GF Signet 3719 pH_ORP Wet-Tap User Manual

Page 6

6

Signet 3719 pH/ORP Wet-Tap

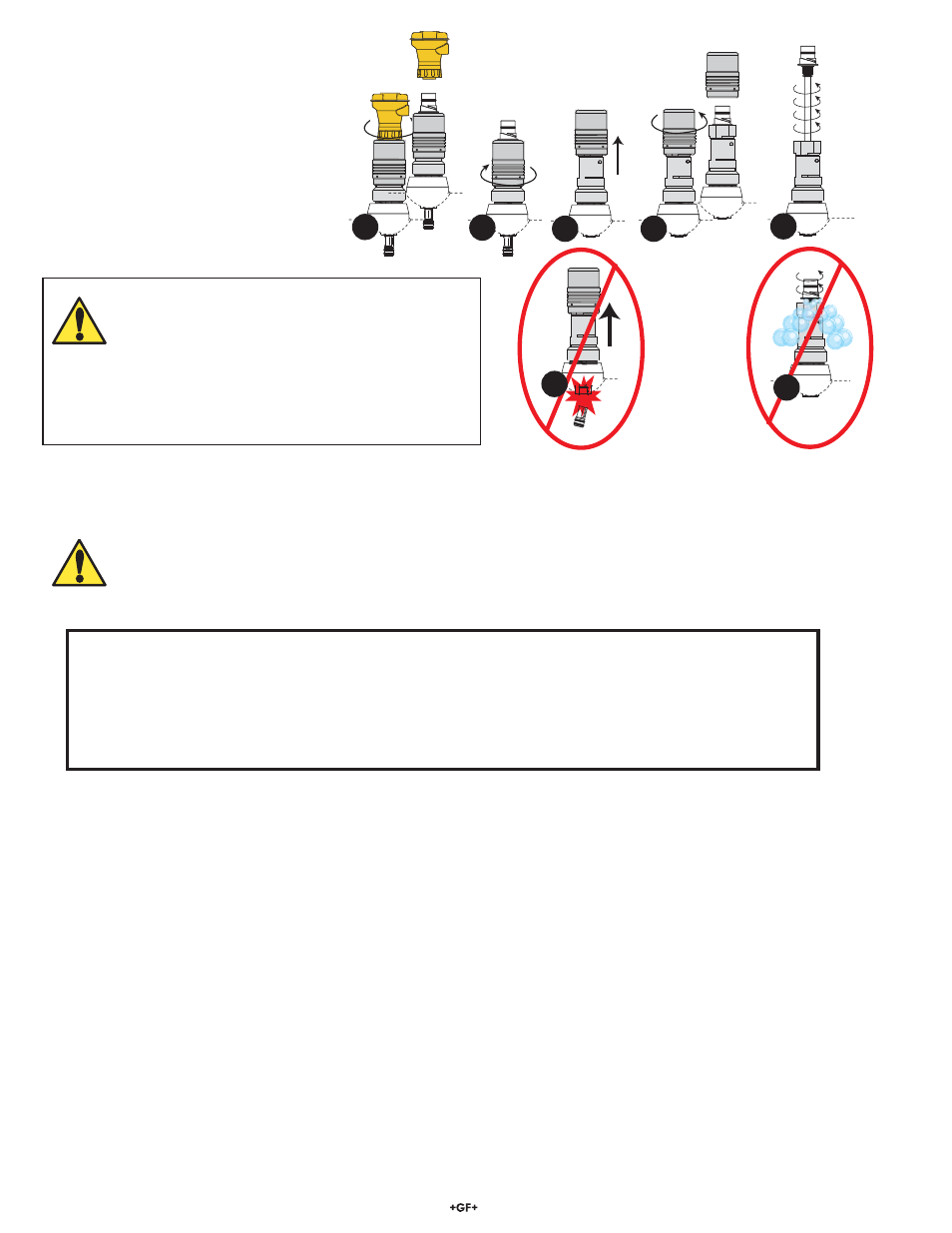

5.6 Electrode

Removal

The electrode in any pH or ORP system

requires periodic service, calibration or

replacement. When removing the electrode

from the wet-tap assembly, it is very important

to exercise caution and follow the instructions

carefully.

1.

Remove the preamplifi er from the top of

the wet-tap assembly.

2.

Turn the locking shroud

1

/

4

-turn clockwise

to unlock the piston.

3.

Pull up on the locking shroud to retract the

electrode piston into the pipe.

If the piston does not retract easily, or if any fl uid is observed leaking from the electrode

threads, the pipe must be drained before the 3719 can be safely removed.

•

Stop the fl ow and depressurize the pipe.

•

Remove the entire 3719 assembly from the pipe.

•

Remove the electrode from the assembly

•

Clean any scaling and debris found on or in the piston tip and surrounding area.

Cleaning

Cleaning techniques vary depending on the type of coating present on the glass electrode surface or reference junction.

•

Remove soft coatings by vigorous stirring, or with directed spray of a suitable detergent or solvent onto the glass electrode surface.

•

Use chlorine bleach or mild detergent to remove soft coatings. Rinse electrode tip in clean water after cleaning.

•

Use the least harsh chemical available to remove hard coatings without attacking the materials of construction.

(For example, remove calcium carbonate with a 5% HCL (muriatic acid) solution.

•

Remove oily or organic coatings with detergents or an appropriate solvent that does not attack the materials of construction.

•

ORP electrode surface (platinum) can be gently sanded with 600 grit wet and dry silicone or carbide sandpaper, jewelers rouge,

crocus cloth, or very fi ne steel wool.

•

Never scrape or sand the glass electrode surface.

•

Treat glass electrode surfaces with appropriate care to avoid breakage.

•

Lubricate O-rings with a non-petroleum based, viscous lubricant (grease) compatible with the system.

Wet-Tap Maintenance

•

The Wet-Tap assembly should be operated (retracted) on a monthly basis

•

The O-rings on the piston tip should be inspected and lubricated annually, and whenever the system is off line for maintenance.

•

Lubricate O-rings with a non-petroleum based, viscous, lubricant (grease) compatible with the system.

6. Electrode Maintenance and Cleaning

2

3

4

5

1

5

3

4.

Turn the locking shroud ¼-turn counterclockwise and lift up to remove it from the wet-tap assembly.

5.

Remove the electrode by turning it counterclockwise.

For safety, keep your body clear of the top of the wet-tap assembly while removing the electrode.

DANGER!

The piston should retract easily from a pressurized pipe.

If the piston offers resistance, there is a danger that the

piston is coated with deposits from the process.

STOP! DO NOT FORCE THE PISTON UP!

It may damage the O-rings or break off the piston tip.

Return the locking shroud to the LOCKED position and follow the

steps in the box below.

DANGER!

If any fl uid is observed leaking from the electrode threads, STOP! DO NOT REMOVE THE ELECTRODE.

There is a danger that the piston tip has been damaged.

Tighten the electrode back down to reseal the assembly and follow the steps in the box below.