2 troubleshooting – Controlled Products Systems Group 6050-080 User Manual

Page 48

Page 38

Have a good VOM meter to check voltages and continuity. A Meg-Ohm meter capable of checking

up to 500 meg-ohms of resistance is necessary to properly check the integrity of the ground loops.

When a malfunction occurs, isolate the problem to one of three areas: 1) the operator, 2) the loop

system, 3) the keying devices. Use caution when checking high voltage areas: terminals 1

through 6, the motor capacitor and the motor.

1. Check the input indicator LEDs. They should only come ON when a keying device (card

reader, push button, etc.) is activated. If any of the input LEDs are ON continuously, this

will cause the gate operator to hold open. Disconnect the keying devices one at a time

until the LED goes OFF.

2. Check any external secondary entrapment protection devices. Any short or malfunction

in these devices can cause the gate operator to stop or to hold open.

3. A malfunction in a loop or loop detector can cause the gate operator to hold open, or to

not detect a vehicle when it is present over the loop. Pull the loop detector circuit boards

from the loop ports on the operator circuit board. If the malfunction persist, the problem

is not with the loop system. For more information on trouble shooting loops and loop

detectors, refer to your loop detector instruction sheet and to the DoorKing Loop and

Loop Detector Information Manual.

4. Check to be sure that there are no shorted or open control wires from the keying devices

to the gate operator. If a keying device fails to open the gate, momentarily jumper across

terminals 11 and 20 on the gate operator circuit board. If the gate operator starts, this

indicates that a problem exist with the keying device and is not with the gate operator.

5. If a three-button control station (open-close-stop) is connected to this gate operator,

check for proper wiring. Only a DoorKing three button control station (P/N 1200-006) can

be used with this gate operator. Others will cause a malfunction.

6. Check the high voltage supply. A voltage drop on the supply line (usually caused by

using too small supply voltage wires) will cause the operator to malfunction. Refer to the

wire size chart in section 2.1.

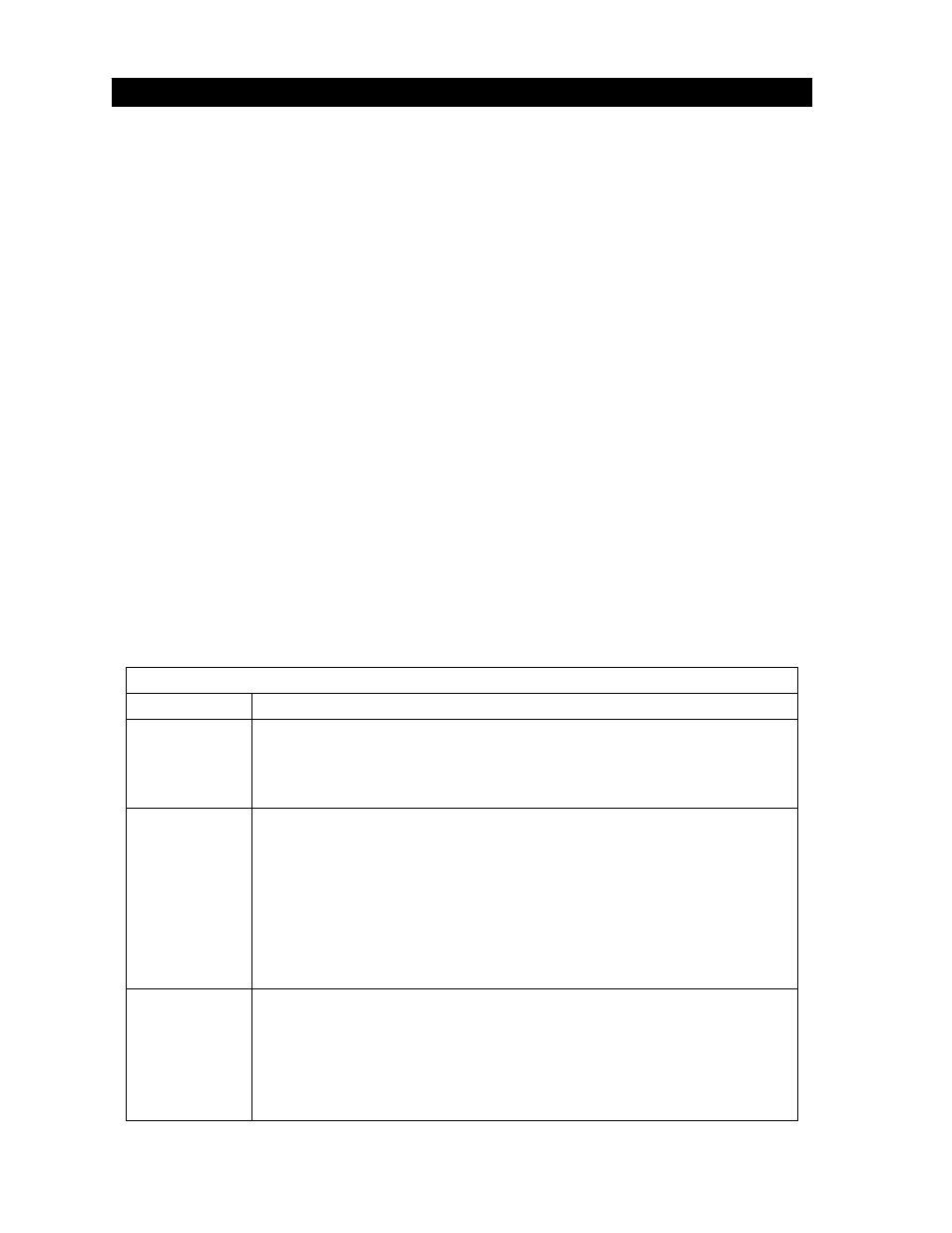

5.2 TROUBLESHOOTING

TROUBLESHOOTING

SYMPTON POSSIBLE

SOLUTION(S)

Operator will not

run. Power LED is

OFF.

•

Check that power to the operator is turned ON.

•

Transformer may be overheated. Turn power off and allow board to cool for several

minutes then retest. Check for low 115 VAC power and low voltage shorts.

•

Check for 115 VAC at terminals 2 and 3. If voltage measures OK, check the terminal strip

or replace the circuit board.

Operator will not

run. Power LED is

ON.

•

Momentarily jumper terminal 11 to terminal 20. If the input LED does not come ON, check

the terminal strip or replace the circuit board. If LED does come ON, proceed to next

steps.

•

Remove circuit board. With power ON, momentarily jumper terminal 3 to terminal 4 with a

14 AWG insulated jumper wire. CAUTION – HIGH VOLTAGE. The motor should run.

•

With power ON, momentarily jumper terminal 3 to terminal 5 with a 14 AWG insulated

jumper wire. CAUTION – HIGH VOLTAGE. The motor should run in the opposite

direction of the above step.

•

If the motor runs in both steps above, replace the control board. If the motor does not run,

or runs in only one direction, problem can be a bad motor, motor capacitor, wire

connections from the control board to the motor or a bad control board.

Slave operator

motor will not run.

•

Check that SW-2, switch 2 is ON.

•

Remove circuit board. Momentarily jumper terminal 3 to one of the slave motor terminals,

then to the other slave motor terminal with a 14 AWG insulated jumper wire. CAUTION –

HIGH VOLTAGE. The slave motor should run one way, then the other way as power is

applied to each terminal.

•

If the slave motor runs in both directions, replace the control board. If slave motor does

not run, or runs in only one direction, problem can be in the wiring from the master to slave

operator, bad slave motor or motor capacitor.