3 front panel, 1 display, Front panel – Micromod Micro-DCI: 53SL5100B Single Loop Controller User Manual

Page 21: Isplay

53SL5100B Single-Loop Controller

INSTRUCTION MANUAL

15

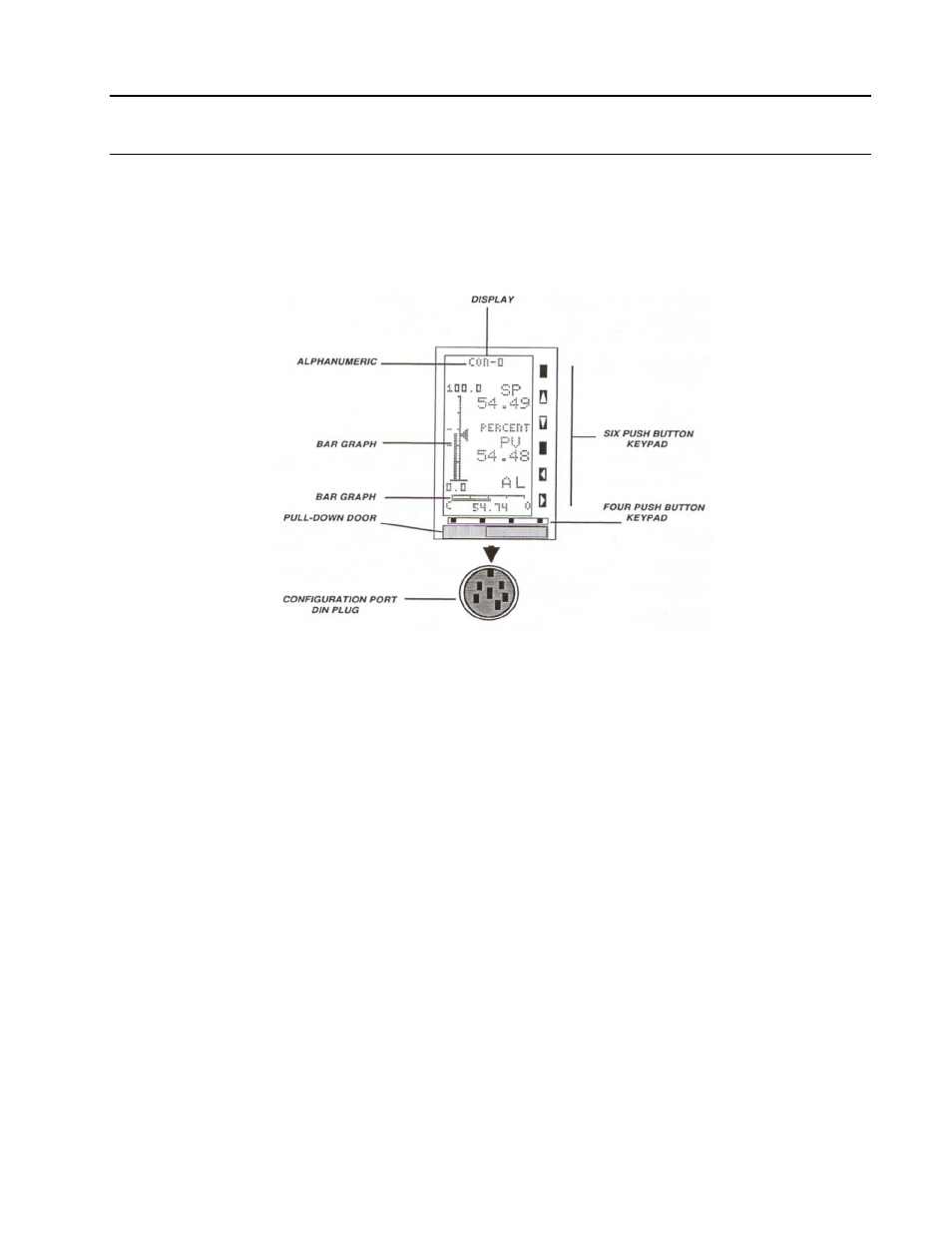

3 FRONT PANEL

The front panel of the instrument contains the display and all push buttons used to change display

presentations and parameters. The front panel has a gas discharge 96 X 48 dot matrix display, a six

pushbutton vertical keypad, and a four pushbutton horizontal keypad. It also has a configuration port DIN

plug, which is concealed behind the identification tag pull-down door. To open this door, press on the lower

front edge. Front panel display information is presented as bar graphs with associated alphanumerics or as

alphanumeric only. (See Figure 3-1.)

Figure 3-1. Front Panel

3.1 Display

The bar graph display is a visual indication of the process events monitored and subsequently altered either

by the instrument or other device. This instrument provides three unique bar graph displays and one

alphanumeric parameter display. Bar graph response dynamics as well as the alphanumerics on all of the

display types are selected when the instrument is configured.

There are four configurable operating modes, called control strategies (CS1-4). The control strategies are:

CS1, Single Loop PID Controller

CS2, Analog Backup Controller

CS3, Ratio Controller

CS4, Automatic/Manual Station

Two of the control strategies, CS1 and CS2, have identical bar graph presentations; that is why there are

three, rather than four, unique bar graph types. Each control strategy (CS1 - CS4) also has a pushbutton

selectable parameter display. Although the contents of the parameter display are selectable configuration

items, the display format is identical for each of the four control strategies.

Any display type can have a portion of its contents overlaid with an ALARM indicator. If the instrument is

manually set to engineering mode, the display can be overlaid with the CONFIGURATION or DISPLAY data

entry line. Alarm indicators warn of variation changes that exceed tolerance limits; the process may require

immediate attention. The engineering mode (EMODE) overlay provides a single entry line for data display and

alteration.