Location of fitting rotor replacement procedure, Sensor mounting position, Standard sensor installation – GF Signet 515 Rotor-X Paddlewheel Flow Sensor User Manual

Page 5: Sensor wiring

5

Signet 515/2536 Rotor-X Flow Sensors

Sensor Installation and Wiring

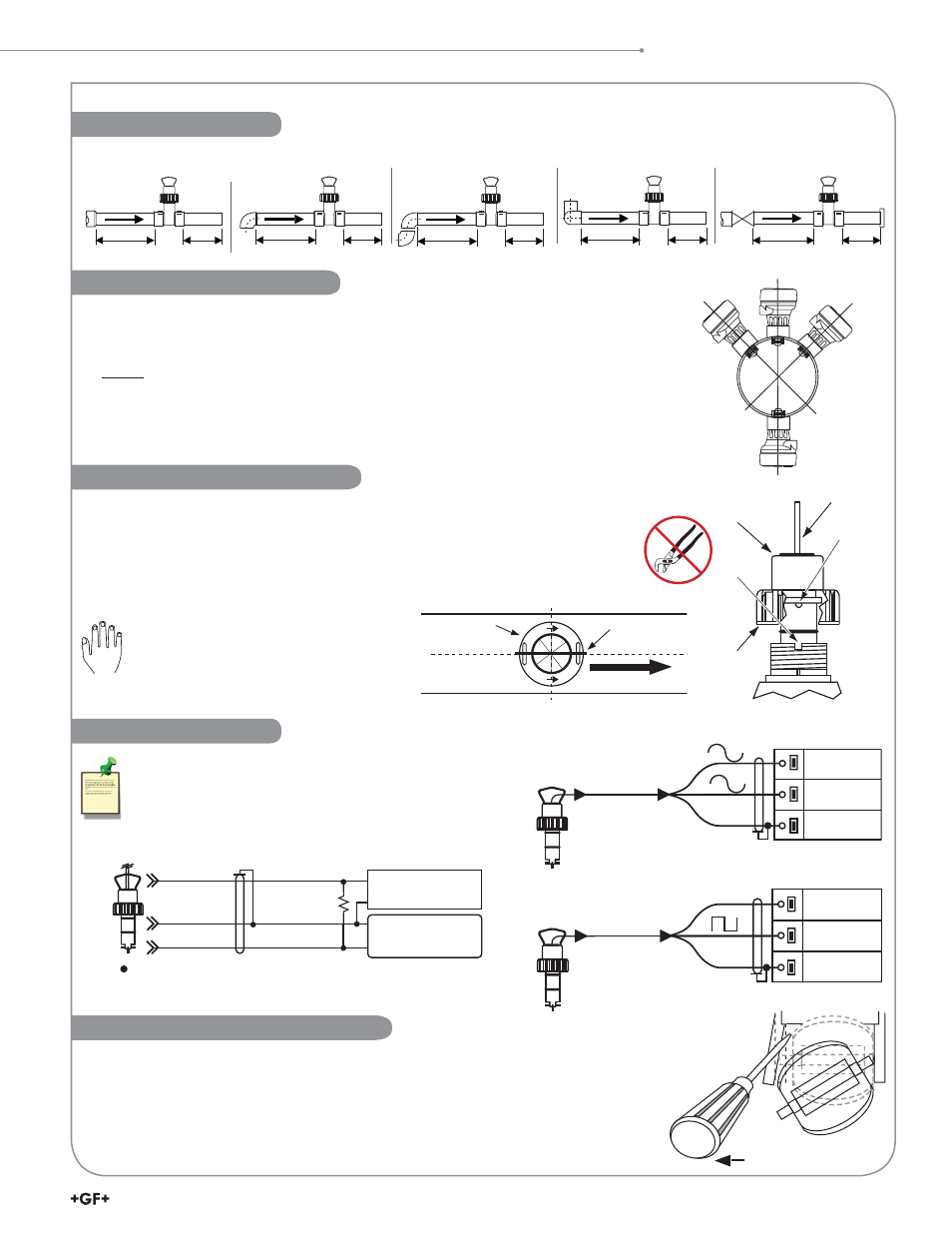

Recommended sensor upstream/downstream mounting requirements.

40x I.D.

5x I.D.

25x I.D.

5x I.D.

50x I.D.

5x I.D.

2 x 90° Elbow

3 dimensions

2 x 90° Elbow

Pump/Valve

15x I.D.

5x I.D.

20x I.D.

5x I.D.

Reducer

90° Elbow

Location of Fitting

Rotor Replacement Procedure

• To remove the rotor, insert a small screwdriver between the rotor and the ear of the sensor.

• Twist the screwdriver blade to fl ex the ear outward enough to remove one end of the rotor and pin.

• DO

NOT

fl ex the ear any more than necessary! If it breaks, the sensor cannot be repaired.

• Install the new rotor by inserting one tip of the pin into the hole,

then fl ex the opposite ear back enough to slip rotor into place.

Process

Pipe

+45°

-45°

0°

Horizontal pipe runs:

• Mount sensor in the upright (0°) position for best performance (pipe must be full).

• Mount at a maximum of 45° when air bubbles are present.

• Do not mount on the bottom of the pipe when sediments are present.

Vertical pipe runs:

• Mount sensor in any orientation.

• Upward

fl ow is preferred to ensure full pipe.

Sensor Mounting Position

sensor

bale

sensor

cap

tab

black

conduit

cap

notch

Figure B

black conduit

cap

PROCESS PIPE

(TOP VIEW)

direction of flow

sensor bale

Figure A

Standard Sensor Installation

Technical Notes

• Use 2-conductor shielded cable for cable extensions.

• Cable shield must be maintained through cable splice.

• Refer to your instrument manual for specifi c wiring details.

Black

Frequency (-)

Red

Frequency (+)

Shield

Ground

515 Sensor Connections to

Signet Instruments

Black

5 VDC

Red

Frequency in

Shield

Ground

2536 Sensor Connections to

Signet Instruments

10 K

+

-

Other Brands

2536 Sensor Connections to Other Brand Instruments

DC sensor power supplied from Signet instrument.

10 K

Pull-up resistor may be required for non-Signet brand instrument.

Input

Gnd.

3.3 to 24

VDC

Black

Shield

Red

Other

instrument

Sensor Wiring

• Lubricate O-rings with a non-petroleum based, viscous lubricant (grease)

compatible with the system.

• Using an alternating/twisting motion, lower the sensor into the fi tting, making sure the

installation arrows on the black cap are pointing in the direction of fl ow, see Figure A.

• Engage one thread of the sensor cap then turn the sensor until the alignment tab is

seated in the fi tting notch.

Hand tighten the sensor cap.

DO NOT use any tools on the sensor

cap or the cap threads and/or fi tting

fl ange threads will be damaged,

see Figure B.