Micromod Micro-DCI: 53SL5100B Single Loop Controller User Manual

Page 111

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

105

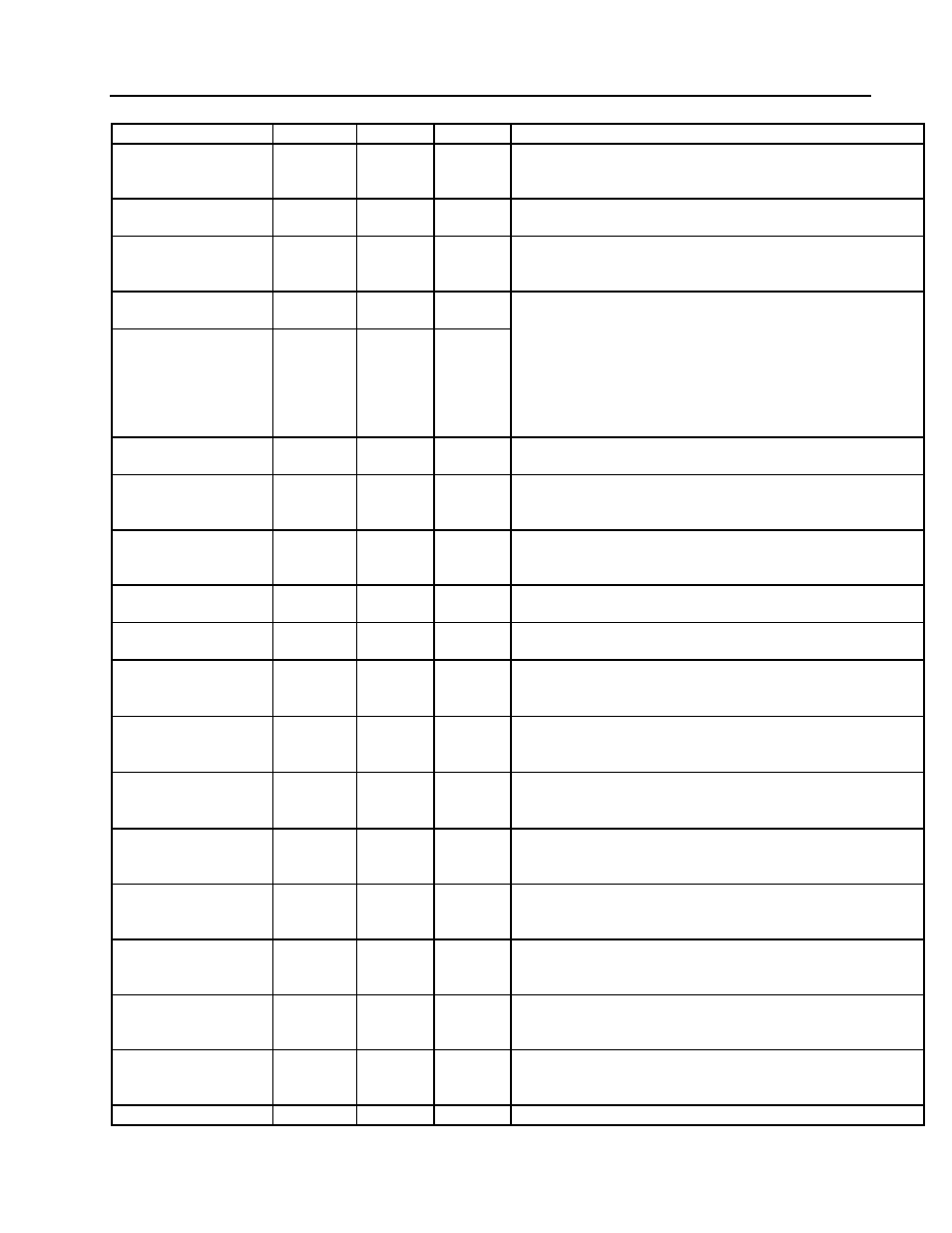

controller response in standard PID terms.

Reset Time

TR

C107

0

number of minutes per

This parameter represents the

repeat for integral action. It modifies the controller

response in standard PID terms.

Rate Time

TD

C108

0

utes that proportional

This parameter represents the min

action is advanced (derivative action).

Manual Reset

MR

C111

50

mode and

This parameter determines the position of the valve

(output) when the instrument is in Automatic

the error is zero. (It is only in effect when TR = 0.)

Controller Span

IR

C115

100

Controller Lower

Range

ues

it the control action to

e the speed at

row

ILR

C116

0

These two parameters set the upper and lower val

on the controller display. They perm

be defined over a range independent of the process

variable input range. They also determin

which the setpoint changes when the U

P

or D

OWN

ar

pushbuttons are pressed (CS1 through CS3). For CS4,

they determine only the displayable range, as the

setpoint pushbuttons are not used.

Remote Setpoint

RSP

C120

0

e.

It is the calculated result of the remote setpoint algorithm

and is used as the setpoint if the controller is in remot

ANI0 Engineering

Span

SPAN

C256

100

This determines the upper range that analog input 0

represents in engineering units. The upper range value

equals Engineering Zero plus Engineering Span.

ANI1 Engineering

Span

SPAN

C257

100

1

pper range value

This determines the upper range that analog input

represents in engineering units. The u

equals Engineering Zero plus Engineering Span.

ANI0 Engineering

ZERO

C276

0

Zero

This is the lower range value of analog input 0.

ANI1 Engineering

Zero

ZERO

C277

0

This is the lower range value of analog input 1.

ANI0 Calibrate Span

er is

CIS

C296

This is the calibration span adjustment. This paramet

factory set and should not need adjustment under

normal operation. See Section 12.3 for adjustment.

ANI1 Calibrate Span

meter is

factory set and should not need adjustment under

t.

CIS

C297

This is the calibration span adjustment. This para

normal operation. See Section 12.3 for adjustmen

ANO0 Calibrate

COS

C300

This is the calibration span adjustment. This parameter is

Span

factory set and should not need adjustment under

normal operation. See Section 12.3 for adjustment.

Parameter Point 1

PDA

F087

C106

value

d

Designator

A database datapoint whose contents will be displaye

under the Point 1 Name (e.g., C103 to display the Alarm

Limit 1 setting) of the parameter display.

Parameter Point 2

PDB

F088

C107

value

d

Designator

A database datapoint whose contents will be displaye

under the Point 2 Name (e.g., C104 to display the Alarm

Limit 2 setting) of the parameter display.

Parameter Point 3

PDC

F089

C108

d

Designator

value

A database datapoint whose contents will be displaye

under the Point 3 Name (e.g., C105 to display the Alarm

Dead Band) of the parameter display.

ANI0 Input (Display

ANI

H000

0

measured

Only)

This is the value in engineering units of the

input for ANI0 after all signal conditioning has been

applied.

ANI1 Input (Display

ANI

H001

0

measured

Only)

This is the value in engineering units of the

input for ANI1 after all signal conditioning has been

applied.

CCI Input (Display

CCI

L000

0

0 when IINV = 0.

When open, a 4 - 24 V dc input signal =