CONTREX MLP-Drive User Manual

Page 75

3 - 37

Follower Mode Analog Setpoint Example

The following example demonstrates Follower mode scaling using analog setpoint:

A pump delivers 20.0 gallons per minute of ingredient A when the pump

motor rotates at 1750 RPM. A second pump delivers 60.0 gallons per

minute of ingredient B when the pump motor rotates at 1750 RPM. A

potentiometer connected to the analog input of the MLP-Drive produces

a 10.0 volt signal when the pump B and pump A motors rotate at 1750

RPM. The lead motor A has an encoder feedback of 1000 PPR. The

feedback motor is equipped with a 60 tooth ring kit sensor. The

Follower Setpoint 1 is to reflect the flow ratio in gallons/minute of

ingredient B to ingredient A.

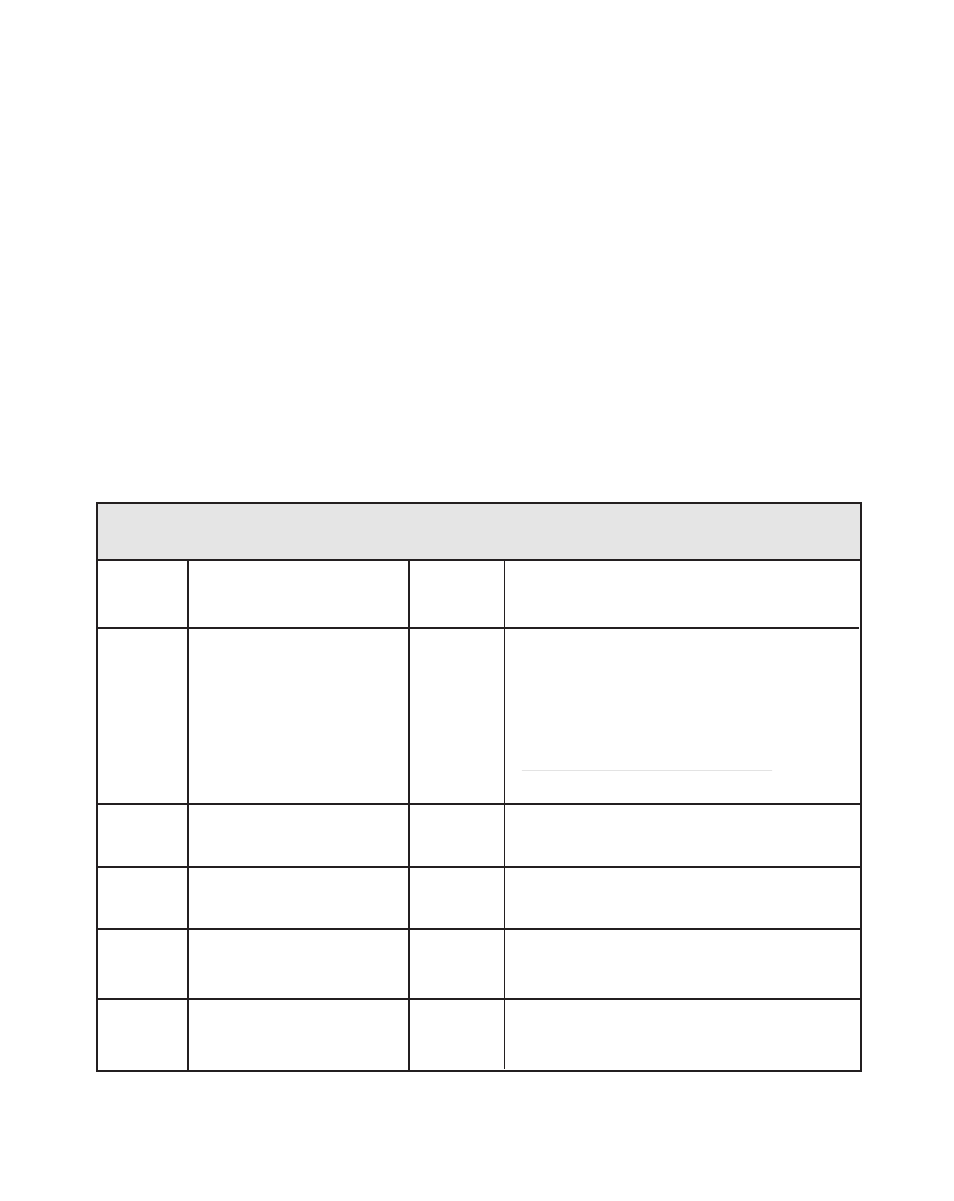

Table 3-27 Follower Mode Setpoint Allocation

CP

Parameter Name Value Remarks

CP-84

Analog Input

Allocation

CP-21

Follower

Engineering Units

CP-34

Max RPM Feedback

CP-31

PPR Feedback

CP-33

Max RPM Lead

CP-30

PPR Lead

Allocates the analog input as the

Follower Setpoint 1.

This is the Engineering Unit value

that is present if the analog input

were at 10.0 volts and the lead and

feedback at max RPM.

60.0 gal/min (ingredient B) = 3.000

20.0 gal/min (ingredient A)

The maximum operating RPM of

the feedback shaft.

The resolution of the feedback

sensor.

The maximum operating RPM of

the lead shaft.

The resolution of the lead

sensor.

6

3.000

1750

60

1750

1000