Installing a welding socket with radius, for mea, Suring devices with a g2'' nut, Installing a welding socket, for measuring – Burkert Type S020 User Manual

Page 34: Devices with a clamp connection

34

Installationandcommissioning

Type S020

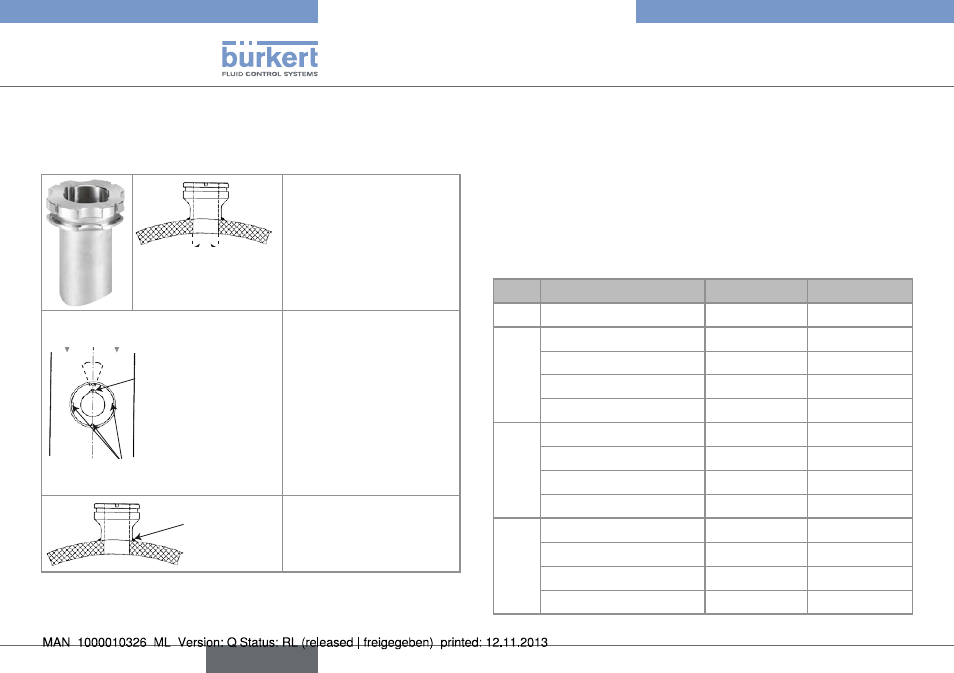

7.2.4. installing a welding socket with

radius, for measuring devices with a

g2'' nut

ø 28 mm

→

Drill a hole 28 mm in

diameter in the pipe.

Internal polarising

slot

External polarising

slots

α

α

→

Position the oblong

i n t e r n a l p o l a r i s i n g

slot opposite the flow

direction.

→

Align 2 of the 4 external

polarizing slots (a < 3°)

in the axis of the pipe.

Weld

→

Weld around the entire

circumference of the

welding socket with

radius.

Fig. 12: Installing a welding socket with radius

7.2.5. installing a welding socket, for

measuring devices with a clamp

connection

The welding socket can be installed:

• either on a T fitting with a short branch, installed into the pipe,

• or on the pipe which has previously been drilled and extruded to

shape a T fitting with a short branch.

→

Respect the following dimensions to drill and extrude the pipe:

DN

Standard

H

D

32

ISO4200

38.4

40

SMS 3008

3.0

35.6

BS 4828 / ASME BPE

2.5

34.8

DIN 11850 range 2

3.0

38

ISO4200

38.4

50

SMS 3008

3.0

35.6

BS 4828 / ASME BPE

2.5

34.8

DIN 11850 range 2

3.5

38

ISO4200

38.4

65

SMS 3008

3.0

35.6

BS 4828 / ASME BPE

4.0

34.8

DIN 11850 range 2

4.0

38

ISO4200

38.4

English