Table 4-8. control module (continued) – Micromod Micro-DCI: 53SL5100B Single Loop Controller User Manual

Page 39

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

33

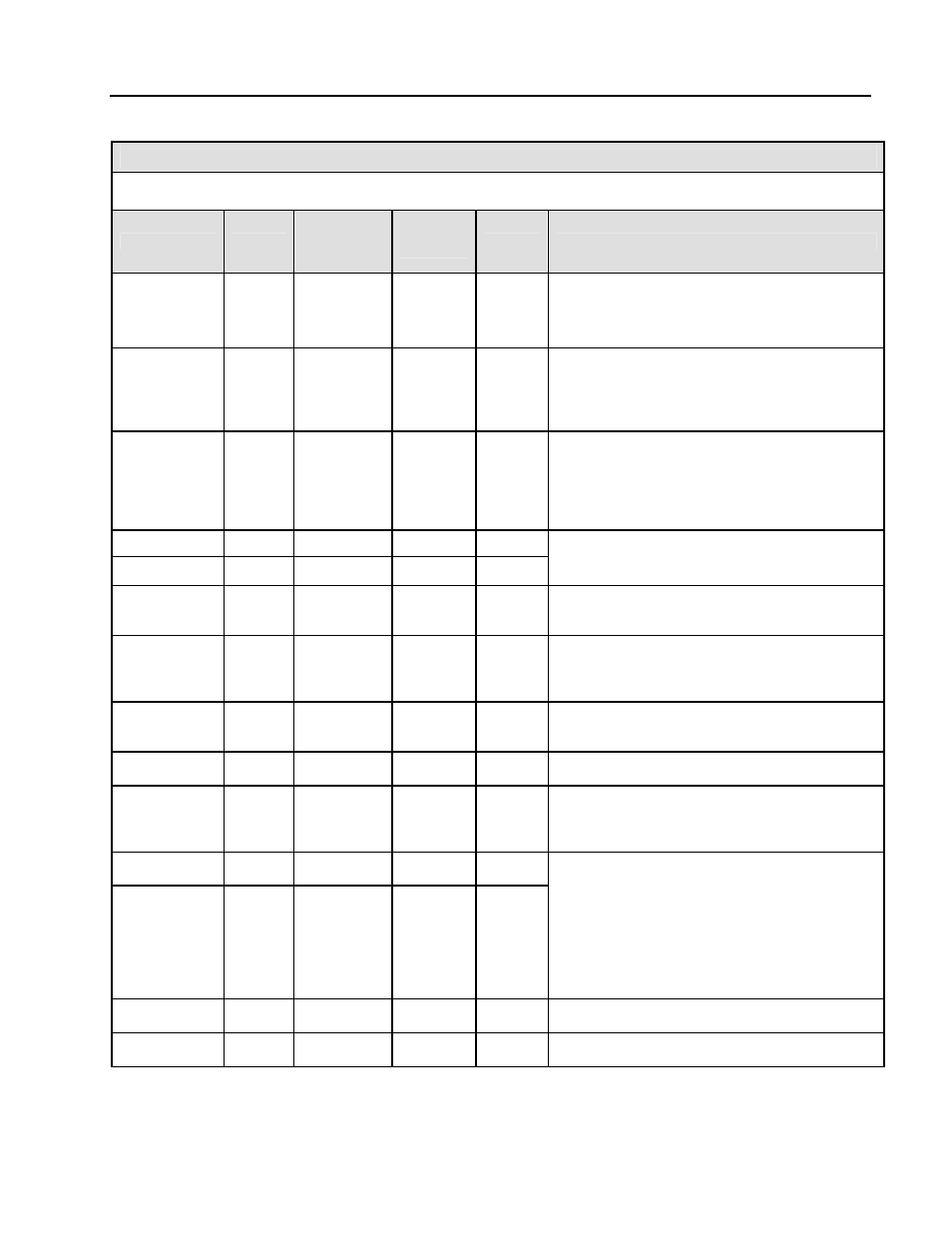

Table 4-8. Control Module (continued)

Purpose: The primary purpose of this module is to set the instrument’s Alarm Index mode, Alarm

Limits 1 & 2, and Alarm Dead Band.

Title

Symbol

CS

■

1 | 2 | 3 | 4

CON-0

Datapoint

Default

Attribute

Control Action

RSW

■

106 0

When set to a 0, the controller output increases as

the process value increases.

When set to a 1, the controller output decreases as

the process value increases.

Reverse Valve

RSV

■

L109 0

This parameter provides information for the control

display to indicate which direction the control output

must go to close the final control element. A 1

indicates that 20 mA closes the valve. A 0 indicates

that 20 mA opens the valve.

Manual

Fallback

Disable

MFD

■

L120 0

Under normal operation, whenever the controller is

powered up, the Auto/Manual Selector is forced to

the Manual position. When this datapoint is set to a

1, the selector will not be forced to the Manual

position at power up but will remain in the last

position before power was removed.

Alarm Limit 1

PL1

■

C103 100

Alarm Limit 2

PL2

■

C104 0

These parameters are the points in engineering

units at which the alarms are triggered.

Alarm

Dead

Band

ADB

■

C105 2

This parameter sets the activation/deactivation gap

for the alarm. This value in engineering units

defines an area of hysteresis at the alarm point.

Proportional

Band

PB

■

C106 100

This parameter is the percent of error required to

move the output full scale for proportional action. It

modifies the controller response in standard PID

terms.

Reset Time

TR

■

C107 0

This parameter represents the number of minutes

per repeat of integral action. It modifies the

controller response in standard PID terms.

Rate Time

TD

■

C108 0

This parameter value represents the minutes that

proportional action is advanced (derivative action).

Manual Reset

MR

■

C111 50

This parameter determines the position of the valve

(output) when the instrument is in Automatic mode

and the error is zero. (It is only in effect when TR =

0.)

Controller

Span

■

C115 1100

Controller

Lower Range

■

C116 0

These two parameters set the upper and lower

values on the controller display. They permit the

control action to be defined over a range

independent of the process variable input range.

They also determine the speed at which the

setpoint changes when the up or down arrow

pushbuttons are pressed (CS1 through CS3). For

CS4, they determine only the displayable range, as

the setpoint pushbuttons are not used.

Control Tag

Name

■

A000

An assignable 10 character name that appears with

CS1-4 displays.

Engineering

Units

■

A001 Percent

The default is PERCENT, but is assignable as units

of measure the Process Variable represents.

NOTE: CS1 = Single Loop (PID) Controller, CS2 = Analog Backup Controller, CS3 = Ratio

Controller, and CS4 = Automatic/Manual Station.