Fulton VMP Webster Oil_Combo Burner User Manual

Page 37

the highest expected gas pressure.

• With a gauge or manometer at the same location as the

high gas pressure switch, modulate the burner to deter-

mine the firing rate with the highest gas pressure.

• At the highest gas pressure, adjust the high gas pres-

sure setting down until the switch opens and causes the

burner to shutdown.

• From the scale reading of the switch, adjust the set-

ting to a pressure that is 10% higher than the shutdown

pressure. For example, if the switch opened at 10 inches

as indicated on the high gas pressure switch, the switch

should be adjusted to a reading of 11 inches.

• Remove the gauge or manometer and plug the open-

ing.

• Cycle the burner on and off to determine if the limit works

properly.

• If the limit causes nuisance shutdowns because of small

pressure changes during startup, increase the pressure

setting an additional 5%.

z. The burner should be operating at low fire to adjust

the air proving switch. Turn the adjusting screw cw (in)

until the burner trips out (shutdown caused by the air flow

switch). Turn the adjustment screw ccw (out) 1 1/2 turns

from the point of shutdown. Check the operation at higher

rates.

11. Pressure Atomized Oil Setup

The pressure atomized oil system has a limited range of

adjustment for low and high fire, dictated by the operation

of the oil nozzle. The combustion air and FGR must be

adjusted to match these rates.

If the burner is equipped with FGR, and is a linkage sys-

tem, the type of FGR control must be determined prior

to starting. If this is a dual fuel burner, the FGR rate is

determined by the NOx performance on gas. A 60 ppm

burner will operate with the same FGR rate on gas and oil.

A 30 ppm unit will use the limiting potentiometer to slightly

reduce the FGR rate on oil firing. For Oil only combustion,

the NOx level will be given on the burner detail sheet, and

should be used to set the FGR control valve.

a. Place the burner switch in the “OFF” position.

b. Place the “Auto-Manual” switch in the manual position

or low fire hold switch in the low fire position fo LO-HI-LO

operation. If this is a combination fuel burner, make sure

the fuel selector switch is on “OIL”.

c. Place the manual flame control potentiometer in the

min (low fire) position on modulation units.

d. Turn the electrical power for the burner, boiler and re-

lated components on.

e. Verify that the oil metering valve is nearly opened (the

valve will be closed at high fire).

f. Turn the burner switch on. This will start the blower mo-

tor and initiate the purge cycle.

g. When the prepurge sequence is complete and the low

fire start switch (if used) is made, the pilot valve will open

and the pilot flame should be visible through the burner

sight port.

h. When the pilot flame is established, the flame safe-

guard will energize the main oil valves (indicated with the

Fuel Valve Light), and the burner should ignite at low fire.

This operation of the main fuel valves must be visually

checked by observing the valve stem moving up with a

motorized valve or hearing the clicking noise from a sole-

noid valve.

NOTE: If the burner is not operating as indicated, follow

the troubleshooting steps to determine the problem and

corrective action.

i. The main flame may not light on the first attempt, be-

cause it must fill the oil lines before providing oil to the

nozzle. Press the reset button on the flame safeguard to

restart the burner.

WARNING

DO NOT ATTEMPT TO START THE BURNER WHEN EXCESS OIL

HAS ACCUMULATED, WHEN THE UNIT IS FULL OF VAPOR, OR

WHEN THE COMBUSTION CHAMBER IS HOT.

j. After a few seconds, the combustion analyzer should

have an accurate reading of the O2 in the stack. The O2

level should be between 4% and 7%, and the nozzle oil

pressure should be between 50 and 70 PSIG return line

pressure for the JB3. JB1 and JB2 burner low fire oil pres-

sure should be 100 psig. Do not attempt to fine tune com-

bustion until the high fire has been set.

If the burner is equipped with FGR, the FGR control valve

should be set for the approximate NOx level required.

1. Turning the cam screw in will add fuel, making it richer

and reducing the O2 level.

2. Turning the cam screw out will reduce the fuel input,

increasing the O2 level.

3. The air damper should be positioned for the correct

low fire settings.

k. Operate the burner until the boiler is warmed up, and

near the operating pressure or temperature.

l. Increase the firing rate, using the manual potentiom-

eter or put the low fire hold switch in auto position, while

monitoring and adjusting the O2 level. Adjust the cam as

needed to reach the high fire input.

If the burner is equipped with FGR, adjust the FGR control

valve as required to maintain the NOx level.

Page 37

Startup and Operating Adjustments

JB Manual

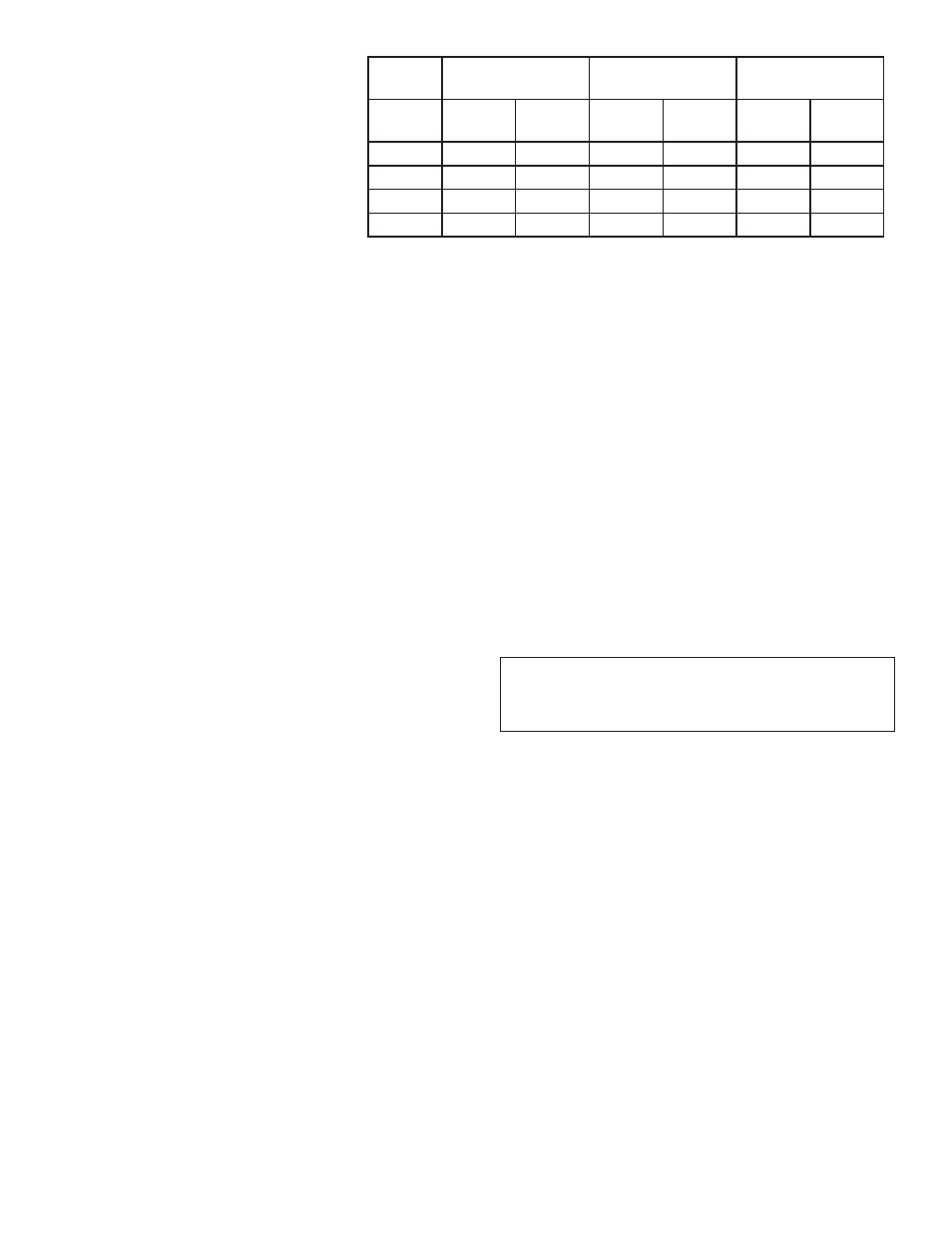

Natural Gas

With FGR

Natural Gas

No FGR

Oil

% Rate

Min

% O2

Max

% O2

Min

%O2

Max

%O2

Min

%O2

Max

%O2

30

5.0

7.0

5.0

7.0

3.5

7.5

40

4.0

7.0

4.0

7.0

3.0

7.0

50

3.0

5.0

3.0

5.0

3.0

5.0

100

3.0

5.0

3.0

5.0

3.0

5.0

Figure I-3

O2 levels