

X

X X

Burner Components

Visually check the burner components for signs of cracks, deformation, slip-

page or other unusual indication.

X

X

Burner Mounting

Check burner mounting clamps and brackets for tightness.

X

X

Refractory and Seals

Check burner refractory for cracks or signs of leakage.

X

X

Oil Nozzle

Check and clean oil nozzle.

X

X

Air Compressor

Check air compressor for lubrication oil and air filter.

X

X

Air Compressor

Check air compressor relief valve operation.

X

Page 47

JB Manual

General Maintenance & Care