Installation, Important installation recommendations – GF Signet 2450 Pressure Sensor User Manual

Page 2

2

2450 Pressure Sensor

3. Installation

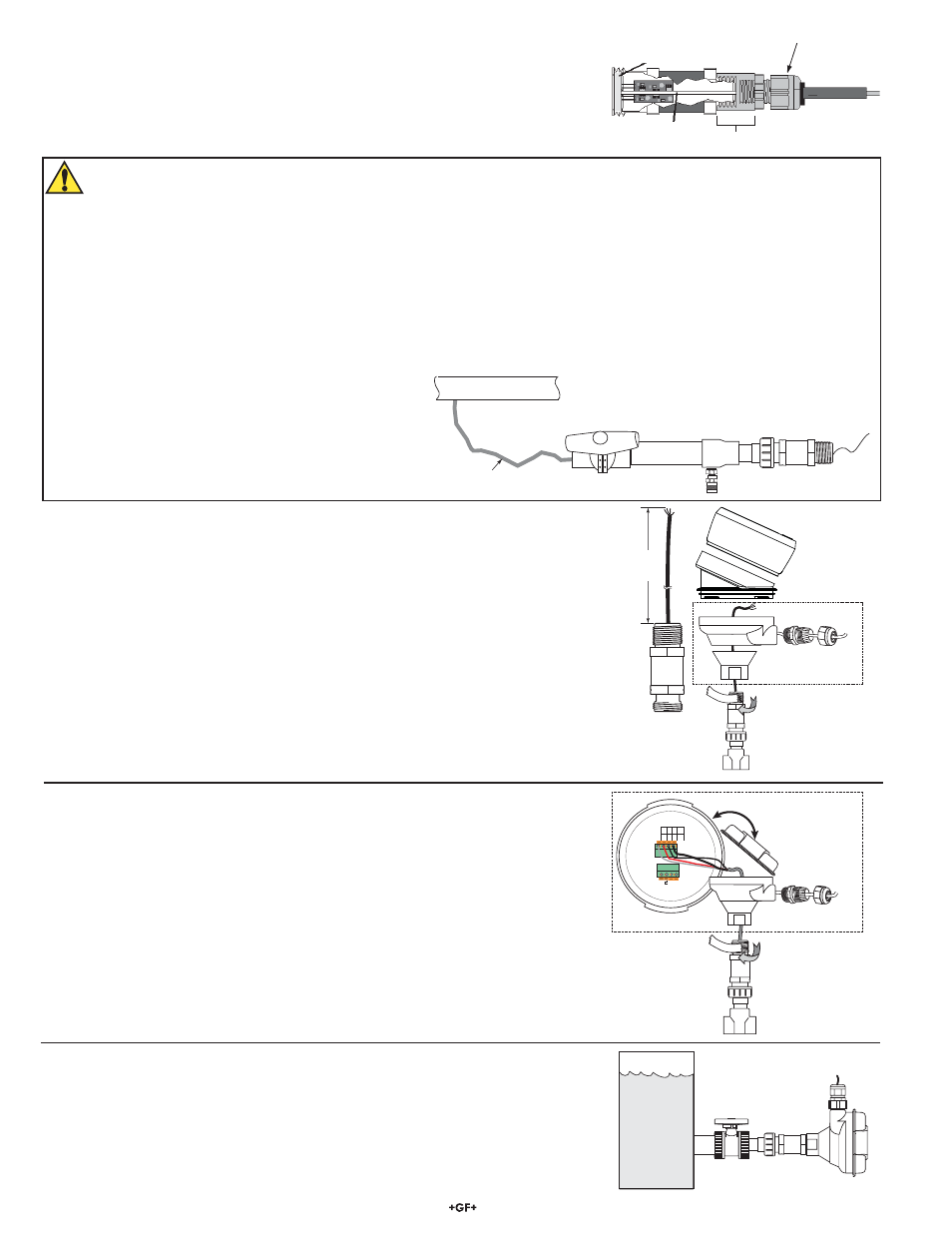

Diaphragm

Capillary Tube

Cable gland

Reducer coupling

• Signet 2450 Pressure Sensors are gauge pressure sensors. Gauge pressure sensors

measure the difference in pressure between the process on one side of a diaphragm

and the atmospheric pressure on the opposite side of the diaphragm. A tiny capillary

tube inside the sensor body is used to ensure that the back of the diaphragm remains at

atmospheric pressure. If moisture is allowed to propagate down this tube to the rear of

the diaphragm, the sensor may be damaged.

Important Installation Recommendations

• The ceramic diaphragm is subject to breakage by over-pressure conditions or mechanical contact.

HANDLE WITH CARE. Do not attempt to test the sensor by pressing on the diaphragm.

• Short duration pressure pulses or shocks, called ‘‘water hammer,’’ are generated by a rapid change in fl ow rate caused by the

operation of system components such as compressors, pumps, pistons and valves. Water hammer can reach pressure levels

far exceeding the over pressure rating of our pressure sensors and damage the ceramic diaphragm.

• A pressure snubber is a device for slowing the rate of change of system fl ow. Installation of a properly sized snubber at or

near the input of a pressure sensor will protect it from water hammer damage. Snubbers are available through plumbing and

instrumentation dealers.

• When threading the sensor into a piping system, any backpressure can damage the ceramic diaphragm.

Open nearby valves to relieve any backpressure while threading the sensor into the pipe.

• If the nearby valves cannot be open while threading the

sensor into the pipe, a bleed valve can be installed to

avoid overpressure.

• Make sure there are no air bubbles in the pipe,

particularly if a long and fl exible hose is used to tap

into the process pipe. Air bubbles could cause reading

fl uctuation and errors.

Main Valve Closed

Bleed Valve Open

Process Pipe

No Air Bubbles

Fle

xib

le h

ose

3.3 Tank Installation Options

Submersible:

• Refer to the GF product 3-2250-XX for submersible installations.

Side Tank Mount:

• Install GF ball valve to allow isolation of the sensor for maintenance.

• It is recommended that a 3-8052-1 kit be used to protect the back end of the sensor.

WARNING:

Exposing the sensor body to elevated temperatures that are different than

the tank fl uid temperatures will cause inaccurate reading.

4-20

mA

FREQ/

DA

T

A

WHT

W

HT

BLU

B

LK

N/C

R

ED

SHIELD

SENSOR

INPUT

SHIELD

–

+

FREQ/

DA

T

A

3-8052-1

Integral junction box,

3/4 in. NPT

152 mm

(6 in.)

Figure 1

Figure 2

3.1 Integral Assembly Sensor Modifi cation

• Modify sensor part number 3-2450 per fi gure 1.

• Apply sealant or PTFE tape to the process connection threads per fi gure 2, after

inspecting threads to ensure integrity. Do not install a sensor with damaged threads.

• Thread the sensor into the 3-8052 mounting kit.

• Tighten the sensor 1½ turns past fi nger tight into the process connection.

• Install 8450 transmitter (refer to 8450 manual for wiring info) or 9900 Transmitter with

Angle Adjustment Adapter (refer to 9900 manual for information).

• The 3-8052 Integral kit includes:

• 3-9000.392-1 liquid tight connector, ½ in. NPT

• Conduit base to attach 8450.

3.2 In-line Remote Assembly

The optional 3-8052-1 Integral Junction box with ¾ in. process connection offers a

convenient terminal point to extend the 2450 cable over a distance greater than 4.6 m (15 ft).

• The kit includes:

• Conduit base and cap with junction terminals

• 3-9000.392-1 liquid tight connector, ½ in. NPT

To extend the wires longer than 4.6 m (15 ft):

• Modify sensor 3-2450 as described in fi gure 1.

• Terminate the three wires to the terminal board located in the cap assembly.

• Add customer supplied wire to extend the cable.

• Terminate to the transmitter or the 4 to 20 mA input device.

• Apply sealant or PTFE tape to the process connection threads per fi gure 3, after

inspecting threads to ensure integrity. Do not install a sensor with damaged threads.

• Tighten the sensor 1½ turns past fi nger tight into the process connection.

Figure 3

3-9900

3-8450

3-8052

Integral mount kit

3-9900.396

Angle Adjustment Adapter Kit