Burkert Type 8041 User Manual

Page 21

19

INstallation

→

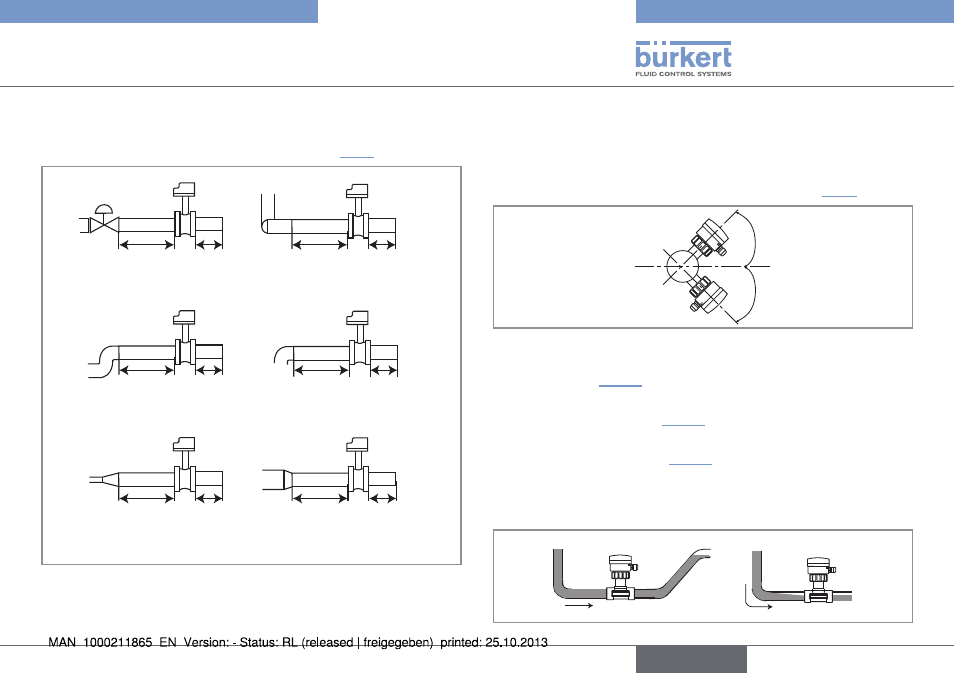

Install the device on the pipe to have the upstream and down-

stream distances respected according to the design of the

pipes, refer to standard EN ISO 5167-1 and Fig. 8:

50 x DN 5 x DN

40 x DN 5 x DN

25 x DN 5 x DN

20 x DN 5 x DN

18 x DN 5 x DN

15 x DN 5 x DN

With control valve

Pipe with 2 elbows at 90° in

3 dimensions

Pipe with 2 elbows at 90°

Pipe with 1 elbow at 90° or

1 T-piece

With pipe expansion

With pipe reduction

Fig. 8: Upstream and downstream distances depending on the

design of the pipes.

→

Respect the following additional mounting conditions to ensure

that the measuring device operates correctly:

- We recommend to install the device at a 45° angle to the hori-

zontal centre of the pipe to prevent deposits on the electrodes

and false measurements due to air bubbles (see Fig. 9);

45°

45°

Fig. 9: Mounting angle on the pipe

- Ensure that the pipe is always filled in the section around the

device (see Fig. 10).

- When mounting vertically ensure that the flow direction is in an

upward direction (see Fig. 10).

- Prevent the formation of air bubbles in the pipe in the section

around the device (see Fig. 11).

- Always mount the device upstream a possible injection point

in the pipe of a high-conductivity fluid (for example: acid, base,

saline,...).

Horizontal mounting

Correct

Incorrect

English

Type 8041