Fulton VMP Webster Oil_Combo Burner User Manual

Page 33

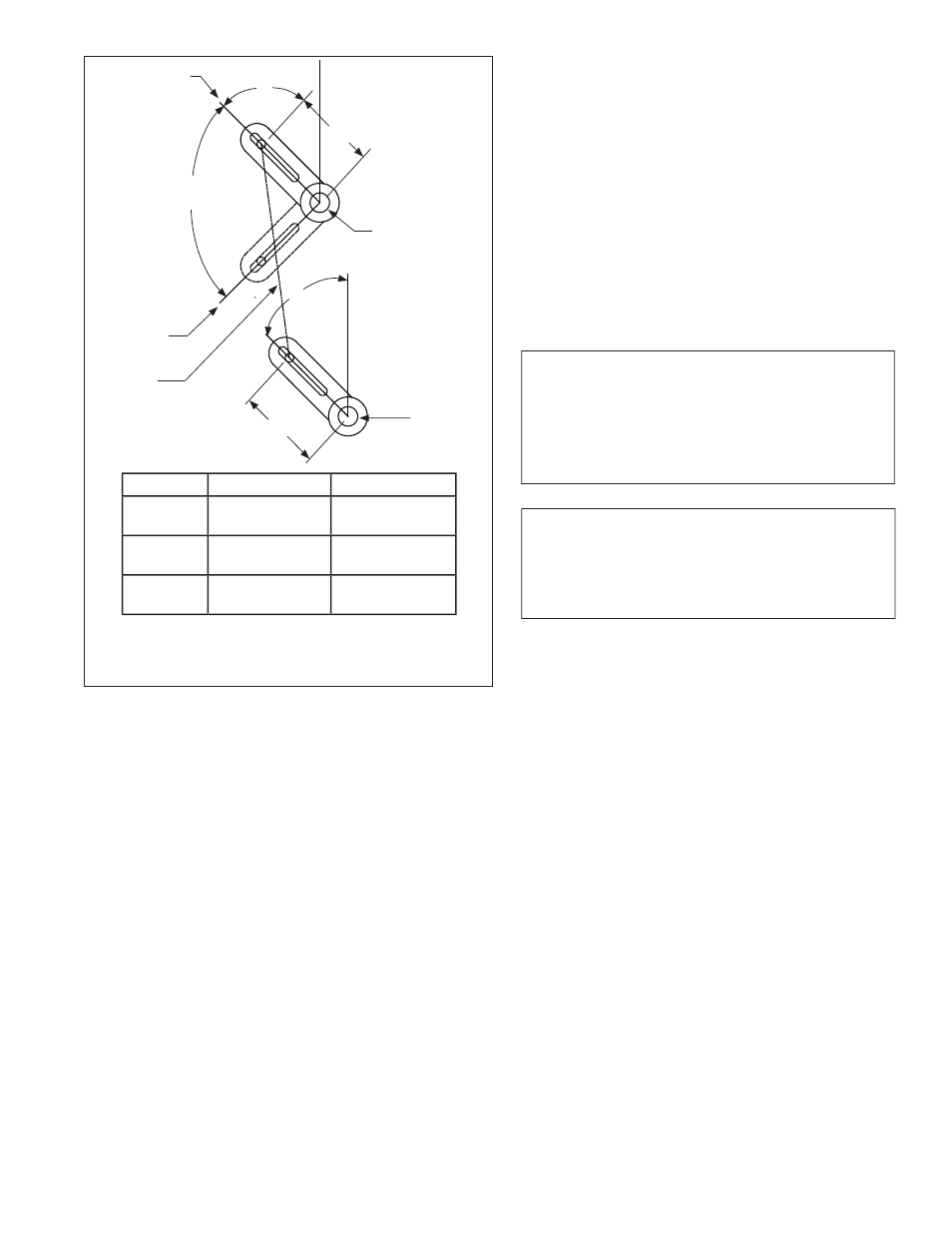

B

Low

Fire

High

Fire

Modulating

Range 90

o

A

Drive Arm

Jackshaft

Driven

Arm

D

C

Valve

(Air Damper,

FGR Valve...)

Linkage Arm

Dim

Smaller

Larger

Angle A

Slower LF driven

arm travel (D)

Faster LF driven

arm travel (D)

Length B

Reduce driven

arm travel (D)

Increase driven

arm travel (D)

Length C

Increase driven

arm travel (D)

Reduce driven

arm travel (D)

b. Decreasing the angle of the drive arm will slow the ini-

tial valve travel (and speed up the travel at high fire). This

would be done to get the air damper to match the fuel valve

action.

3. Fuel Cam Adjustments

The cam is used to adjust the intermediate fuel rate with

the low and high fire settings done by the linkage connec-

tions. The intermediate rates can be adjusted by turning the

adjusting screws in the clockwise direction to increase fuel

input and decrease the % O2 level in the flue gases. Turn-

ing the adjustment screws counterclockwise will decrease

fuel input and increase % O2 in the flue gases.

The following guidelines should be used for adjusting the

cam:

a. When adjusting the screws, the adjacent screws must

also be adjusted to provide a smooth contour from screw to

screw. When complete, the flexible strip between the adjust-

ing screws and the roller must come in contact with each

screw, providing a smooth transition from low fire to high

fire.

b. The end screws (or nuts) can be adjusted to hold the strip

against the screws, but should not deform the strip.

c. There should be no upsets in the profile, where the flex-

Figure I-1

Linkage Adjustments

ible strip is required to move to a screw position where

it is initially not in contact with the screw. Also, the

movement from one screw to the next cannot be too

large (more then 1/8”). This will cause the strip to flex

and will lead to premature failure of the strip.

d. The adjusting screws have a limited range of adjust-

ment. They can be turned in until they are flush with

the aluminum bar and adjusted out until the side wash-

ers of the roller contact the aluminum bar.

e. If any adjusting screw does not turn with some re-

sistance, the cam must be replaced.

f. When the cam adjustment is complete, the retention

plate must be installed. The retention plate will help

insure that the fuel valve position will not get far from

its ideal position, even with interference or sticky valve

operation.

WARNING

IF THE CAM ADJUSTING SCREWS DO NOT HAVE

RESISTANCE TO TURNING, THE CAM SHOULD

BE REPLACED, AS THE SCREWS MAY CHANGE

POSITION. FAILURE TO CHANGE A DEFECTIVE

CAM MAY RESULT IN INJURY OR DEATH.

CAUTION

LARGE CHANGES FROM ONE ADJUSTING

SCREW TO ANOTHER WILL RESULT IN PREMA-

TURE FAILURE OF THE CAM AND MAY PREVENT

THE BURNER FROM OPERATING PROPERLY.

g. If the contour has a sharp rise in the cam screw pro-

file, trying to open the valve very quickly in the first few

screws, the linkage should be readjusted to cause the

air damper to open slower (make the jackshaft drive

arm more parallel to the linkage rod). Likewise, the op-

posite contour can be corrected by speeding up the air

damper drive (Figure I-1). The final cam screw profile

should be close to the profile of the cam with no abrupt

changes.

4. FGR Adjustments

Flue gas is recirculated back into the burner to reduce

the flame temperature, which reduces the NOx level.

High quantities of flue gas result in lower NOx levels,

but can also result in flame instability if there is too

much FGR. Natural gas fuel can handle larger quanti-

ties of flue gas than oil and can have much lower NOx

levels as a result. Generally, the NOx levels only apply

to gas firing and oil firing is not adjusted for NOx levels.

There may be exceptions to this, and the orders details

should be reviewed to identify any special combustion

requirements.

Dual fuel units may need additional adjustments and

compensation to handle the different FGR rates be-

tween natural gas and #2 fuel oil. Units that require

gas NOx levels above about 45 ppm can operate with

the same quantity of FGR on both fuels and no addi-

tional controls or adjustments are needed. Burners

Page 33

Startup and Operating Adjustments

JB Manual