Fulton VMP Webster Oil_Combo Burner User Manual

Page 39

Gal start = gallons at start of the test

Measured sec = measured time of test

GPH = Gallons of oil per hour

n. If equipped with FGR, adjust the NOx level to be about

10% below any guaranteed NOx performance or if no per-

formance guarantee exists adjust the FGR to provide some

added turbulence but not high enough to impact flame sta-

bility. A balance of the FGR control valve and air damper

are required to obtain the final result, as each can impact

the other. If this is a 30 ppm system, the FGR limiting pot

should be adjusted to reduce the FGR rate for stable com-

bustion, with the FGR control valve set when firing gas. If

this is a 60 ppm system, no adjustment is necessary.

o. Modulate the burner to low fire, adjusting the O2 level as

the burner modulates.

p. Adjust the low fire input, using the fuel cam and air

damper adjustments.

q. If the burner is equipped with FGR, adjust the NOx level

according to the type of system (limiting potentiometer or

matching gas).

r. Re-adjust the midfire points for the correct O2 levels.

The linkage may need to be readjusted to obtain the correct

relationship between the fuel valve and air damper. See

Figure I-1.

s. If equipped with FGR, adjust the NOx levels at low and

midfire rates to be about 10% under the guaranteed levels

or as required for the gas firing.

t. The burner should be operating at low fire to adjust the

air proving switch. Turn the adjusting screw cw (in) until the

burner trips out (shutdown caused by the air flow switch).

Turn the adjustment screw ccw (out) 1 ½ turns from the

point of shutdown. Check the operation at higher rates.

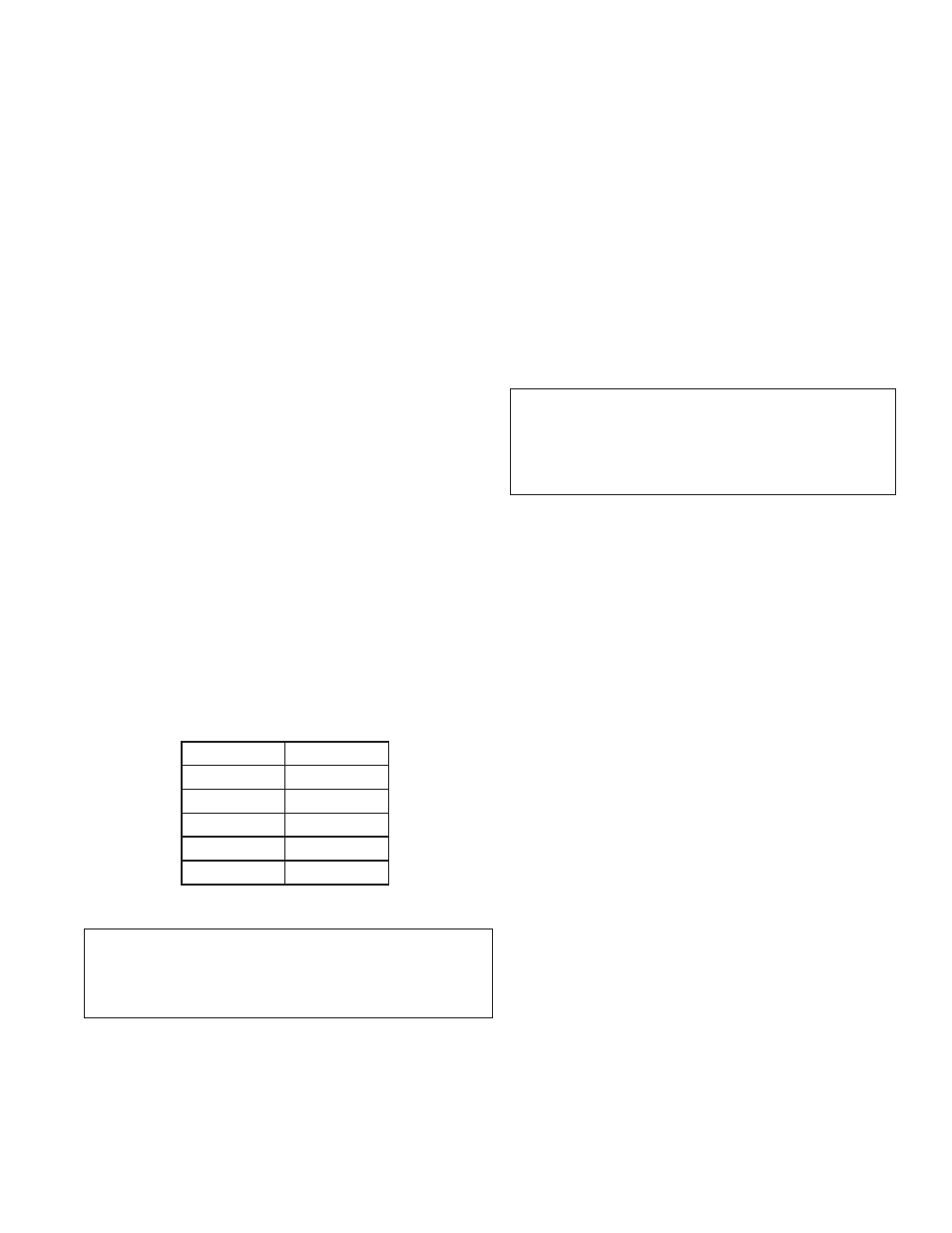

FIGURE I-4

Typical Atomizing Air Pressure

% Rate

Minimum

20

10 - 25

30

12 - 30

40

15 - 35

50

20 - 40

100

25 - 60

13. Heavy Oil Setup

CAUTION

WHEN WORKING WITH HEATED OIL, PROTEC-

TIVE CLOTHING, INCLUDING GLOVES, SHOULD BE

WORN TO PROTECT FROM BURNS.

The air atomized heavy oil system requires the additional

adjustment of oil temperature in the burner setup. The tem-

perature is adjusted to improve the viscosity for good atomi-

zation. Typically, this will be about 150

o

F for #4 oil, 180

o

F

for #5 oil and 200

o

F for # 6 oil.

a. Prior to startup, the oil system must be operating with the

oil temperature to the burner (before the trim heater) within

20

o

F of the final temperature.

b. Place the burner switch in the “OFF” position. If this

is a combination fuel burner, make sure the fuel selector

switch is on “OIL” and that the oil pump is running.

c. Place the “Auto-Manual” switch in the manual posi-

tion.

d. Place the manual flame control potentiometer in the

MIN (low fire) position.

e. Turn the electrical power on for the burner, boiler and

related components.

f. The oil may take some time to get up to temperature.

If the oil is cool, the ball valve downstream of the N.O. oil

return valve (Figure B-7) can be opened to make it easier

for the oil to circulate and reach operating temperature.

g. Verify that the oil metering valve is at the nearly closed

position.

h. Turn the burner switch to “ON”. This will start the

blower motor and initiate the prepurge cycle.

WARNING

DO NOT ATTEMPT TO START THE BURNER WHEN

EXCESS OIL HAS ACCUMULATED, WHEN THE

UNIT IS FULL OF VAPOR, OR WHEN THE COM-

BUSTION CHAMBER IS HOT.

i. When the prepurge sequence is complete and the low

fire start switch is made, the pilot valve will open and

the pilot flame should be visible through the burner sight

port.

j. When the pilot flame is established, the flame safe-

guard will energize the main oil valves (indicated with

the Fuel Valve Light), and the burner should ignite at low

fire. This operation of the main fuel valves must be visu-

ally checked by observing the valve stem moving up with

a motorized valve or hearing the clicking noise from a

solenoid valve.

k. After a few seconds, the combustion analyzer should

have an accurate reading of the O2 in the stack. The O2

level should be between 4% and 7% (See Figure I-3 for

O2 rates) and the nozzle oil press should be between 10

and 20 PSIG. Do not attempt to fine tune combustion

until the high fire input has been set.

• Turning the cam screw in will add fuel, making it richer

and reducing the O2 level.

• Turning the cam screw out will reduce the fuel input,

increasing the O2 level.

• The air damper should be positioned for the correct low

fire settings.

• The atomizing air pressure can be adjusted using the

air bleed valve (Figure I-4).

• The oil temperature can be adjusted to obtain the best

atomization.

l. Operate the burner until the boiler is warmed up and

near the operating pressure or temperature.

m. Increase the firing rate, using the manual potentiom-

eter, while monitoring and adjusting the O2 level. Adjust

the cam, oil and atomizing air pressure and oil tempera-

ture as needed to reach the high fire input.

n. At high fire (end of the modulating motor travel), ad-

just the high fire input to match the maximum input listed

on the rating label. Using a flow meter, the fuel input may

Page 39

Startup and Operating Adjustments

JB Manual